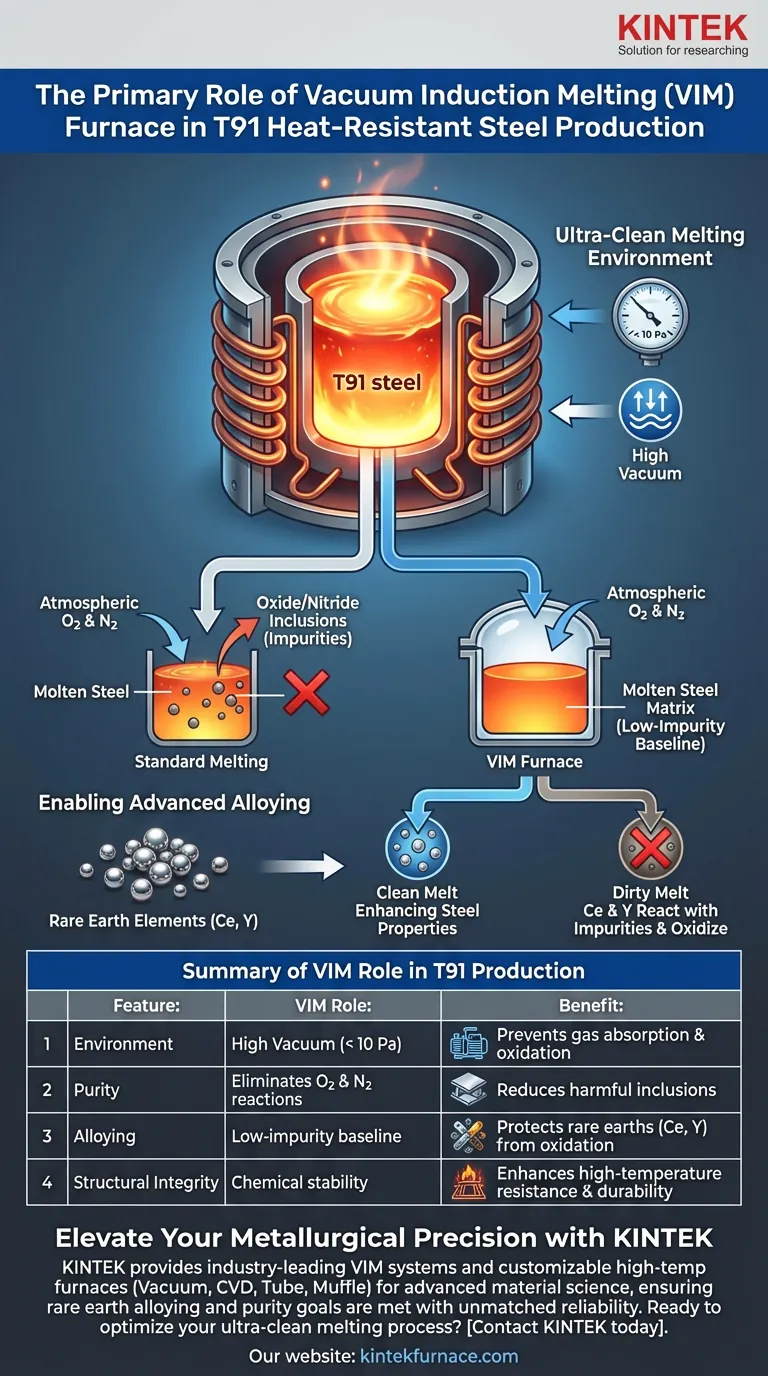

The primary role of a Vacuum Induction Melting (VIM) furnace is to create an ultra-clean melting environment that is critical for the integrity of T91 heat-resistant steel. By operating under high vacuum conditions of less than 10 Pa, the furnace effectively eliminates the interaction between molten steel and atmospheric oxygen or nitrogen. This isolation provides the low-impurity foundation necessary for precise alloying.

By effectively removing atmospheric contaminants, the VIM furnace serves as the prerequisite step for adding sensitive rare earth elements, ensuring they enhance the steel's properties rather than reacting with impurities.

The Mechanics of Purity

To understand why VIM is essential for T91 steel, one must look beyond simple melting and understand the chemical environment required for high-performance alloys.

High Vacuum Isolation

The VIM furnace distinguishes itself by maintaining a vacuum level of less than 10 Pa.

This is not merely about lowering pressure; it is about evacuating reactive gases. This environment prevents the molten matrix from absorbing gases that would otherwise compromise the structural integrity of the final product.

Inhibiting Unwanted Reactions

In standard melting processes, molten steel aggressively reacts with oxygen and nitrogen in the air.

For T91 steel, these reactions are detrimental. The VIM furnace inhibits these reactions entirely, ensuring the base metal remains chemically stable and free of oxide or nitride inclusions.

Enabling Advanced Alloying

The deep need for VIM in T91 production lies in the specific requirements of its alloy composition, particularly regarding rare earth elements.

The Foundation for Rare Earths

T91 steel production often involves the addition of rare earth elements like Cerium (Ce) and Yttrium (Y).

These elements are highly reactive to oxygen. If introduced into a "dirty" melt, they would immediately oxidize and become impurities rather than alloying agents.

Ensuring Alloying Efficiency

Because the VIM furnace establishes a low-impurity baseline, the added Cerium and Yttrium can perform their intended function.

The vacuum ensures these expensive and critical elements are utilized for structural enhancement rather than being wasted on neutralizing pre-existing contaminants.

Operational Considerations and Trade-offs

While VIM is essential for purity, it introduces specific complexities that must be managed.

Equipment Complexity

VIM furnaces are intricate systems requiring precise synchronization between vacuum pumps, cooling systems, and induction power supplies.

As noted in standard configurations, components like water-cooled interlayers and ceramic-coated inductors require rigorous maintenance to prevent system failure or safety hazards.

Throughput Limitations

The nature of vacuum processing typically necessitates batch production rather than continuous flow.

This focus on quality and purity often comes at the expense of speed and volume, making it less suitable for lower-grade steels where throughput is the priority.

Making the Right Choice for Your Goal

When planning the production line for T91 or similar high-performance alloys, consider how the VIM process aligns with your metallurgical objectives.

- If your primary focus is material purity: The VIM furnace is non-negotiable, as it provides the only reliable method to keep oxygen and nitrogen levels low enough for high-grade specifications.

- If your primary focus is rare earth alloying: You must utilize VIM to prevent the immediate oxidation of elements like Cerium and Yttrium, ensuring they effectively modify the steel's microstructure.

The Vacuum Induction Melting furnace is not just a heating vessel; it is a precision instrument that guarantees the chemical fidelity required for advanced T91 steel production.

Summary Table:

| Feature | VIM Furnace Role in T91 Production | Benefit to Material |

|---|---|---|

| Environment | High Vacuum (< 10 Pa) | Prevents gas absorption and oxidation |

| Purity | Eliminates O2 and N2 reactions | Reduces harmful non-metallic inclusions |

| Alloying | Low-impurity baseline | Protects rare earths (Ce, Y) from oxidation |

| Structural Integrity | Chemical stability | Enhances high-temperature resistance and durability |

Elevate Your Metallurgical Precision with KINTEK

High-performance alloys like T91 demand a vacuum environment that leaves no room for error. KINTEK provides industry-leading Vacuum Induction Melting (VIM) systems and specialized high-temp furnaces designed to meet the rigorous standards of advanced material science. Backed by expert R&D and manufacturing, our customizable solutions—including Vacuum, CVD, Tube, and Muffle systems—ensure your rare earth alloying and purity goals are met with unmatched reliability.

Ready to optimize your ultra-clean melting process? Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

References

- Jun Liu, Xikou He. Effect of Ce-Y Composite Addition on the Inclusion Evolution in T91 Heat-Resistant Steel. DOI: 10.3390/ma18071459

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the role of a vacuum furnace in the solid-phase synthesis of TiC/Cu? Master High-Purity Material Engineering

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering