At its core, a box furnace's versatility stems from its fundamental design simplicity, which allows it to be adapted across an exceptionally wide range of sizes, temperatures, and applications. This adaptability makes it an indispensable tool for both industrial manufacturing and scientific research, capable of handling diverse materials and thermal processes with high reliability and ease of use.

A box furnace is the quintessential "workhorse" of thermal processing. Its value lies not in being the most specialized tool for a single task, but in being a highly capable and adaptable platform for a multitude of common heating applications.

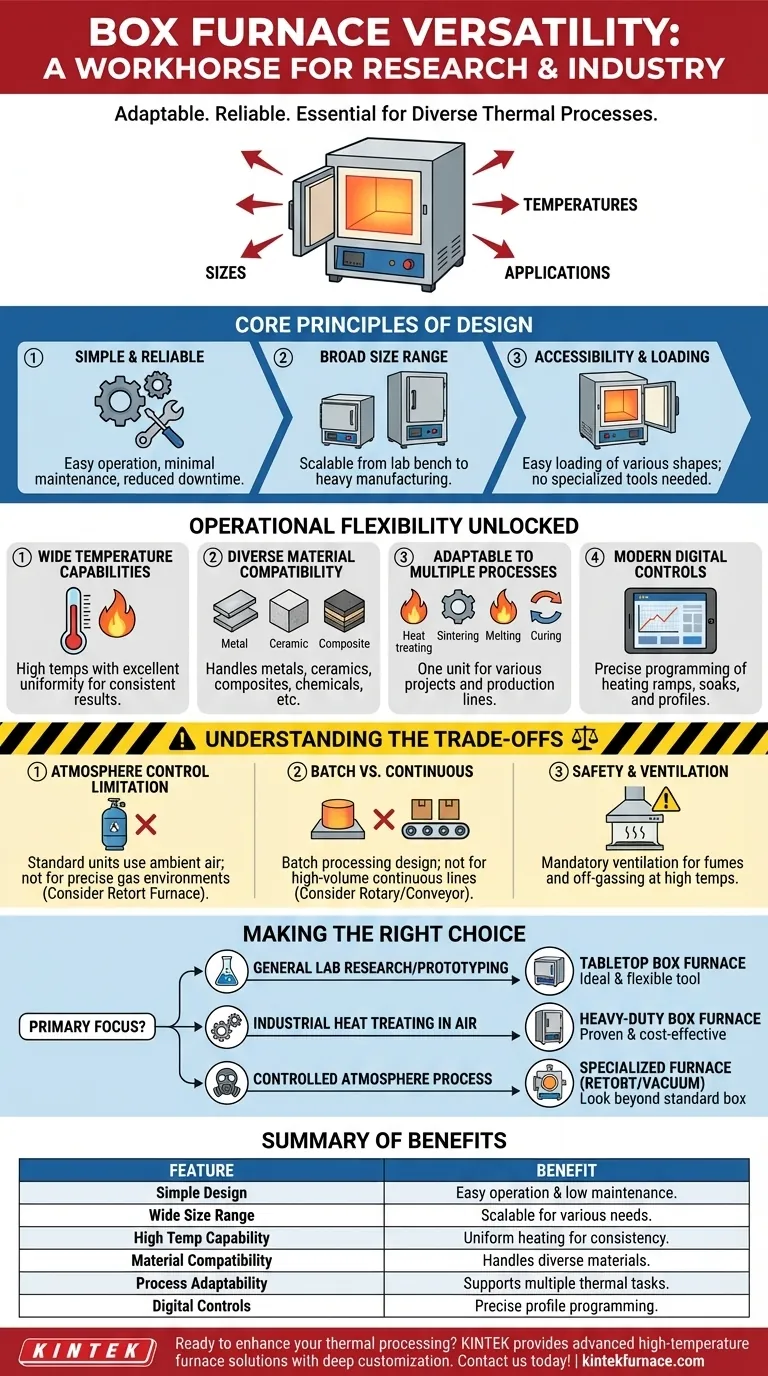

Core Principles of Box Furnace Design

The versatility of a box furnace is not an accident; it is a direct result of an intentionally simple and scalable engineering approach. This design philosophy prioritizes reliability and broad utility over narrow specialization.

Simplicity and Reliability

The straightforward, chamber-based design of a box furnace minimizes complexity. This results in equipment that is famously easy to operate and requires minimal maintenance, reducing operational overhead and downtime.

Broad Range of Sizes

Box furnaces are not a one-size-fits-all solution. They scale from compact, tabletop models ideal for small labs to massive, multi-level industrial units for heavy manufacturing, ensuring a suitable configuration exists for nearly any operational need.

Accessibility and Loading

Designers prioritize ease of access. Features like large vertical-lift or swing-out doors are common, allowing operators to easily load and unload products of various shapes and sizes without specialized equipment.

Unpacking the Operational Flexibility

Beyond the physical design, the operational capabilities of a box furnace are what truly unlock its potential across different fields.

Wide Temperature Capabilities

A key characteristic is the ability to achieve high temperatures, often with excellent temperature uniformity throughout the chamber. This ensures that materials are processed consistently, which is critical for processes like sintering and heat treating.

Diverse Material Compatibility

From metals and ceramics to composites and chemicals, the fundamental heating mechanism of a box furnace is compatible with a vast array of materials. This allows a single unit to serve many different projects or production lines.

Adaptable to Multiple Processes

The same furnace can be used for heat treatment (like annealing or tempering), sintering powders, melting alloys, curing composites, or conducting fundamental materials research. This process diversity makes it a cost-effective investment.

Modern Control and Customization

Modern box furnaces feature user-friendly digital control interfaces that allow for precise programming of heating ramps, soaks, and cooling profiles. High customization options are often available, allowing users to specify features that meet their exact needs.

Understanding the Trade-offs

While highly versatile, the box furnace is not the optimal solution for every thermal process. Understanding its inherent trade-offs is crucial for proper selection.

The Atmosphere Control Limitation

A standard box furnace operates in ambient air. While some can be modified with gas ports, they are not inherently designed for the precise atmosphere control needed for sensitive processes. For applications requiring a specific inert or reactive gas environment, a retort furnace is a more suitable choice.

Batch vs. Continuous Processing

By design, a box furnace is a batch processor. Materials are loaded, heated, and then unloaded. For high-volume, continuous production lines, a rotary furnace or conveyor furnace would be a more efficient solution.

Safety and Ventilation

Operating at high temperatures often creates fumes or off-gassing from the materials being processed. Proper ventilation, such as a dedicated fume hood or local exhaust system, is a mandatory safety consideration that must be planned for.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your primary objective.

- If your primary focus is general lab research or prototyping: The wide temperature range and ease of use of a tabletop box furnace make it an ideal and flexible tool.

- If your primary focus is industrial heat treating in air: The robustness, reliability, and scalability of a heavy-duty box furnace offer a proven and cost-effective solution.

- If your primary focus is a process requiring a controlled atmosphere: You should look beyond a standard box furnace to a specialized retort or vacuum furnace.

Ultimately, the box furnace's enduring value comes from providing a reliable and adaptable foundation for countless thermal processing tasks.

Summary Table:

| Feature | Benefit |

|---|---|

| Simple Design | Easy operation and low maintenance for reduced downtime |

| Wide Size Range | Scalable from tabletop to industrial units for various needs |

| High Temperature Capability | Achieves uniform heating for consistent material processing |

| Material Compatibility | Handles metals, ceramics, composites, and chemicals |

| Process Adaptability | Supports heat treatment, sintering, melting, and curing |

| Digital Controls | Precise programming for heating and cooling profiles |

Ready to enhance your thermal processing with a versatile box furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and industries with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet your unique experimental and production requirements. Contact us today to discuss how our tailored solutions can boost your efficiency and reliability!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- How is a muffle furnace utilized for AlN crystal post-processing? Optimize Surface Purity via Staged Oxidation

- What is the function of laboratory high-temperature box furnaces in T6 aluminum treatment? Key to Material Strength