For any sintering furnace, a proactive maintenance schedule is essential for ensuring both the quality of your restorations and the longevity of the equipment. Key maintenance tasks include the regular inspection of heating elements, routine cleaning of the furnace chamber, checking insulation integrity, verifying all gas and power lines, and periodically calibrating temperature sensors.

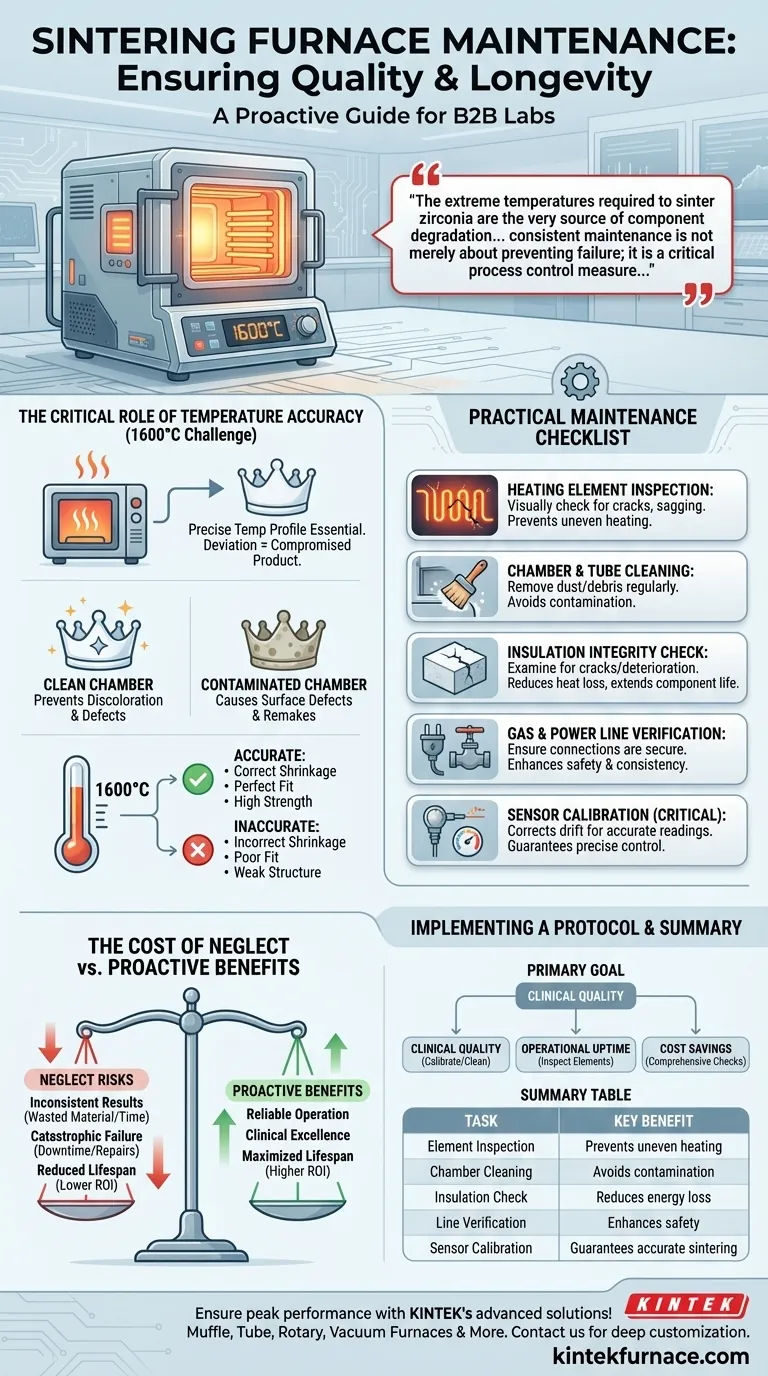

The extreme temperatures required to sinter zirconia are the very source of component degradation over time. Therefore, consistent maintenance is not merely about preventing failure; it is a critical process control measure to guarantee the accuracy, fit, and clinical success of every restoration you produce.

The Critical Role of Temperature Accuracy

A sintering furnace's primary job is to execute a precise time-and-temperature profile. Any deviation from this profile directly compromises the final product.

Why 1600°C Changes Everything

Sintering furnaces operate at extreme temperatures, often up to 1600°C, to transform milled zirconia from a porous, chalk-like state into a dense, high-strength ceramic.

This intense heat places enormous stress on every component, from the heating elements that generate it to the insulation that contains it and the sensors that measure it.

The Link Between Temperature and Zirconia Properties

The sintering process causes the zirconia to shrink significantly as porosity is eliminated and density increases. This shrinkage is precisely calculated and accounted for in the initial milling stage.

If the furnace temperature is inaccurate—even by a small margin—the shrinkage will be incorrect. This can lead to restorations that do not fit, have poor marginal integrity, or possess compromised structural strength.

The Threat of Contamination

The furnace chamber must be kept impeccably clean. Debris from previous cycles or foreign contaminants can vaporize at high temperatures and settle on the surface of the zirconia.

This contamination can cause discoloration, spots, or surface defects, rendering the restoration clinically unacceptable and requiring a costly remake.

A Practical Maintenance Checklist

A disciplined maintenance routine is the most effective way to ensure reliable furnace operation. This should be a documented process within your facility.

Heating Element Inspection

Heating elements are consumable components that degrade with every cycle. Visually inspect them for any signs of cracking, sagging, or discoloration. Degrading elements lead to uneven heating or an inability to reach the target temperature, ruining the sintering cycle.

Furnace Chamber and Tube Cleaning

Regularly clean the furnace chamber or firing tube according to the manufacturer's instructions. This removes any dust or debris that could contaminate future cycles, ensuring the aesthetic quality of your zirconia restorations.

Insulation Integrity Check

Examine the furnace's insulation for any cracks or deterioration. Damaged insulation leads to heat loss, forcing the furnace to work harder, consume more energy, and potentially shorten the life of the heating elements.

Gas and Power Line Verification

Periodically check that all power cords and any gas lines are secure and show no signs of wear or damage. This is a fundamental safety check that also ensures consistent operational power.

Sensor and Thermocouple Calibration

This is arguably the most critical maintenance task. The thermocouple is the sensor that reports the internal temperature to the furnace controller. Over time, all thermocouples "drift" and become less accurate.

Regular calibration ensures the temperature displayed on the screen is the actual temperature inside the chamber. Without this, you are firing blind, regardless of what the furnace program says.

Understanding the Trade-offs of Neglect

Ignoring furnace maintenance introduces significant business and clinical risks that go far beyond simple equipment wear.

The Cost of Inconsistent Results

A poorly maintained furnace produces inconsistent results. This leads directly to failed batches, wasted zirconia, lost technician time, and frustrated clinicians who must deal with remakes and rescheduled patient appointments.

The Risk of Catastrophic Failure

Neglecting early warning signs, such as a struggling heating element, can lead to a complete failure mid-cycle. This not only ruins an entire batch of valuable restorations but also results in significant downtime and expensive emergency repairs.

The Hidden Cost of Reduced Lifespan

A sintering furnace is a major capital investment. A consistent maintenance program is the single best way to maximize its operational lifespan and deliver the highest possible return on your investment.

Implementing a Robust Maintenance Protocol

Your maintenance schedule should align with your business's primary goals. Use your manufacturer's guidelines as a baseline for creating your own internal protocol.

- If your primary focus is clinical quality: Prioritize frequent thermocouple calibration and meticulous chamber cleaning to guarantee temperature accuracy and prevent restoration contamination.

- If your primary focus is operational uptime: Emphasize weekly visual inspections of heating elements and insulation to catch potential failures before they happen.

- If your primary focus is long-term cost savings: A comprehensive weekly and monthly check of all components is the best strategy to maximize the furnace's lifespan and avoid costly repairs.

Proactive maintenance transforms your furnace from a potential liability into a reliable asset for clinical excellence.

Summary Table:

| Maintenance Task | Key Benefit |

|---|---|

| Heating Element Inspection | Prevents uneven heating and ensures temperature stability |

| Furnace Chamber Cleaning | Avoids contamination and discoloration of zirconia |

| Insulation Integrity Check | Reduces energy loss and extends component life |

| Gas and Power Line Verification | Enhances safety and operational consistency |

| Sensor and Thermocouple Calibration | Guarantees precise temperature control for accurate sintering |

Ensure your sintering furnace operates at peak performance with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace expertise. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Don't let maintenance issues compromise your results—contact us today to learn how we can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations