At its core, the rotary kiln is the central piece of industrial technology for producing lime. It accomplishes this through a high-temperature process called calcination, which chemically transforms limestone (calcium carbonate) into quicklime (calcium oxide) by driving off carbon dioxide. This process is fundamental to supplying essential materials for steelmaking, construction, and numerous chemical applications.

The rotary kiln is not just a furnace; it is a continuously operating chemical reactor. Its primary role is to provide a controlled, high-temperature environment that efficiently and consistently produces high-quality quicklime on an industrial scale.

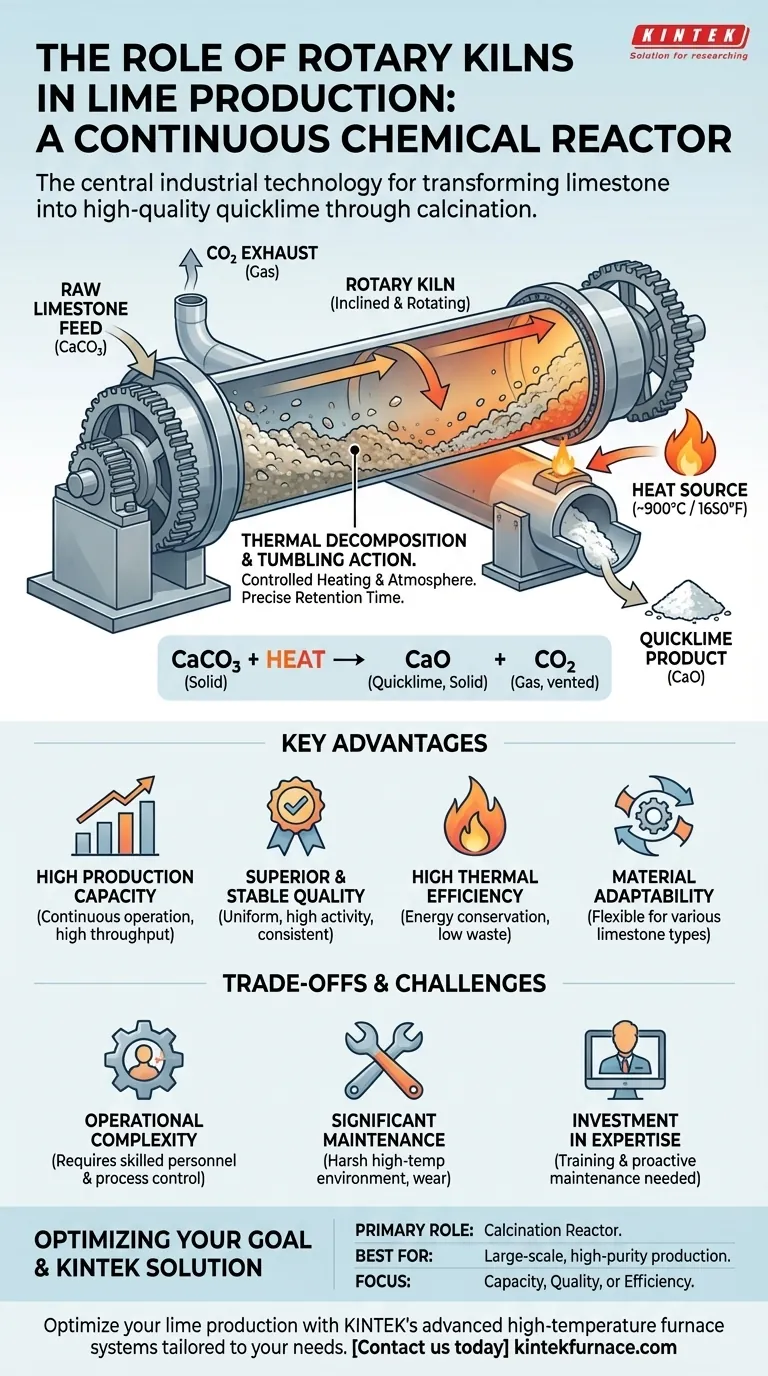

How a Rotary Kiln Produces Lime

A rotary kiln executes a precise thermal and mechanical process to convert raw limestone into a finished product. The entire operation is designed for continuous, high-volume output.

The Fundamental Chemical Reaction

The process is based on thermal decomposition. When limestone (CaCO₃) is heated to temperatures around 900°C (1650°F) or higher, it breaks down.

This reaction releases carbon dioxide (CO₂) gas, leaving behind the desired solid product: quicklime (CaO).

The Mechanical Process

A rotary kiln is a large, rotating cylindrical vessel mounted at a slight incline. Raw limestone is fed into the upper end.

As the kiln slowly rotates, the material tumbles and gradually moves down toward the lower, hotter end. This tumbling action ensures every particle is evenly exposed to the high heat.

Controlled Heating and Atmosphere

Heat is typically applied directly by a flame inside the kiln. The controlled temperature profile and the sealed environment ensure the calcination reaction proceeds efficiently.

The material remains inside the kiln for a specific duration, known as the retention time, which is critical for ensuring the conversion is complete.

Key Advantages in Lime Production

Rotary kilns are the industry standard for large-scale lime production due to a combination of distinct advantages that are difficult to achieve with other technologies.

High Production Capacity

Rotary kilns are designed for continuous operation and high throughput. Their ability to process large volumes of limestone makes them ideal for industrial applications that demand a constant supply of lime.

Superior and Stable Product Quality

The precise control over temperature and the constant tumbling of material result in a highly uniform and consistent product. This produces lime with high activity, a crucial quality metric for its end-use in steel and chemical manufacturing.

High Thermal Efficiency

Modern rotary kilns are engineered for energy conservation. Their design maximizes heat transfer to the material, minimizing wasted energy and reducing operational costs.

Adaptability to Raw Materials

These kilns can process a wide range of limestone types and sizes. This flexibility allows producers to use locally available raw materials without compromising the quality of the final product.

Understanding the Trade-offs and Challenges

While highly effective, operating a rotary kiln system is a significant undertaking that comes with specific demands and complexities.

Operational Complexity

Properly running a rotary kiln requires skilled technical personnel. Factors like feed rate, rotational speed, fuel flow, and temperature must be carefully managed to maintain process stability and product quality.

Significant Maintenance Requirements

The harsh, high-temperature environment means that equipment is subject to significant wear. Delayed or improper maintenance can lead to equipment failure, costly downtime, and potential production accidents.

Investment in Expertise

To ensure safe and efficient operation, facilities must invest in technical training for operators and robust maintenance management programs. This enhances operator skill and ensures the long-term stability and reliability of the equipment.

Making the Right Choice for Your Goal

Optimizing a rotary kiln operation depends entirely on your primary objective. Understanding the balance between capacity, quality, and operational cost is essential.

- If your primary focus is large-scale, continuous production: The rotary kiln is the definitive technology due to its unmatched throughput and capacity.

- If your primary focus is high-purity, consistent product quality: The kiln's precise control over temperature and mixing provides superior control over lime activity and consistency.

- If your primary focus is operational efficiency and reliability: You must commit to investing heavily in operator training and a proactive maintenance schedule to maximize uptime and energy efficiency.

Ultimately, the rotary kiln's ability to transform a raw mineral into a high-value industrial chemical with precision and scale makes it an indispensable asset in modern manufacturing.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Role | Central chemical reactor for calcination, converting limestone to quicklime |

| Key Process | Thermal decomposition at ~900°C, with controlled heating and tumbling action |

| Main Advantages | High production capacity, superior product quality, high thermal efficiency, material adaptability |

| Challenges | Operational complexity, significant maintenance, need for skilled personnel |

| Best For | Large-scale, continuous production; high-purity lime; industries like steelmaking and construction |

Optimize your lime production with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories and industrial facilities with high-temperature furnace systems tailored to your needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet unique experimental and production requirements. Contact us today to enhance efficiency, quality, and reliability in your operations!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control