In short, box-type atmosphere furnaces are highly versatile, designed to process a wide range of materials including metals, alloys, ceramics, and advanced composites. They are engineered for critical heat treatment processes like annealing, sintering, quenching, and solution treatment, where controlling the gaseous environment is essential to the final outcome.

The decision to use a box-type atmosphere furnace is not about the shape of the furnace, but about the absolute need to control the chemical environment during heat treatment. Its purpose is to prevent unwanted reactions like oxidation and to enable specific surface modifications that are impossible in open air.

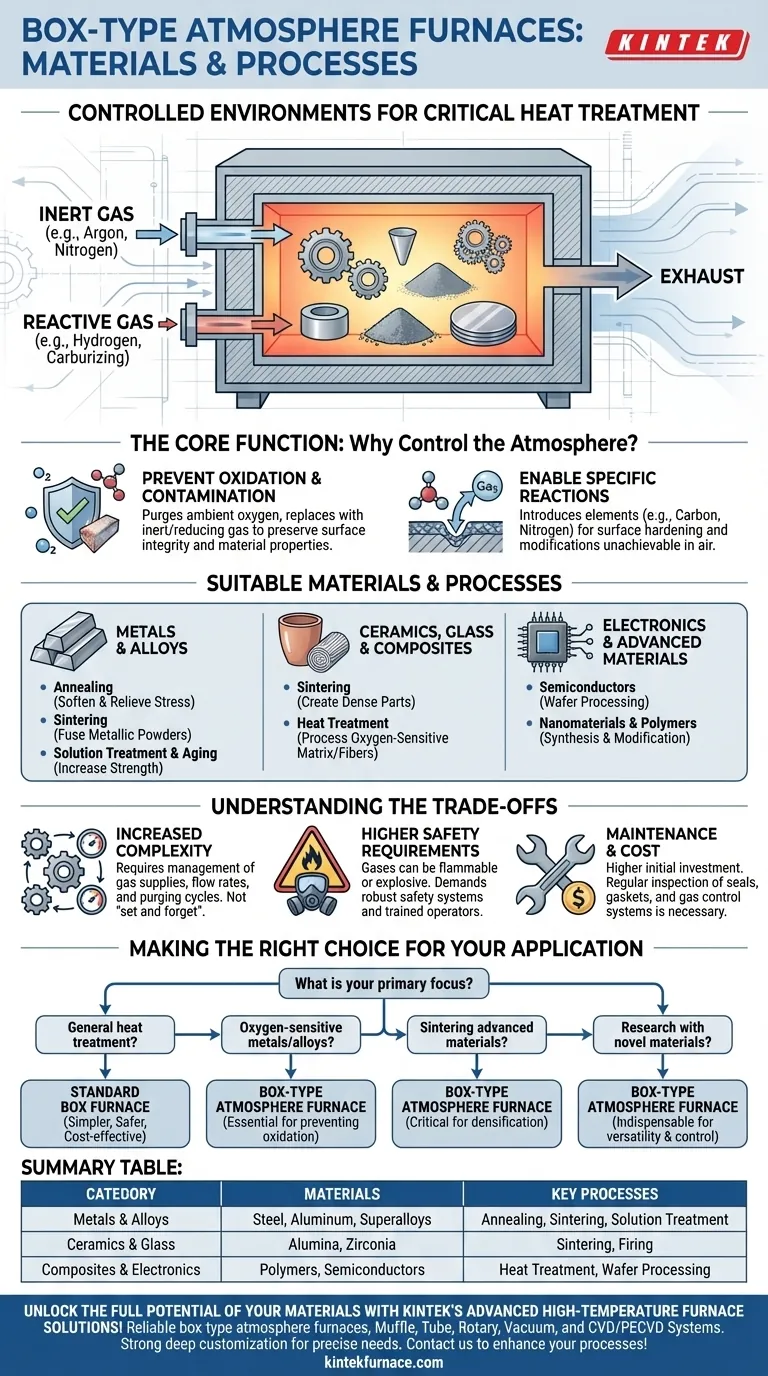

The Core Function: Why Control the Atmosphere?

The defining feature of an atmosphere furnace is its sealed chamber, which allows you to replace the ambient air with a specific, controlled gas. This capability is not a minor detail; it is fundamental to achieving desired material properties.

Preventing Oxidation and Contamination

At elevated temperatures, most materials—especially metals—react readily with oxygen in the air. This causes scaling, discoloration, and degradation of the material's properties.

An atmosphere furnace purges the oxygen and replaces it with an inert gas (like Argon or Nitrogen) or a reducing gas (like Hydrogen) to create a protective environment. This ensures the material's surface remains clean and its integrity is preserved.

Enabling Specific Material Reactions

For some processes, the atmosphere is not just protective but is an active ingredient. The furnace's controlled environment is used to introduce specific elements to a material's surface.

Processes like carburizing (adding carbon) or nitriding (adding nitrogen) rely on a reactive gas atmosphere to create a hardened surface layer on steel components, a result unachievable in a standard furnace.

Suitable Materials and Processes in Detail

The furnace's versatility makes it a cornerstone in both industrial production and advanced research.

Metals and Alloys

This is the most common application. The furnace is used for processes that define the mechanical properties of metals.

- Annealing: Heating and slowly cooling to soften metals, relieve internal stresses, and improve ductility.

- Sintering: Fusing metallic powders together below their melting point to create solid components, a key process in powder metallurgy.

- Solution Treatment & Aging: A two-step process, primarily for aluminum and superalloys, to increase strength and hardness.

Ceramics, Glass, and Composites

These materials often require precise temperature ramps and clean processing environments.

- Sintering: Firing shaped ceramic powders (like alumina or zirconia) to create dense, hard final parts. The atmosphere prevents reactions that could compromise the ceramic's integrity.

- Heat Treatment: Processing composite materials where either the matrix or reinforcing fibers are sensitive to oxygen at high temperatures.

Electronics and Advanced Materials

The high-purity environment is critical for manufacturing and research.

- Semiconductors: Used in certain steps of wafer processing where a specific, non-oxidizing environment is required.

- Nanomaterials & Polymers: Researchers use these furnaces for preparing and modifying novel materials that are highly reactive or require an ultra-clean environment.

Understanding the Trade-offs

Choosing an atmosphere furnace involves accepting a higher degree of complexity compared to a standard air furnace.

Increased Operational Complexity

A standard box furnace is often a "set and forget" device. In contrast, an atmosphere furnace requires managing gas supplies, flow rates, and purging cycles. Operators must ensure the chamber is properly sealed and that the desired atmosphere is established and maintained.

Higher Safety Requirements

The gases used, such as hydrogen or cracked ammonia, are often flammable or explosive. This necessitates robust safety systems.

Proper installations require gas monitoring, leak detectors, explosion-proof components, and emergency ventilation. Most importantly, it demands professionally trained operators who understand the risks and safety protocols.

Maintenance and Cost

The addition of gas control systems, seals, and safety interlocks increases the initial cost and the ongoing maintenance burden. Gaskets and seals degrade over time and require regular inspection and replacement to ensure the chamber remains airtight.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on the material requirements and the operational environment.

- If your primary focus is general heat treatment without strict atmospheric control: A standard box furnace is simpler, safer, and more cost-effective for tasks like tempering steel or firing basic ceramics.

- If your primary focus is processing oxygen-sensitive metals or alloys: A box-type atmosphere furnace is essential for preventing oxidation and achieving desired properties through annealing or aging.

- If your primary focus is sintering advanced ceramics or metal powders: The controlled inert or reducing atmosphere is critical for achieving full densification and preventing unwanted chemical reactions.

- If your primary focus is research with novel or reactive materials: The furnace's versatility in handling various gases and precise process control makes it an indispensable tool for experimentation.

Ultimately, understanding these core principles ensures you select a furnace that is not just capable, but perfectly suited to your technical and operational goals.

Summary Table:

| Category | Materials | Key Processes |

|---|---|---|

| Metals & Alloys | Steel, Aluminum, Superalloys | Annealing, Sintering, Solution Treatment |

| Ceramics & Glass | Alumina, Zirconia | Sintering, Firing |

| Composites & Electronics | Polymers, Semiconductors | Heat Treatment, Wafer Processing |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable box-type atmosphere furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, such as annealing, sintering, or handling reactive materials. Contact us today to discuss how we can enhance your processes and deliver superior results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity