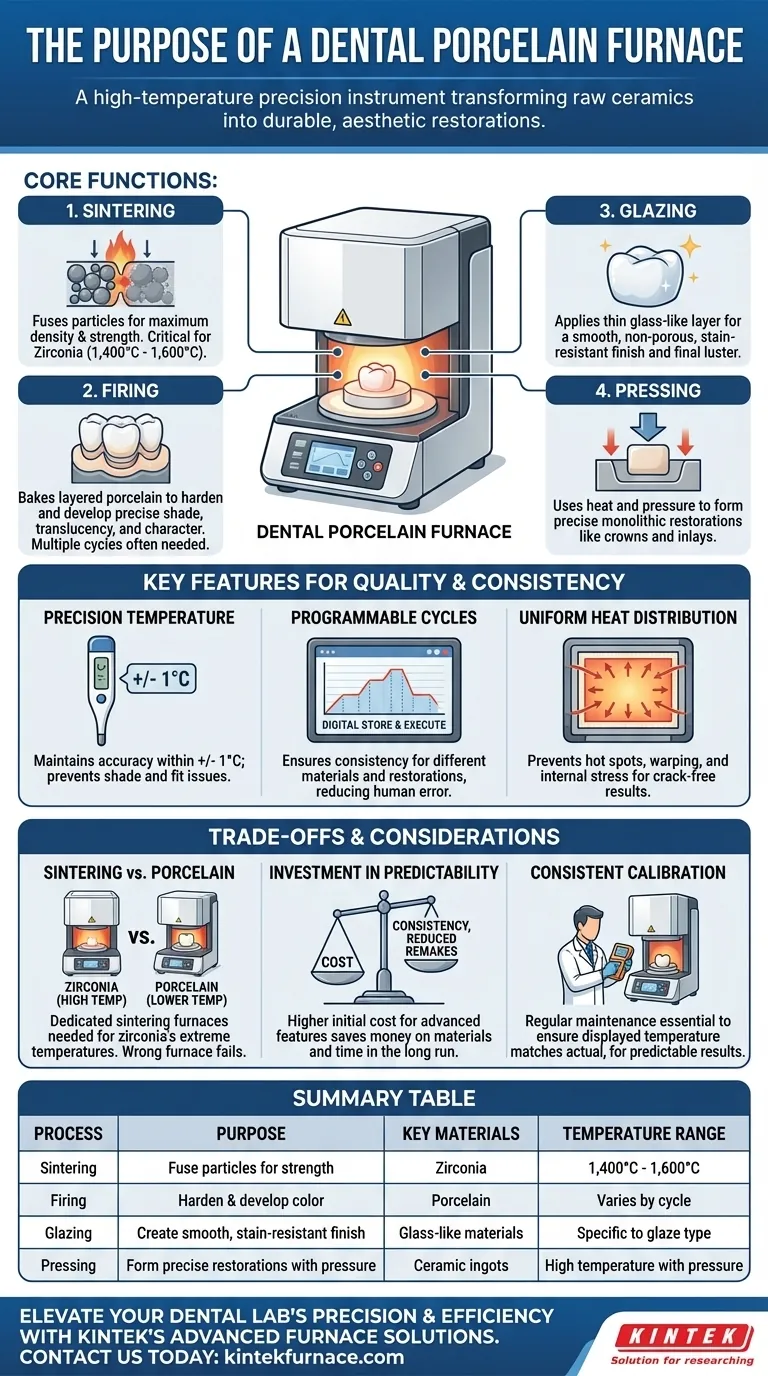

At its core, a dental porcelain furnace is a high-temperature oven used in dental laboratories to fire, sinter, and process ceramic materials. Its purpose is to transform raw porcelain or zirconia powders into strong, durable, and aesthetically pleasing dental restorations like crowns, bridges, and veneers.

A dental furnace is not simply a heat source; it is a precision instrument that meticulously controls temperature and atmosphere. This control is what allows technicians to convert raw ceramic materials into final restorations that possess the required strength, fit, and lifelike appearance.

From Powder to Prosthesis: The Furnace's Core Functions

A modern dental laboratory relies on the furnace to execute several distinct thermal processes. Each one is critical for achieving a successful, long-lasting restoration.

The Sintering Process for Maximum Strength

Sintering is the process of heating a compacted material to a high temperature, just below its melting point, to fuse the particles together. This dramatically increases the material's density and strength.

Sintering is especially critical for high-strength ceramics like zirconia, which require temperatures between 1,400°C and 1,600°C to achieve their final, robust state suitable for bridges and implants.

Firing for Hardness and Color

For traditional porcelain, the furnace performs a firing cycle. This bakes the layered porcelain, hardening it and developing its precise shade, translucency, and character.

Multiple firings are often necessary as the technician builds up layers of porcelain to mimic the complex look of a natural tooth.

Glazing for a Natural Finish

The final step is often glazing. A thin layer of glass-like material is applied and fired at a specific temperature.

This creates a smooth, non-porous, and stain-resistant surface that gives the restoration its final luster and protects it from wear.

Pressing for Precise Forms

Some furnaces, known as press furnaces, use heat and pressure to force a heated ceramic ingot into a mold. This method is used to create incredibly precise and strong monolithic restorations like crowns and inlays.

Key Features That Ensure Quality and Consistency

The difference between a mediocre restoration and a perfect one often comes down to the quality of the furnace. Certain features are non-negotiable for achieving predictable, high-quality results.

Unwavering Temperature Precision

Modern furnaces maintain temperature accuracy within +/- 1 degree Celsius. This precision is vital because slight temperature deviations can ruin the shade, fit, or strength of the ceramic.

Programmable Firing Cycles

Technicians must use different firing programs for different materials and restoration types. The ability to create, store, and execute these complex multi-stage cycles digitally ensures consistency and reduces human error.

Uniform Heat Distribution

An advanced muffle, or heating chamber, is designed to provide uniform heat from all sides. This prevents hot spots that can cause warping or internal stresses within the restoration, leading to fractures.

Understanding the Trade-offs and Considerations

While essential, not all furnaces are created equal. Understanding their differences is key to making an informed investment and workflow decision.

Sintering vs. Conventional Porcelain Furnaces

A furnace designed for traditional porcelain typically does not reach the extreme temperatures needed for sintering zirconia. Labs working with high-strength zirconia must invest in a dedicated sintering furnace.

Attempting to use the wrong type of furnace will result in a failed restoration, wasting significant time and material.

The Investment in Predictability

Higher-end furnaces with superior temperature control and more programmable features come at a premium. However, this initial cost is an investment in consistency and reduced remakes.

A reliable furnace minimizes failed cycles, saving the lab money on materials and technician time in the long run.

The Need for Consistent Calibration

A furnace is a precision instrument that requires regular maintenance. Calibration is essential to ensure the temperature displayed on the screen matches the actual temperature inside the chamber, guaranteeing predictable results over the life of the machine.

How to Apply This to Your Laboratory's Goal

Choosing the right furnace depends entirely on the type of restorations your lab produces.

- If your primary focus is high-strength zirconia frameworks: You must invest in a dedicated high-temperature sintering furnace capable of reaching 1,600°C.

- If your primary focus is highly aesthetic layered porcelain veneers: Prioritize a furnace with exceptional low-temperature control and precise programming for glazing and correction cycles.

- If your primary focus is efficiency and high volume: Features like program storage, rapid heating/cooling cycles, and multi-unit capacity are your most important considerations.

Ultimately, the dental porcelain furnace is the instrument that brings the technician's artistry and the material's potential to life.

Summary Table:

| Process | Purpose | Key Materials | Temperature Range |

|---|---|---|---|

| Sintering | Fuse particles for strength | Zirconia | 1,400°C - 1,600°C |

| Firing | Harden and develop color | Porcelain | Varies by cycle |

| Glazing | Create smooth, stain-resistant finish | Glass-like materials | Specific to glaze type |

| Pressing | Form precise restorations with pressure | Ceramic ingots | High temperature with pressure |

Elevate your dental lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a range of high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure a perfect fit for your unique needs, whether you're sintering zirconia, firing porcelain, or pressing ceramics. Contact us today to discuss how our reliable, high-performance furnaces can reduce remakes, save time, and deliver superior dental restorations consistently.

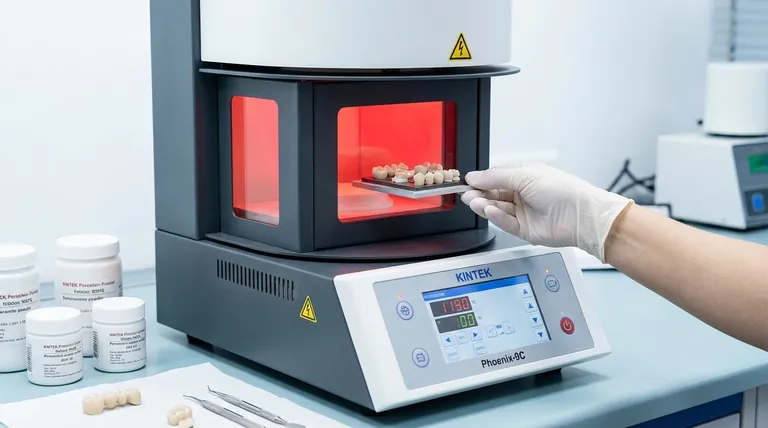

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations