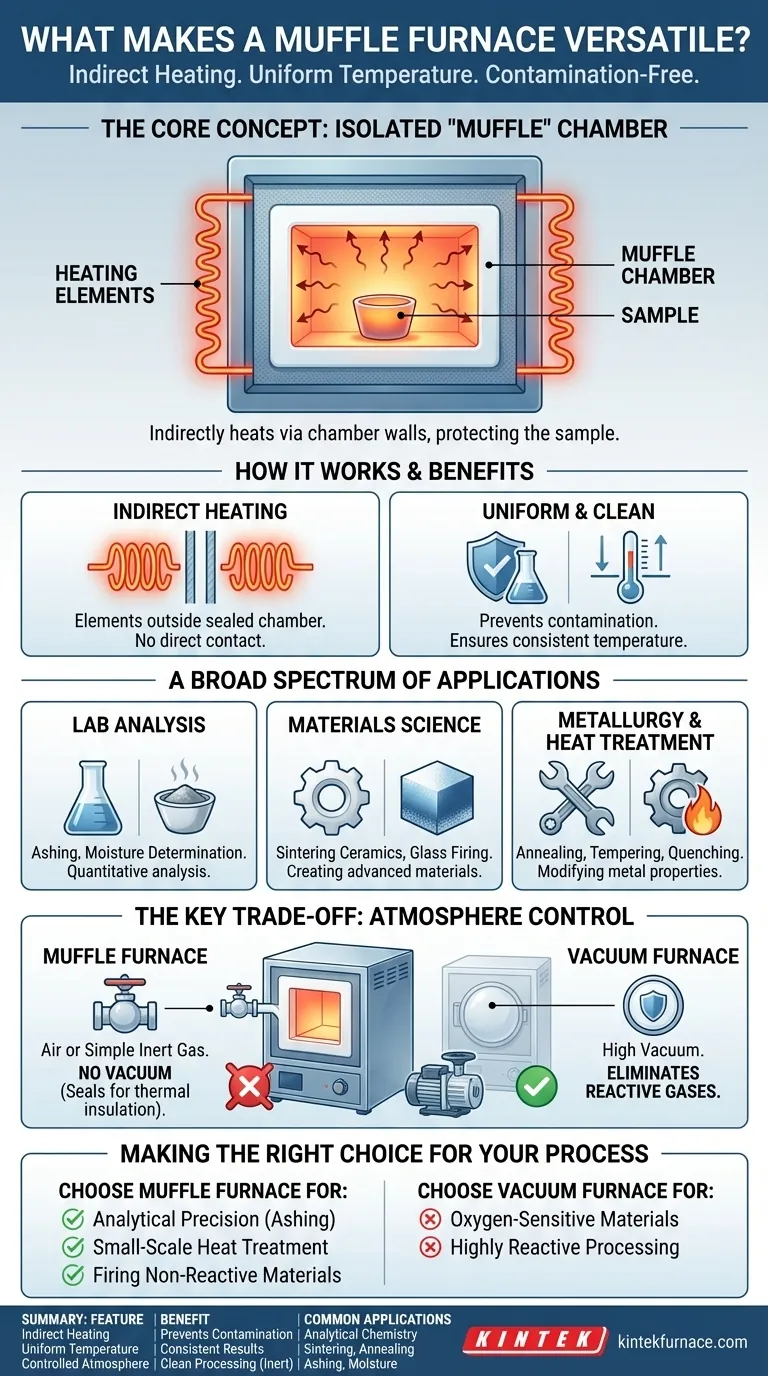

At its core, a muffle furnace’s versatility stems from its fundamental design: it uses indirect heating within a controlled chamber. This allows it to achieve precise, uniform high temperatures for a vast range of material processing tasks, from analytical chemistry to metallurgy, while protecting the sample from direct contact with the heating elements and their byproducts.

The key to its adaptability is the "muffle"—an isolated inner chamber that separates the material being heated from the furnace's heating source. This simple but powerful concept enables clean, repeatable thermal processing for nearly any material that doesn't require a vacuum.

The Design Principle: Indirect, Contamination-Free Heat

The term "muffle" refers to the furnace's core feature: a separate, enclosed chamber that contains the sample. This design is the primary driver of its versatility.

How the Muffle Works

The heating elements, typically made of alloys like Kanthal or Nichrome, are positioned outside this sealed inner chamber. They heat the chamber, which in turn radiates heat evenly onto the sample inside.

This indirect heating method is what separates a muffle furnace from simpler ovens or kilns where the sample might be exposed to the byproducts of combustion or direct radiation from glowing elements.

Preventing Sample Contamination

By isolating the sample, the muffle ensures that no contaminants from the heating elements or the surrounding atmosphere can interfere with the process. This is critical for analytical applications where purity is paramount.

Ensuring Uniform Temperature

The chamber acts as a heat distributor, smoothing out hot spots and ensuring the entire sample experiences a uniform temperature. This is essential for consistent results in processes like sintering ceramics or annealing metals, where uneven heating can ruin the final product.

A Broad Spectrum of Applications

The combination of high heat, precise control, and a clean environment makes the muffle furnace a workhorse in numerous fields.

Laboratory Analysis

In food, environmental, and pharmaceutical labs, muffle furnaces are indispensable for quantitative analysis. They are used for ashing, the process of burning off all organic matter to determine the non-combustible ash content of a sample, and for precise moisture determination.

Materials Science and Firing

The furnace is used for sintering, a process where heat is applied to a powdered material to form a solid mass without melting it. This is fundamental to creating ceramics, glass, and other advanced materials.

Metallurgy and Heat Treatment

In industrial settings, muffle furnaces perform various heat treatments on small metal parts. These processes modify the material's physical and sometimes chemical properties.

- Annealing: Softens metal to make it easier to work with.

- Tempering: Increases the toughness of hardened steel.

- Quenching: Rapidly cools a workpiece to achieve specific material properties.

Understanding the Key Trade-off: Atmosphere Control

While incredibly versatile, a muffle furnace has one primary limitation that defines its scope of use.

The Inability to Create a Vacuum

Standard muffle furnaces are not designed to operate under a vacuum. The seals are built for thermal insulation, not for holding negative pressure.

For processes involving materials that are highly reactive with air, even at high temperatures, a vacuum furnace is the necessary alternative. A vacuum environment eliminates oxygen and other gases that could cause unwanted oxidation or contamination.

Limited Atmosphere Modification

While some advanced models allow for the introduction of an inert gas like nitrogen or argon to create a controlled atmosphere, they are not a substitute for a true vacuum or reactive gas furnace. Their primary function remains heating in ambient air or a simple inert environment.

Making the Right Choice for Your Process

Your specific goal determines whether a muffle furnace is the correct instrument.

- If your primary focus is analytical precision (ashing, moisture analysis): A standard muffle furnace is the ideal and most cost-effective tool for the job.

- If your primary focus is small-scale heat treatment or firing non-reactive materials: A muffle furnace offers the necessary temperature control and uniformity for excellent results.

- If your primary focus is processing oxygen-sensitive or highly reactive materials: You must use a vacuum furnace to prevent unwanted chemical reactions and ensure material integrity.

Understanding this distinction empowers you to select the right tool for your specific thermal processing needs.

Summary Table:

| Feature | Benefit | Common Applications |

|---|---|---|

| Indirect Heating | Prevents sample contamination from heating elements | Analytical chemistry, material testing |

| Uniform Temperature | Ensures consistent results in thermal processes | Sintering ceramics, annealing metals |

| Controlled Atmosphere | Allows for clean processing in inert environments | Laboratory ashing, moisture determination |

| High-Temperature Capability | Supports a wide range of material processing tasks | Metallurgy, glass firing, small-scale heat treatment |

Ready to enhance your lab's capabilities with a versatile muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet unique experimental requirements. Whether you're in analytical chemistry, materials science, or metallurgy, we can help you achieve precise, contamination-free heating. Contact us today to discuss how our solutions can benefit your specific applications!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?