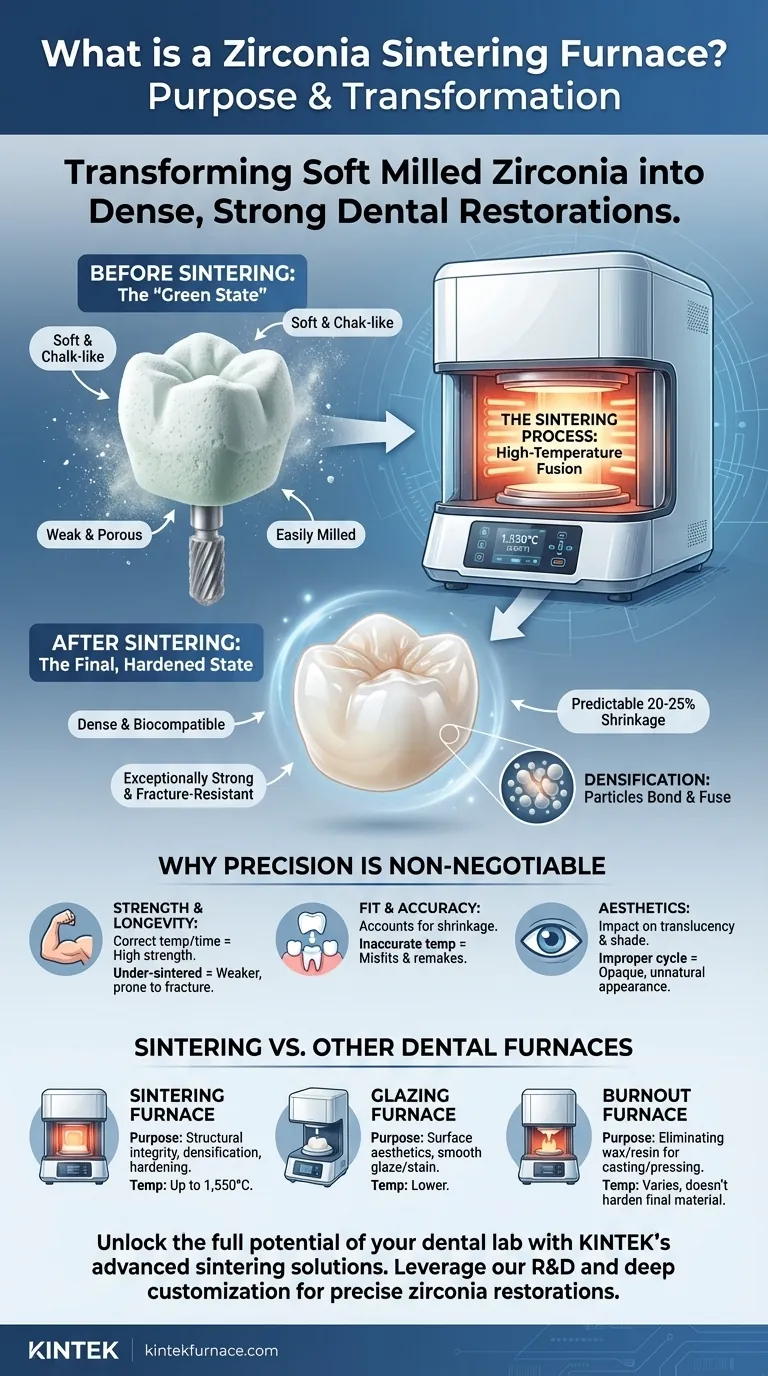

In short, the purpose of a zirconia sintering furnace is to transform a soft, chalk-like milled zirconia restoration into its final, dense, and exceptionally strong state. This is accomplished through a precise, high-temperature heating process that fuses the material's particles, giving the restoration the durability required to function in the mouth.

The core problem is that zirconia cannot be milled in its final, super-hard form. The sintering furnace is the essential bridge, converting the easily-milled "green state" material into a permanent, biocompatible restoration with the strength to withstand immense oral forces.

From Chalk to Ceramic: The Sintering Transformation

A sintering furnace is not just an oven; it is a precision instrument that fundamentally alters the physical properties of zirconia. Understanding this transformation is key to appreciating its role.

The "Green State" Material

Zirconia restorations are first milled from a block of pre-sintered material. This is often called the "green state" or "white state."

In this form, the zirconia has a soft, chalk-like consistency. This is intentional, as it allows for rapid and accurate milling with minimal wear on the milling burs. However, at this stage, the material is far too weak and porous for clinical use.

The Sintering Process

Once milling is complete, the restoration is placed in the sintering furnace. The furnace executes a highly specific heating program.

During this cycle, the temperature is raised to as high as 1,550°C (2,822°F). This intense heat causes the individual zirconia particles to bond and fuse together, a process called densification.

This fusion eliminates the porosity present in the green state material and causes the restoration to shrink by a predictable amount, typically 20-25%.

The Final, Hardened State

After the heating and controlled cooling cycle, the zirconia emerges in its final, fully sintered form. It is now one of the strongest and most fracture-resistant materials used in dentistry.

This sintered restoration is now dense, biocompatible, and ready for final staining, glazing, or polishing before being delivered to the patient.

Why Precision is Non-Negotiable

The success of a zirconia restoration is directly tied to the accuracy of the sintering furnace. Deviations from the prescribed protocol can compromise the entire case.

Impact on Strength and Longevity

The final strength of the zirconia is developed during sintering. An incorrect temperature or an insufficient hold time will result in an under-sintered restoration that is weaker and more prone to fracture.

Impact on Fit and Accuracy

CAD/CAM software accounts for the 20-25% shrinkage during the design phase by oversizing the initial restoration.

If the furnace's temperature is inaccurate, the restoration may shrink too much or too little, resulting in a crown or bridge that does not fit. This is one of the most common reasons for remakes.

Impact on Aesthetics

The sintering protocol, particularly the heating and cooling rates, also influences the material's optical properties. An improper cycle can negatively affect the final translucency of the restoration, making it appear too opaque and less natural.

Sintering vs. Other Dental Furnaces

It's crucial to distinguish a sintering furnace from other furnaces used in a dental lab, as they serve entirely different purposes.

Sintering vs. Glazing/Ceramic Furnaces

A glazing furnace (or porcelain furnace) operates at much lower temperatures. It is used to fire a thin layer of glass-like glaze or stain onto the surface of a restoration to give it a smooth, natural-looking finish. Sintering is for structural integrity; glazing is for surface aesthetics.

Sintering vs. Burnout Furnaces

A burnout furnace is used in the lost-wax technique for casting metal or pressing ceramics. Its job is to melt and eliminate a wax or resin pattern, leaving behind a hollow mold into which another material is cast or pressed. It does not harden the final material itself.

Making the Right Choice for Your Goal

Understanding the purpose of sintering allows you to control the outcome of your zirconia restorations based on your clinical or business objectives.

- If your primary focus is maximum strength and longevity: Adhere strictly to the zirconia manufacturer's recommended conventional (long) sintering cycles.

- If your primary focus is same-day, in-office dentistry: You must use a furnace with validated "speed" sintering cycles and only use zirconia materials that are specifically approved for these faster protocols.

- If your primary focus is achieving optimal aesthetics: Pay close attention to the entire sintering program, as both temperature and cooling rates can impact the final translucency and shade.

Mastering the sintering process is fundamental to unlocking the full potential of zirconia and delivering predictable, high-quality dental restorations.

Summary Table:

| Aspect | Details |

|---|---|

| Purpose | Transforms soft, milled zirconia into dense, strong dental restorations via high-temperature sintering. |

| Key Process | Heating to ~1,550°C causes particle fusion, eliminating porosity and enabling 20-25% shrinkage. |

| Benefits | Ensures high strength, accurate fit, biocompatibility, and improved aesthetics for long-lasting results. |

| Importance | Precision is critical; deviations can weaken the restoration, cause misfits, or affect translucency. |

Unlock the full potential of your dental lab with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces tailored for dental applications, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise sintering cycles for zirconia restorations, enhancing strength, fit, and aesthetics. Ready to elevate your dental restorations? Contact us today to discuss your needs and discover how our expertise can drive your success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns