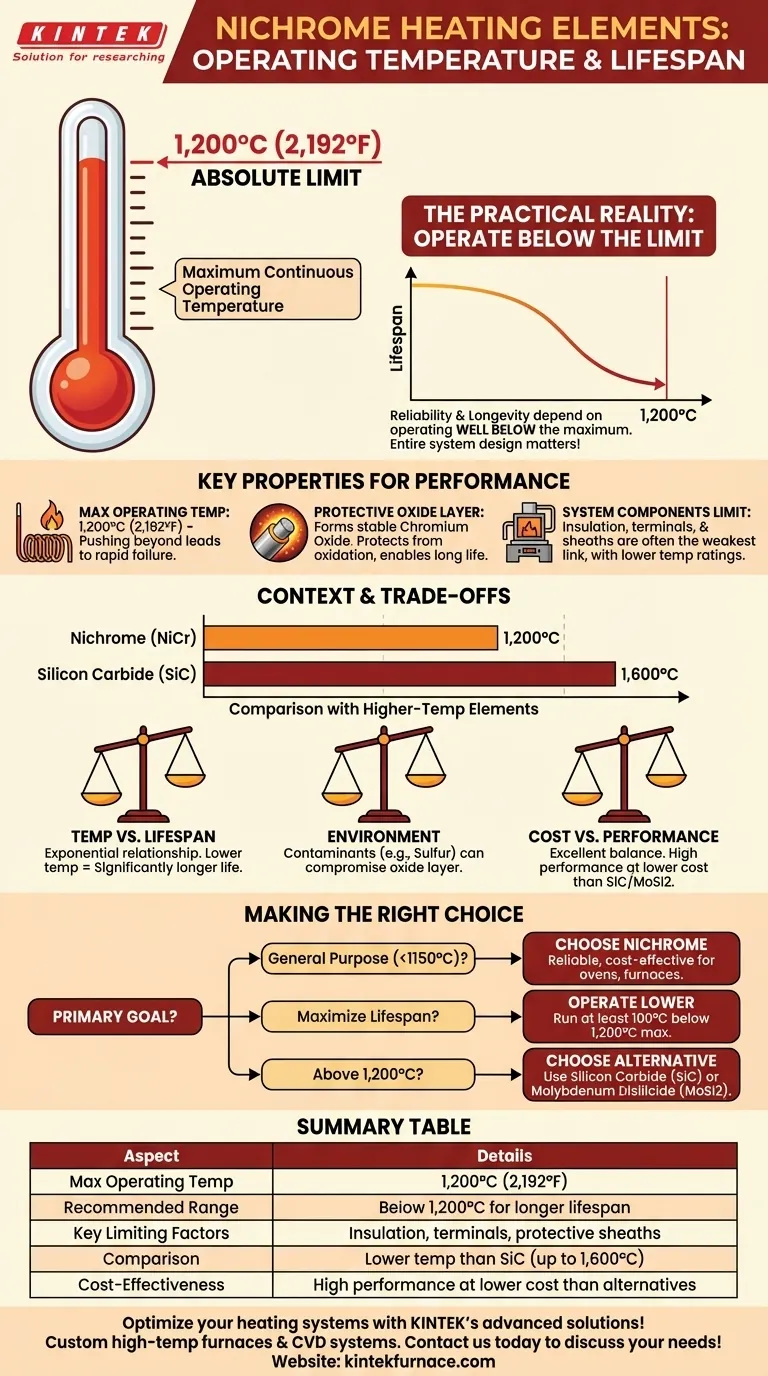

In short, Nichrome heating elements have a maximum continuous operating temperature of approximately 1,200°C (2,192°F). However, this number represents the material's absolute limit, not its practical or recommended operating point for ensuring a long service life. The entire heating system design dictates the true, safe operating temperature.

The key takeaway is that while Nichrome wire can withstand 1,200°C, the reliability and longevity of a heating element depend more on operating it well below this maximum and considering the temperature limits of the entire assembly, including insulation and terminals.

The Properties That Define Nichrome's Performance

To properly apply Nichrome, we must look beyond its temperature ceiling and understand the properties that make it a workhorse for electric heating.

Maximum Operating Temperature

The accepted maximum temperature for Nichrome (typically an 80% nickel, 20% chromium alloy) is 1,200°C (2,192°F). Pushing the material beyond this point leads to rapid degradation and failure.

The Protective Oxide Layer

Nichrome's effectiveness comes from its ability to form a stable, adherent outer layer of chromium oxide when first heated. This layer protects the inner metal from further oxidation, allowing it to function for long periods at high temperatures without burning out.

System Components Limit Performance

A heating element is more than just the wire. The maximum operating temperature is often dictated by the weakest link in the assembly, such as insulation materials (like magnesium oxide), terminals, or protective sheaths, which may have lower temperature ratings than the Nichrome itself.

Putting the Temperature Limit in Context

The 1,200°C figure is only meaningful when compared to other materials and system-level realities. It is a high-performance benchmark but not the peak of heating technology.

Comparison with Higher-Temperature Elements

For applications requiring temperatures above Nichrome's limit, other materials are necessary. For example, Silicon Carbide (SiC) heating elements can operate up to 1,600°C (2,912°F), serving more extreme industrial processes.

The Real-World Operating Window

For maximum reliability and lifespan, engineers typically design systems to run Nichrome elements significantly below their peak temperature. Operating consistently at the 1,200°C limit will drastically shorten the element's life.

Understanding the Trade-offs

Selecting a heating element involves balancing performance, lifespan, and cost. Nichrome's popularity stems from its excellent position within these trade-offs.

Temperature vs. Lifespan

There is a direct and exponential relationship between operating temperature and element lifespan. A small reduction in temperature (e.g., 50-100°C) from the maximum can result in a doubling or tripling of the element's service life. Running at the limit is a choice for performance at the cost of reliability.

Environment and Contamination

The protective chromium oxide layer can be compromised by certain atmospheres. The presence of sulfur, for instance, can lead to rapid corrosion and failure at temperatures well below the stated maximum. The operating environment is a critical design consideration.

Cost vs. Performance

Nichrome offers an exceptional balance of high-temperature performance and cost-effectiveness. While materials like SiC or Molybdenum Disilicide offer higher temperature capabilities, they come at a substantially higher price point, making Nichrome the default choice for a vast range of applications.

Making the Right Choice for Your Application

Use your primary goal to guide your material selection and design parameters.

- If your primary focus is general-purpose heating up to 1150°C: Nichrome is the most reliable and cost-effective choice for applications like ovens, furnaces, and appliances.

- If your primary focus is maximizing element lifespan: Operate your Nichrome element at least 100°C below its 1,200°C maximum to ensure long-term stability.

- If your primary focus is operating above 1200°C: You must move to a different class of material, such as Silicon Carbide (SiC) or Molybdenum Disilicide (MoSi2).

Ultimately, selecting the right heating element requires balancing the material's properties with the practical constraints of your entire system design.

Summary Table:

| Aspect | Details |

|---|---|

| Maximum Operating Temperature | 1,200°C (2,192°F) |

| Recommended Operating Range | Below 1,200°C for longer lifespan |

| Key Limiting Factors | Insulation, terminals, protective sheaths |

| Comparison to Other Elements | Lower temp than SiC (up to 1,600°C) |

| Cost-Effectiveness | High performance at lower cost than alternatives |

Optimize your heating systems with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing reliability and efficiency. Contact us today to discuss how we can support your specific requirements!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance