At its core, a muffle furnace's versatility stems from its fundamental design: an insulated outer chamber that heats an isolated inner chamber, or "muffle." This simple but effective separation allows it to provide a clean, controlled, and precise high-temperature environment. This core function is a universal requirement across dozens of scientific, analytical, and industrial processes.

The key to the muffle furnace's adaptability is its ability to separate the material being heated from the heating elements themselves. This prevents contamination from combustion gases or electrical arcing, ensuring the purity of the sample and the integrity of the process.

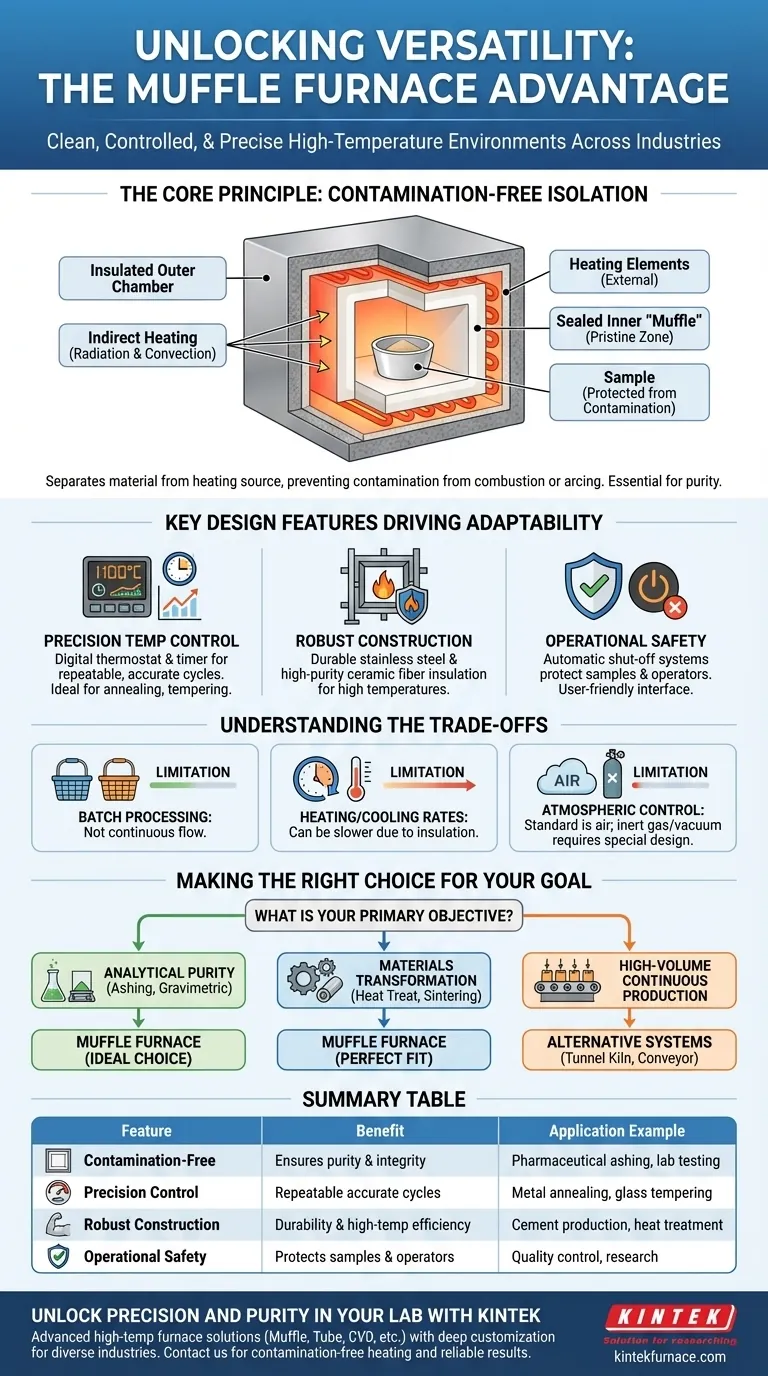

The Core Principle: A Contamination-Free Environment

The name "muffle furnace" itself reveals its primary advantage. The design is centered on creating a pristine heating zone, which is a non-negotiable requirement for many sensitive applications.

What “Muffle” Means

A muffle is a sealed, high-temperature-resistant chamber (often ceramic) that contains the material being processed. This chamber is placed inside the main furnace and is heated externally by the heating elements.

The sample inside the muffle is only heated by radiation and convection, never by direct contact with the heat source.

Preventing Cross-Contamination

This isolation is critical. In fuel-fired furnaces, it prevents byproducts of combustion from reacting with the sample. In electric furnaces, it protects sensitive materials from any potential arcing or particle shedding from the heating coils.

This guarantees that the thermal process itself is the only variable, a requirement for reliable analytical testing in fields like pharmaceuticals and environmental science.

Key Design Features Driving Adaptability

Beyond the core principle of isolation, modern muffle furnaces incorporate several features that make them a practical and reliable tool for a wide range of users.

Precision Temperature Control

Most units are equipped with a digital thermostat and timer. Paired with thick insulating walls and well-sealed doors, this allows for extremely precise and repeatable temperature cycles.

This level of control is essential for processes like metal annealing, glass tempering, or the ashing of organic materials, where slight temperature deviations can ruin the final product.

Robust Construction for High Temperatures

Muffle furnaces are built for durability in demanding environments. Housings are often made of textured stainless steel, and the internal chamber uses high-purity ceramic fiber insulation.

This robust construction ensures a long operational life and the ability to maintain very high temperatures (often over 1100°C) efficiently and safely, making them suitable for industrial settings like cement production or metal heat treatment.

Operational Safety and Usability

Features like automatic shut-off systems prevent overheating and protect both the sample and the operator. Modern designs also focus on user-friendly interfaces and sometimes include self-cleaning functions, which simplify maintenance.

Understanding the Trade-offs

While highly versatile, muffle furnaces are not the universal solution for all high-temperature needs. Understanding their limitations is key to using them correctly.

Batch Processing, Not Continuous Flow

A muffle furnace is fundamentally a batch-processing tool. You load a sample, run a cycle, and then unload it. It is not designed for continuous, assembly-line-style production.

Heating and Cooling Rates

The same thick insulation that makes them efficient also means they can have relatively slow heat-up and cool-down times compared to other furnace types like induction furnaces. This must be factored into process scheduling.

Atmospheric Control

A standard muffle furnace operates with a normal air atmosphere. While this is sufficient for most applications, processes requiring a specific inert gas (like argon or nitrogen) or a vacuum need a specially designed furnace with gas ports and vacuum seals.

Making the Right Choice for Your Goal

To determine if a muffle furnace is the correct tool, consider your primary objective.

- If your primary focus is analytical purity: A muffle furnace is the ideal choice for applications like ashing, gravimetric analysis, or sample preparation where avoiding contamination is paramount.

- If your primary focus is materials transformation: Its precise temperature control makes it perfect for heat treating, annealing, or sintering small parts where consistent material properties are the goal.

- If your primary focus is high-volume, continuous production: You should investigate alternative systems like a tunnel kiln or conveyor furnace that are better suited for industrial-scale throughput.

By providing a pure and precisely controlled heating environment, the muffle furnace empowers professionals across countless industries to achieve reliable and repeatable results.

Summary Table:

| Feature | Benefit | Application Example |

|---|---|---|

| Contamination-Free Environment | Ensures sample purity and process integrity | Pharmaceutical ashing, environmental testing |

| Precision Temperature Control | Enables repeatable and accurate thermal cycles | Metal annealing, glass tempering |

| Robust Construction | Provides durability and high-temperature efficiency | Cement production, industrial heat treatment |

| Operational Safety | Protects samples and operators with automatic shut-offs | Laboratory research, quality control |

Unlock Precision and Purity in Your Lab with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in pharmaceuticals, materials science, or industrial processing, we deliver tailored solutions for contamination-free heating, precise temperature control, and enhanced safety.

Contact us today to discuss how our muffle furnaces and other products can optimize your processes and drive reliable results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure