Thermal shock resistance is a material's ability to withstand rapid and extreme changes in temperature without cracking or failing. This property is critical in any application where a component is subjected to sudden heating or cooling, as these events create internal stresses that can cause catastrophic failure.

The core issue is not temperature itself, but the rate of temperature change. A material fails when one part of it expands or contracts much faster than another, creating internal stress that exceeds its structural limits.

How Thermal Shock Causes Failure

To prevent thermal shock, it is essential to first understand the physical mechanism that leads to material failure. It is a battle between thermal expansion and the material's inherent strength.

The Core Mechanism: Uneven Expansion

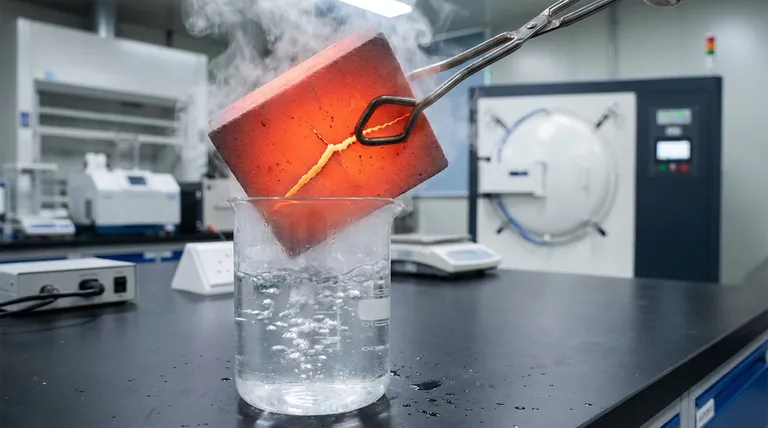

When a material is heated, it expands. When it is cooled, it contracts. If this temperature change happens very quickly, the surface of the material will change temperature (and size) long before its core does.

Imagine pouring ice-cold water into a hot glass baking dish. The inner surface cools and contracts instantly, while the hotter outer glass remains expanded.

Internal Stress Build-up

This difference in expansion or contraction between the surface and the core creates immense internal tension and compression. The contracting surface is essentially trying to pull away from the still-expanded core, creating mechanical stress.

Exceeding Material Strength

Every material has a finite strength. When the internal stress generated by the rapid temperature change exceeds the material's tensile or flexural strength, a crack initiates to relieve that stress. This is a thermal shock failure.

Key Factors in Thermal Shock Resistance

A material's resistance to thermal shock is not a single property but a combination of several independent physical characteristics. Understanding these factors is key to material selection.

Low Coefficient of Thermal Expansion (CTE)

This is arguably the most important factor. Materials with a low CTE simply expand and contract less when their temperature changes. Less change in size means less internal stress is generated, making them inherently more resistant to thermal shock.

High Thermal Conductivity

A material with high thermal conductivity allows heat to travel through it quickly. This helps the entire object maintain a more uniform temperature, even during rapid heating or cooling, which minimizes the temperature difference between the surface and the core and thus reduces stress.

High Mechanical Strength

A stronger material can simply endure higher levels of internal stress before it fractures. High tensile and flexural strength provide a greater safety margin against the stresses induced by thermal gradients.

High Elasticity (Low Modulus of Elasticity)

A material with a lower modulus of elasticity is more "flexible." It can deform elastically to accommodate some internal stress without fracturing, behaving more like rubber than a brittle glass.

Understanding the Trade-offs

There is no single "perfect" material, and optimizing for thermal shock resistance often involves compromising on other desirable properties.

Material Property Conflicts

Materials with excellent thermal shock resistance, like certain technical ceramics, may have poor impact resistance or be difficult to machine. Conversely, a strong metal alloy might have a high CTE, making it vulnerable to thermal cycling fatigue over time.

The Role of Geometry

Thermal shock failure is not just about the material; it's also about the part's design. Thick sections create larger thermal gradients than thin sections. Sharp internal corners act as stress concentrators, providing a natural starting point for a crack to form. A good design with smooth radii and uniform thickness can dramatically improve a component's life.

Making the Right Choice for Your Application

Your selection strategy must be guided by the specific demands of your environment. There is no one-size-fits-all solution.

- If your primary focus is surviving extreme, rapid temperature swings: Prioritize materials with a very low Coefficient of Thermal Expansion (CTE) and high thermal conductivity, like fused silica or silicon nitride.

- If your application involves both thermal cycling and high mechanical loads: You must balance thermal shock resistance with the required tensile strength, often looking at specialized superalloys or ceramic matrix composites.

- If you are limited to a specific material: Focus on controlling the process by reducing the rate of heating and cooling, or on redesigning the component to eliminate sharp corners and thick cross-sections.

Understanding these principles moves you from simply selecting a material to engineering a truly reliable solution.

Summary Table:

| Key Factor | Description | Importance |

|---|---|---|

| Low Coefficient of Thermal Expansion (CTE) | Material expands/contracts less with temperature changes | Reduces internal stress from thermal gradients |

| High Thermal Conductivity | Heat transfers quickly through material | Minimizes temperature differences between surface and core |

| High Mechanical Strength | Material withstands high stress before fracturing | Provides safety margin against thermal-induced stresses |

| High Elasticity (Low Modulus) | Material deforms elastically under stress | Absorbs stress without cracking, enhancing flexibility |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing thermal shock resistance testing and material durability. Contact us today to discuss how our tailored solutions can optimize your processes and drive innovation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing