Precise temperature control is the defining factor that separates a simple vacuum oven from a high-performance material processing tool. In a vacuum furnace, this precision ensures that heat is applied accurately and uniformly, allowing for the creation of materials with specific, repeatable properties. This control is essential for executing customized thermal profiles tailored to the unique requirements of advanced materials and complex components.

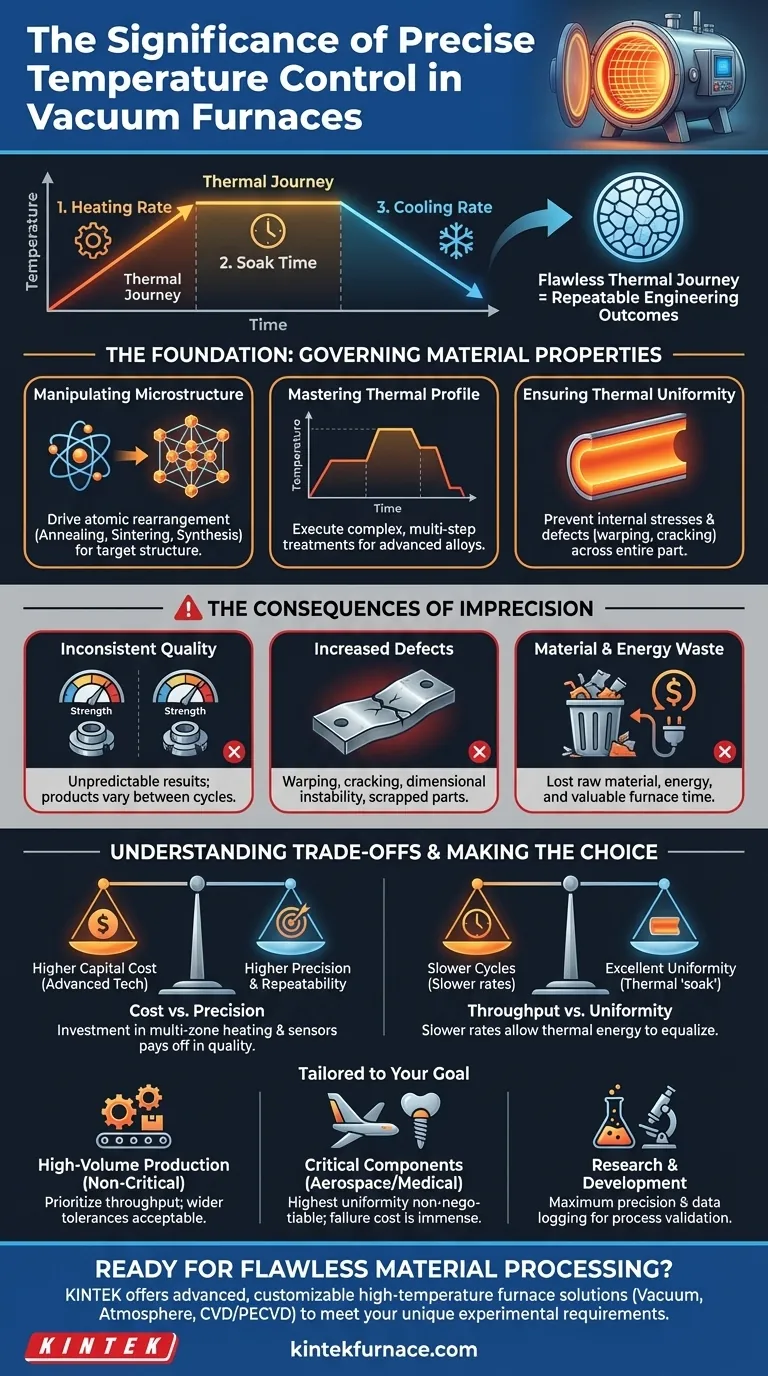

At its core, the significance of temperature control goes beyond simply hitting a setpoint. It is about flawlessly managing the entire thermal journey—heating rate, soak duration, and cooling—to deliberately manipulate a material's internal structure and achieve desired engineering outcomes without introducing defects.

The Foundation: How Temperature Governs Material Properties

Precise temperature control isn't a feature; it's the fundamental mechanism for achieving results. The vacuum environment removes chemical variables like oxidation, making the thermal process the sole driver of change.

Manipulating the Microstructure

Heat provides the energy for a material's atoms to move and rearrange. Processes like annealing (softening), sintering (fusing particles), and synthesis (forming new compounds) all depend on holding a material at a specific temperature for a specific time to achieve a target microstructure.

Even small deviations can result in an incomplete or incorrect atomic rearrangement, fundamentally altering the material's final properties like hardness, strength, or conductivity.

The Importance of the Thermal Profile

The peak temperature is only one part of the equation. The entire thermal profile, or cycle, is critical. This includes:

- Heating Rate: How quickly the material reaches temperature.

- Soak Time: How long it is held at the target temperature.

- Cooling Rate: How quickly it returns to ambient temperature.

Precise control over these three stages allows operators to execute complex, multi-step treatments required for advanced alloys and composites.

Ensuring Thermal Uniformity

Precise control also means ensuring the temperature is the same across the entire part. A significant temperature difference between the core and the surface of a component can create internal stresses, leading to failure.

The Consequences of Imprecision

When temperature control is poor, the results are unpredictable and costly. The process becomes a game of chance rather than a repeatable engineering operation.

Inconsistent Product Quality

If the furnace temperature fluctuates between cycles, the final product will be inconsistent. A part produced on Monday will have different mechanical properties from one produced on Tuesday, even if the "recipe" was the same. This lack of repeatability is unacceptable for critical applications.

Increased Risk of Defects

Poor temperature uniformity is a primary cause of defects. If one section of a part heats or cools faster than another, the resulting internal stress can cause warping, cracking, or dimensional instability. This leads directly to scrapped parts.

Material and Energy Waste

Every failed or inconsistent part represents wasted raw material, energy, and valuable furnace time. The cost of imprecision is measured in scrapped components, lost production hours, and compromised product reliability.

Understanding the Trade-offs

Achieving perfect temperature control involves balancing competing factors. Understanding these trade-offs is key to specifying and operating a furnace effectively.

Cost vs. Precision

Higher precision demands more sophisticated equipment. This includes multi-zone heating elements, more accurate sensors (thermocouples), and advanced programmable logic controllers (PLCs). This investment increases the furnace's capital cost but pays off in quality and repeatability.

Throughput vs. Uniformity

Achieving excellent temperature uniformity often requires slower heating and cooling rates to allow thermal energy to fully "soak" through the workload. This can reduce the number of cycles you can run per day, impacting overall throughput.

Sensor Data vs. True Part Temperature

A controller is only as good as the data it receives. It's critical to recognize that a sensor measures the temperature at its specific location, which may not be the true temperature of the parts. Proper sensor placement and calibration are essential for the control system to be effective.

Making the Right Choice for Your Goal

The required level of precision depends entirely on your application and objective.

- If your primary focus is high-volume production of non-critical parts: You may prioritize throughput, accepting slightly wider temperature tolerances if they do not compromise the component's basic function.

- If your primary focus is processing critical, high-value components (e.g., aerospace, medical): The highest level of temperature uniformity and control is non-negotiable, as the cost of a single part failure is immense.

- If your primary focus is research and development: Maximum precision and data logging are essential to ensure process repeatability, validate new material properties, and publish accurate findings.

Ultimately, mastering temperature control transforms a vacuum furnace from a simple heat source into a precision instrument for engineering materials.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Microstructure Control | Enables processes like annealing and sintering for desired material properties. |

| Thermal Profile | Critical for heating rate, soak time, and cooling rate to avoid defects. |

| Uniformity | Prevents internal stresses, warping, and cracking in components. |

| Consequences of Imprecision | Leads to inconsistent quality, defects, and wasted resources. |

| Application Focus | High precision for critical parts; balanced for high-volume production. |

Ready to achieve flawless material processing with precise temperature control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, Muffle, Tube, and Rotary Furnaces, as well as CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering reliable, repeatable results for critical applications in aerospace, medical, and R&D. Contact us today to discuss how our tailored furnace solutions can elevate your lab's performance and efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity