In Plasma-Enhanced Chemical Vapor Deposition (PECVD), a glow discharge is an ionized gas, or plasma, that serves as the engine for the entire process. It is created by applying a high-frequency electric field to reactant gases under low pressure. This plasma generates highly reactive chemical species that can form a thin film on a substrate at significantly lower temperatures than traditional deposition methods.

The core function of glow discharge is not simply to heat the chamber, but to use electrical energy to break down stable gas molecules into reactive fragments. These fragments then have enough energy to build a thin film without requiring the high thermal energy of conventional methods.

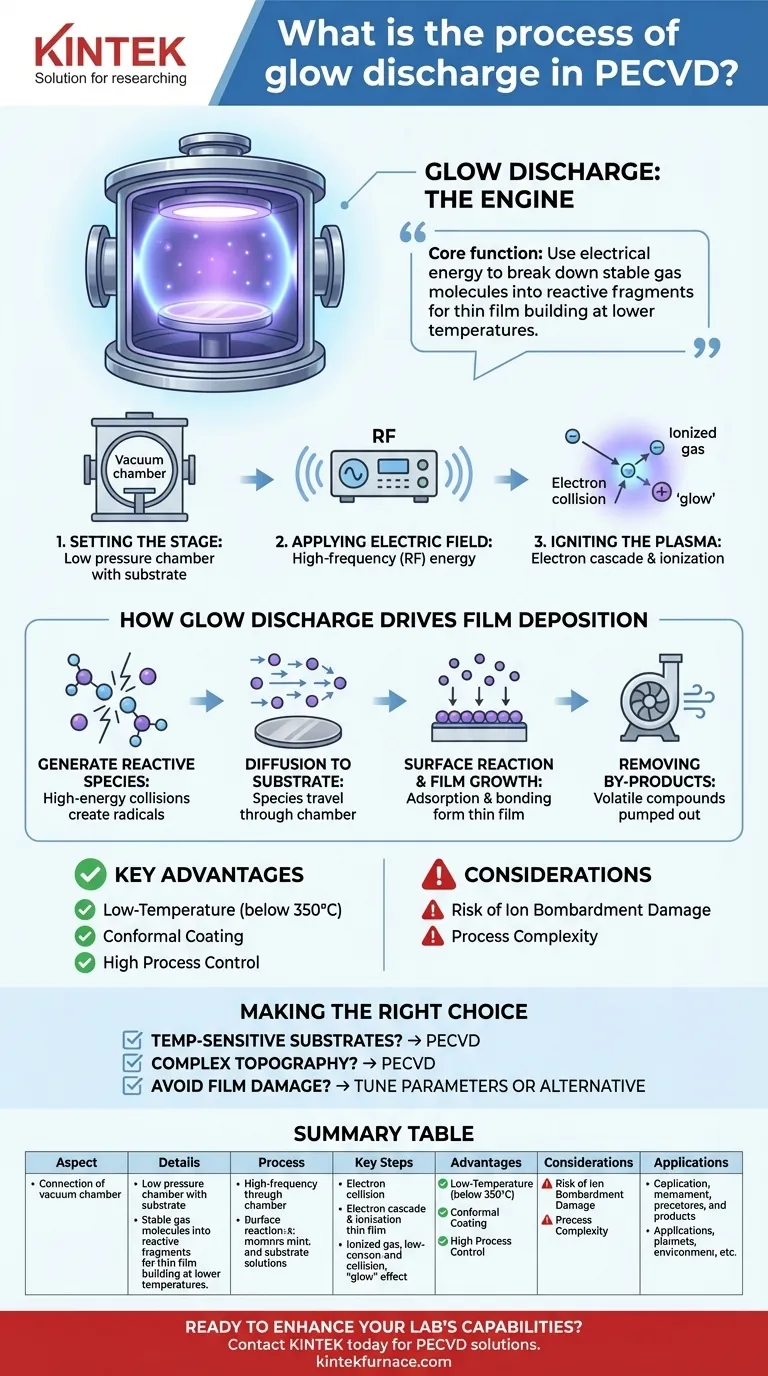

The Mechanism: From Inert Gas to Active Plasma

To truly understand glow discharge, we must visualize it as a controlled, self-sustaining chain reaction happening at the molecular level.

Step 1: Setting the Stage

The process begins by introducing specific reactant gases into a vacuum chamber, which is held at a very low pressure. A substrate, such as a silicon wafer, is placed inside.

Step 2: Applying the Electric Field

A high-frequency electric field (typically radio frequency, or RF) is applied between two electrodes within the chamber. This field is the critical source of energy.

Step 3: Igniting the Plasma

The electric field accelerates the few free electrons that are naturally present in the gas. As these energized electrons collide with neutral gas molecules, they knock loose more electrons.

This event creates a cascade: each new electron is also accelerated by the field, leading to more collisions and freeing even more electrons. This rapid ionization process, where the gas becomes a mixture of ions, electrons, and neutral particles, is the glow discharge plasma.

How Glow Discharge Drives Film Deposition

Once the plasma is stable, it becomes the environment where the chemistry of deposition occurs. The "glow" is the visible evidence of this high-energy state.

Generating Reactive Species

The high-energy electron collisions do more than just create ions; they also break the chemical bonds of the reactant gas molecules. This creates highly reactive radicals, which are neutral fragments with unpaired electrons.

These radicals are the true workhorses of PECVD. They are chemically primed to react and form new bonds, which is essential for building the film.

Diffusion to the Substrate

The newly formed ions and radicals are not confined. They diffuse throughout the chamber and travel toward the substrate surface.

Surface Reaction and Film Growth

When these reactive species reach the substrate, they adsorb onto its surface. Here, they undergo a series of chemical reactions, bonding with each other and the surface to form a stable, solid thin film.

Removing By-products

Any volatile chemical by-products from these surface reactions are pumped out of the chamber by the vacuum system, ensuring a pure film is left behind.

Key Advantages and Considerations

The use of a glow discharge plasma is what separates PECVD from other methods and defines its unique advantages and challenges.

The Low-Temperature Advantage

Because the electric field provides the energy to create reactive species, the substrate itself does not need to be heated to extreme temperatures. This allows for deposition on temperature-sensitive materials like plastics or pre-processed semiconductor wafers.

The Risk of Ion Bombardment

While the plasma is essential, the ions within it can be accelerated by the electric field and physically strike the substrate. This ion bombardment can sometimes cause damage or introduce stress into the growing film.

Process Control and Complexity

Glow discharge PECVD offers many variables to control film properties—such as power, pressure, and gas flow. This provides excellent flexibility but also adds a layer of complexity to process optimization compared to simpler thermal methods.

Making the Right Choice for Your Goal

Understanding the glow discharge mechanism helps you decide when PECVD is the appropriate tool for your deposition needs.

- If your primary focus is depositing on temperature-sensitive substrates: PECVD is an ideal choice, as the glow discharge enables high-quality film growth below 350°C.

- If your primary focus is achieving dense, conformal films over complex topography: PECVD is highly effective because the reactive plasma species can reach and coat intricate structures.

- If your primary focus is avoiding film damage or achieving perfect crystal quality: You must carefully tune the plasma parameters to minimize ion bombardment, or consider alternative high-temperature methods like traditional CVD for specific applications.

Mastering the glow discharge process is fundamental to leveraging the full potential of plasma-enhanced deposition.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Glow discharge in PECVD uses a high-frequency electric field to create plasma from reactant gases under low pressure, generating reactive species for thin film deposition. |

| Key Steps | 1. Introduce gases in vacuum chamber. 2. Apply RF electric field. 3. Ignite plasma via electron collisions. 4. Generate reactive radicals. 5. Species diffuse to substrate. 6. Surface reactions form film. 7. Remove by-products. |

| Advantages | Low-temperature operation (below 350°C), suitable for sensitive materials; conformal coating on complex structures; high process control via power, pressure, and gas flow. |

| Considerations | Risk of ion bombardment causing film damage; requires careful optimization of plasma parameters; more complex than thermal methods. |

| Applications | Ideal for temperature-sensitive substrates like plastics and semiconductors; effective for dense, uniform films in electronics, optics, and coatings. |

Ready to enhance your lab's capabilities with advanced PECVD systems? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization to meet your unique experimental needs. Whether you're working with temperature-sensitive materials or require precise film deposition, our expertise ensures optimal performance and efficiency. Contact us today to discuss how we can help you achieve superior results in your research and development!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures