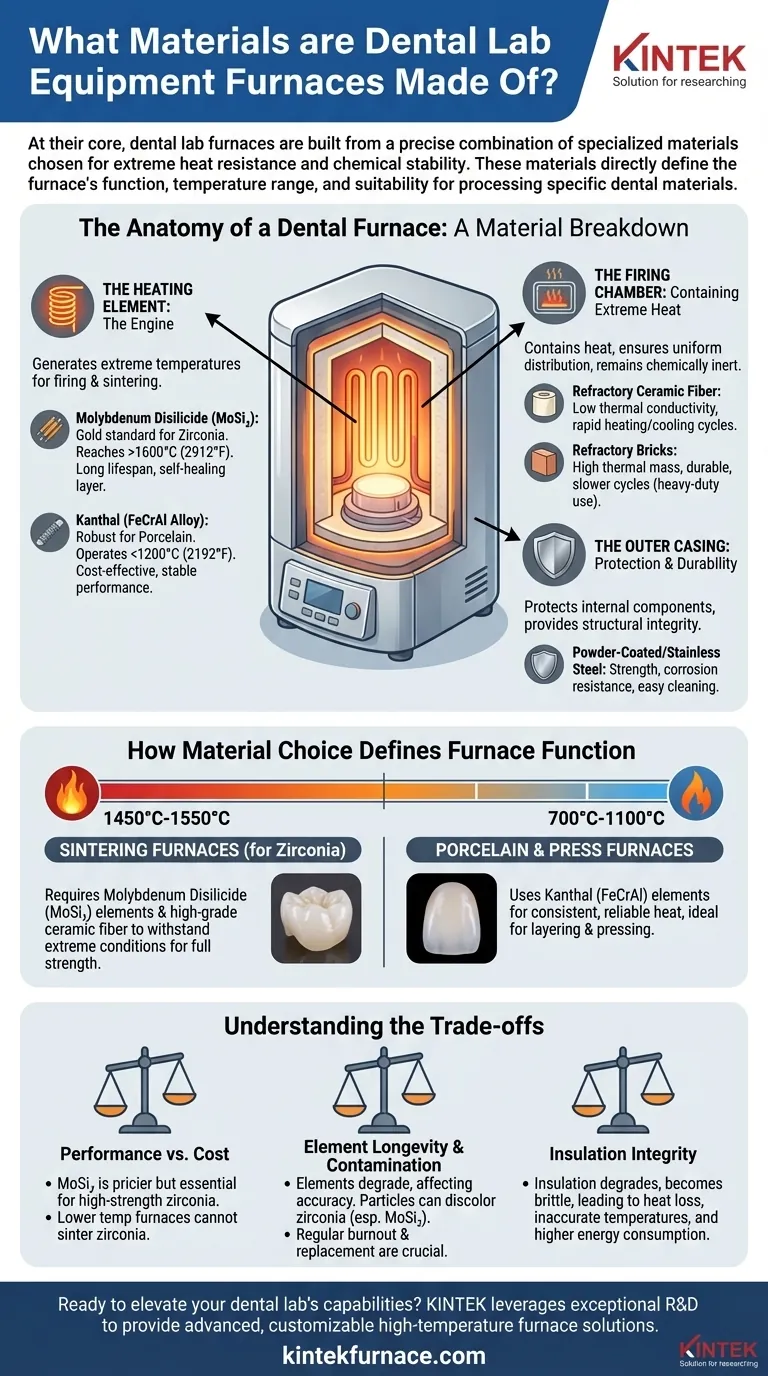

At their core, dental lab furnaces are built from a precise combination of specialized materials chosen for extreme heat resistance and chemical stability. The heating elements are typically made from advanced metallic compounds like Molybdenum Disilicide (MoSi₂) or Kanthal alloys, the internal chamber is lined with high-purity refractory ceramic insulation, and the external body is constructed from durable powder-coated or stainless steel.

The specific materials used in a dental furnace are not just a matter of quality; they directly define the furnace's function, temperature range, and suitability for processing specific dental materials like zirconia or porcelain. Understanding these components is key to evaluating a furnace's performance and longevity.

The Anatomy of a Dental Furnace: A Material Breakdown

A dental furnace is a system where each material plays a critical role. From generating heat to containing it safely, the composition of each component is engineered for a specific purpose.

The Heating Element: The Engine of the Furnace

The heating element is the heart of the furnace, responsible for generating the extreme temperatures required for firing and sintering. The material choice is dictated by the maximum required temperature.

-

Molybdenum Disilicide (MoSi₂): This is the gold standard for high-temperature sintering furnaces used for zirconia. MoSi₂ elements can reliably reach temperatures in excess of 1600°C (2912°F) and are known for their long lifespan and ability to form a protective, self-healing layer of silica glass at high temperatures.

-

Kanthal (FeCrAl Alloy): This iron-chromium-aluminum alloy is a robust and cost-effective choice for porcelain furnaces, which operate at lower temperatures, typically below 1200°C (2192°F). It provides excellent stability and performance within this range.

The Firing Chamber: Containing Extreme Heat

The internal chamber, or muffle, must contain the heat generated by the elements, ensure uniform temperature distribution, and remain chemically inert to avoid contaminating the dental restorations.

-

Refractory Ceramic Fiber: Most modern furnaces use high-purity, vacuum-formed ceramic fiber insulation. This material has extremely low thermal conductivity, allowing for rapid heating and cooling cycles while keeping the furnace's exterior cool.

-

Refractory Bricks: Some heavy-duty or older furnaces may use dense, insulating firebricks made from alumina or other refractory oxides. While durable, they have higher thermal mass, meaning they heat up and cool down more slowly.

The Outer Casing: Protection and Durability

The external body protects the sensitive internal components from the lab environment and provides structural integrity.

- Powder-Coated or Stainless Steel: These materials are used for the outer shell due to their strength, corrosion resistance, and ease of cleaning. A steel frame provides the rigidity needed to support the delicate internal components.

How Material Choice Defines Furnace Function

The different types of dental furnaces are defined almost entirely by the temperature capabilities of their materials.

Sintering Furnaces (for Zirconia)

To achieve full strength, zirconia frameworks must be sintered at temperatures between 1450°C and 1550°C. This mandates the use of Molybdenum Disilicide (MoSi₂) heating elements and high-grade ceramic fiber insulation that can withstand these extreme conditions without degrading.

Porcelain & Press Furnaces

Layering dental porcelain or pressing ceramic ingots occurs at significantly lower temperatures, usually between 700°C and 1100°C. For these applications, furnaces equipped with Kanthal (FeCrAl) elements provide consistent, reliable heat and are the most economical and effective choice.

Understanding the Trade-offs

Choosing or evaluating a furnace involves understanding the compromises inherent in its material design.

Performance vs. Cost

Furnaces with MoSi₂ elements are more expensive, but they are the only option for processing high-strength zirconia. Attempting to use a lower-temperature porcelain furnace for sintering will not work and can destroy the equipment.

Element Longevity and Contamination

All heating elements degrade over time. As they age, their resistance changes, which can affect temperature accuracy. More critically, they can release microscopic particles that may discolor zirconia restorations, especially with MoSi₂ elements. This is why regular "burnout" cycles and eventual element replacement are crucial for quality control.

Insulation Integrity

The ceramic fiber insulation can also degrade, becoming brittle and less effective. This leads to heat loss, inaccurate firing temperatures, and increased energy consumption. High-purity insulation is more resistant to shrinkage and devitrification, offering a longer and more stable service life.

Making the Right Choice for Your Lab's Needs

Your decision should be guided by the primary dental materials you work with.

- If your primary focus is high-strength zirconia restorations: You must invest in a sintering furnace with Molybdenum Disilicide (MoSi₂) heating elements and high-purity insulation.

- If your primary focus is conventional porcelain-fused-to-metal (PFM) or pressable ceramics: A reliable porcelain furnace with Kanthal (FeCrAl) elements is the industry standard and will meet all your technical needs.

- If your primary focus is versatility and future-proofing: Consider a lab setup with dedicated furnaces for each process to avoid cross-contamination and ensure each unit is optimized for its specific task.

Understanding these core materials empowers you to look beyond marketing and evaluate a furnace on its fundamental ability to deliver precise, repeatable results.

Summary Table:

| Component | Material | Key Properties | Common Uses |

|---|---|---|---|

| Heating Element | Molybdenum Disilicide (MoSi₂) | High temp resistance (>1600°C), self-healing | Zirconia sintering |

| Heating Element | Kanthal (FeCrAl Alloy) | Cost-effective, stable up to 1200°C | Porcelain firing |

| Firing Chamber | Refractory Ceramic Fiber | Low thermal conductivity, rapid heating/cooling | Modern furnaces |

| Firing Chamber | Refractory Bricks | High durability, slower thermal cycles | Heavy-duty furnaces |

| Outer Casing | Powder-Coated/Stainless Steel | Corrosion resistance, easy cleaning | Structural protection |

Ready to elevate your dental lab's capabilities? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization to precisely meet your unique experimental needs, whether you're sintering zirconia or firing porcelain. Don't compromise on precision and efficiency—contact us today to discuss how our furnaces can enhance your workflow and deliver superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations