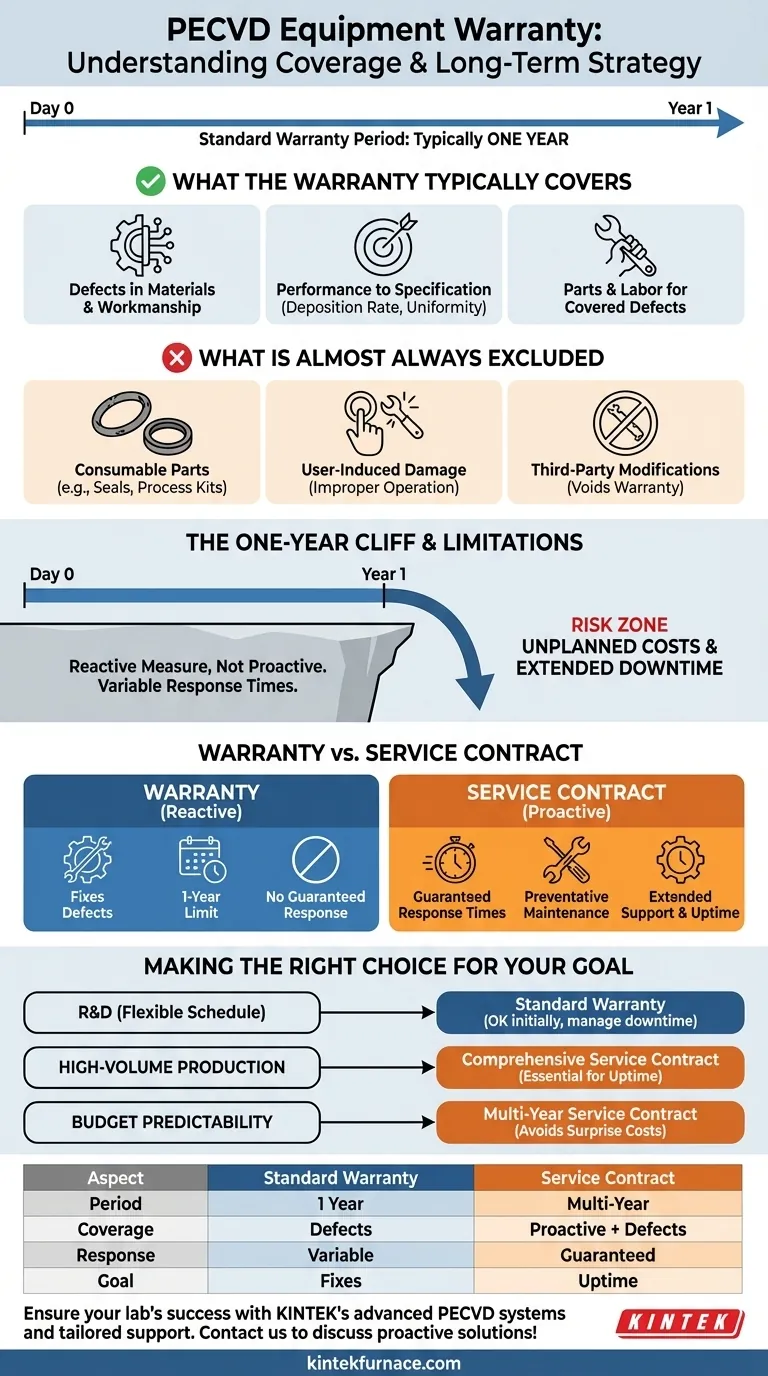

The standard warranty period for new PECVD equipment is typically one year. This period begins from the date of final acceptance at your facility and generally covers defects in materials and workmanship, ensuring the system performs to its specified capabilities under normal operating conditions.

The one-year warranty is a baseline industry standard. However, the true value lies in understanding what is—and what is not—covered, and how to plan for long-term operational reliability beyond this initial period.

The Scope of a Standard PECVD Warranty

A manufacturer's warranty is a commitment to the quality and performance of their equipment. For a complex system like a Plasma-Enhanced Chemical Vapor Deposition (PECVD) tool, this guarantee is a critical part of your initial investment.

What the Warranty Typically Covers

Defects in Materials and Workmanship: This is the core of any warranty. It protects you from manufacturing flaws in the system's components, from the vacuum chamber to the RF generator.

Performance to Specification: The equipment is guaranteed to meet the performance metrics agreed upon during purchase, such as deposition rate and film uniformity, for the duration of the warranty.

Parts and Labor: If a covered component fails due to a defect, the manufacturer will typically provide the replacement part and the labor required for the repair at no charge.

What Is Almost Always Excluded

Consumable Parts: Items that are expected to be consumed or wear out during normal operation are not covered. This includes items like O-rings, specific seals, and process kit components that see direct plasma exposure.

User-Induced Damage: Any damage caused by improper operation, failure to follow maintenance procedures, or using the machine outside of its specified process window will void the warranty for that repair.

Third-Party Modifications: Unauthorized modifications or additions to the equipment will typically void the warranty, as the manufacturer can no longer guarantee the system's integrity.

Understanding the Trade-offs: Warranty vs. Service Contract

Relying solely on the initial warranty period can be a significant risk for a mission-critical tool. The warranty is a reactive measure for defects, not a proactive plan for uptime.

Limitation 1: The One-Year Cliff

The most obvious limitation is the one-year duration. Complex deposition systems can and do experience issues after the first year. Without a plan, you become fully responsible for all repair costs, which can be substantial.

Limitation 2: Response Time Variables

While parts and labor may be covered, the warranty may not guarantee a specific response time. Depending on technician availability and part logistics, your critical equipment could be down for an extended period.

The Role of a Service Contract

This is where a service contract becomes essential. A service contract is a separate agreement that extends beyond the warranty to provide ongoing support. It often includes guaranteed response times, preventative maintenance visits, and discounts on parts and labor. It is a tool for managing risk and ensuring operational continuity.

Making the Right Choice for Your Goal

The initial warranty is a starting point, not the final destination. Your strategy should be based on your operational needs and risk tolerance.

- If your primary focus is R&D with a flexible schedule: The standard one-year warranty may be sufficient initially, as intermittent downtime may be manageable.

- If your primary focus is high-volume manufacturing or production: You must secure a comprehensive service contract before the initial warranty expires to guarantee uptime and predictable maintenance costs.

- If your primary focus is budget predictability: A multi-year service contract that includes preventative maintenance and consumables forecasting is the most effective way to avoid unexpected, high-cost repairs.

Ultimately, viewing the warranty as the first step in a long-term equipment lifecycle management strategy will ensure your investment remains productive for years to come.

Summary Table:

| Aspect | Details |

|---|---|

| Standard Warranty Period | 1 year from final acceptance |

| Coverage | Defects in materials/workmanship, performance to spec, parts and labor |

| Exclusions | Consumables, user-induced damage, third-party modifications |

| Key Limitation | Reactive support; no guaranteed response times |

| Recommended Strategy | Service contracts for proactive maintenance and uptime |

Ensure your lab's success with KINTEK's advanced PECVD systems and tailored support. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace solutions like CVD/PECVD Systems, backed by deep customization to meet your unique needs. Contact us today to discuss how our reliable equipment and service contracts can enhance your operational efficiency and minimize downtime!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process