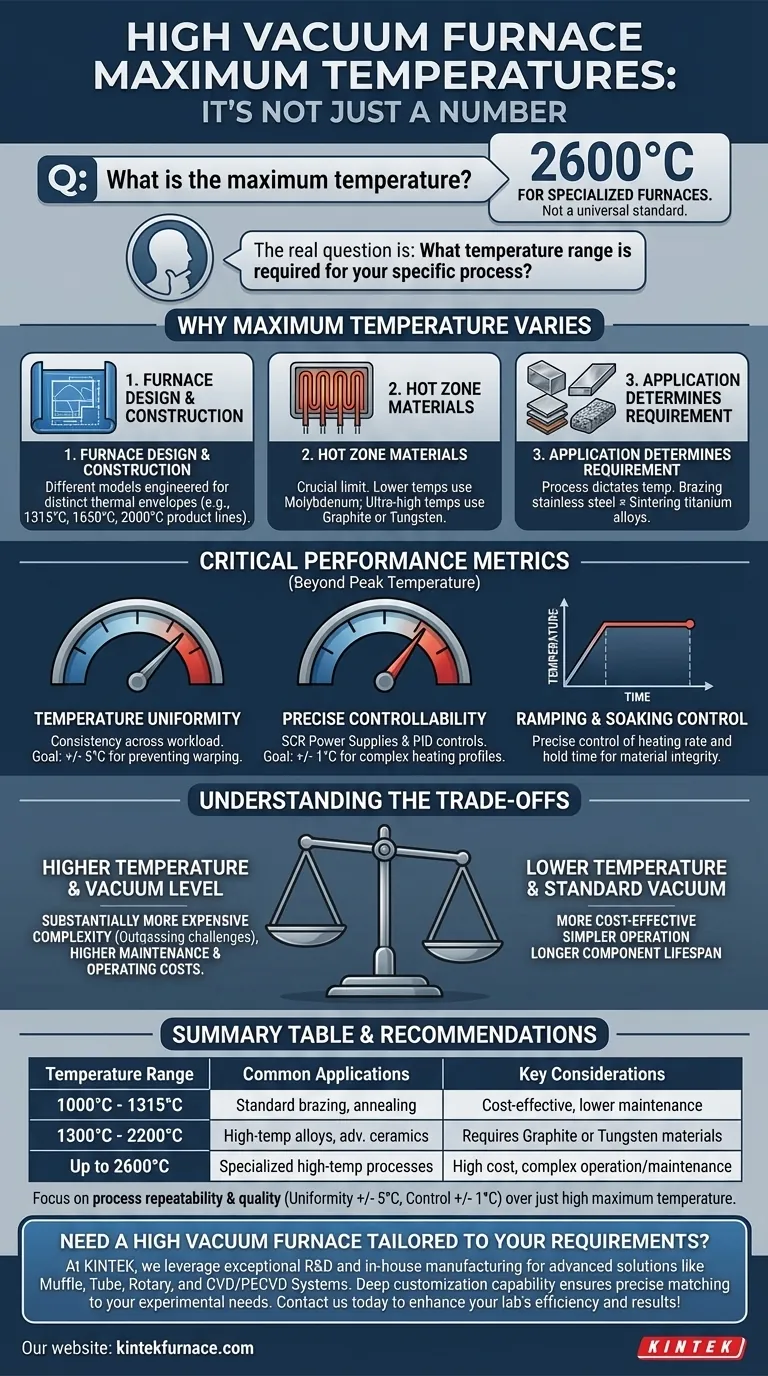

While some specialized high vacuum furnaces can reach 2600°C, this number is not a universal standard. The maximum achievable temperature is fundamentally determined by the furnace's specific design, materials, and intended application, with many common industrial models operating in the 1300°C to 2200°C range.

The question is not "what is the single maximum temperature," but rather "what temperature range is required for a specific process and which furnace is designed to meet it?" The key is matching the furnace's capabilities—defined by its construction—to the thermal demands of your material.

Why Maximum Temperature Varies by Furnace

The peak temperature of a vacuum furnace is not an arbitrary limit. It is a direct consequence of its engineering, materials science, and the specific thermal processes it was built to perform.

Furnace Design Dictates Temperature Range

Different furnace models are engineered for different thermal envelopes. A manufacturer may offer a series of furnaces where each model has a distinct temperature ceiling.

For example, it is common to see product lines structured by temperature capability, such as 1315°C (2400°F), 1650°C (3000°F), or 2000°C (3632°F) models. Each is optimized for processes within its designated range.

The Critical Role of Hot Zone Materials

The "hot zone"—the insulated interior containing the heating elements—is the primary factor limiting temperature. The materials used here must withstand extreme heat without degrading or contaminating the vacuum environment.

Furnaces for lower temperatures might use molybdenum elements, while those for ultra-high temperatures require graphite or tungsten components, which can operate at much higher heats.

Application Determines the Requirement

The material being processed dictates the necessary temperature. A furnace designed for brazing stainless steel has different requirements than one for sintering titanium alloys or advanced magnetic materials.

Processes like high-pressure gas quenching or vacuum sintering of high-temperature alloys inherently push the need for furnaces at the upper end of the temperature spectrum.

Beyond Peak Temperature: Critical Performance Metrics

Simply reaching a high temperature is insufficient for quality thermal processing. Control and uniformity are equally, if not more, important for achieving repeatable, successful results.

Temperature Uniformity

This refers to the consistency of temperature across the entire workload. A specification of +/- 5°C means the temperature will not vary by more than 5 degrees from the setpoint anywhere in the hot zone. This is critical for preventing warping and ensuring consistent material properties.

Precise Controllability

Modern furnaces use SCR Power Supplies and independent PID loop controls to manage heat input with extreme precision. This allows for controllability often within +/- 1°C of the desired setpoint, enabling complex, multi-stage heating profiles.

Ramping and Soaking Control

The rate at which the furnace heats up (ramp rate) and the time it holds at a specific temperature (soak time) are crucial process parameters. Precise control over these variables is essential for the material to achieve its desired metallurgical or chemical changes without thermal shock.

Understanding the Trade-offs

Selecting a furnace based on maximum temperature alone is a common mistake. Higher temperature capability comes with significant trade-offs in cost, complexity, and operation.

Higher Temperature vs. Cost

Furnaces capable of achieving over 2000°C are substantially more expensive. This is due to the cost of exotic hot zone materials like tungsten, more complex power delivery systems, and the advanced cooling required to protect the vessel.

The Interplay with Vacuum Level

Achieving a high temperature and a high vacuum (e.g., 7×10⁻⁴ Pa) simultaneously is a major engineering challenge. At extreme temperatures, materials begin to "outgas," releasing vapor that the vacuum pumps must constantly remove. This can make it difficult to maintain the required vacuum level during the highest temperature stages of a cycle.

Maintenance and Component Lifespan

Operating a furnace consistently near its maximum rated temperature dramatically accelerates the wear on its heating elements and insulation. This results in more frequent maintenance cycles and higher long-term operating costs.

Making the Right Choice for Your Goal

To select the correct furnace, shift your focus from the maximum possible temperature to the specific requirements of your process.

- If your primary focus is standard brazing or annealing: A furnace in the 1000°C to 1315°C range is typically sufficient and more cost-effective.

- If your primary focus is processing high-temperature alloys or advanced ceramics: You must look for specialized furnaces rated for 1650°C to 2200°C or higher.

- If your primary focus is process repeatability and quality: Prioritize specifications like tight temperature uniformity (+/- 5°C) and precise PID control over a slightly higher maximum temperature.

Focusing on the specific thermal requirements of your material and process will always lead to the most effective and efficient furnace selection.

Summary Table:

| Temperature Range | Common Applications | Key Considerations |

|---|---|---|

| 1000°C - 1315°C | Standard brazing, annealing | Cost-effective, lower maintenance |

| 1300°C - 2200°C | High-temperature alloys, advanced ceramics | Requires specialized materials like graphite or tungsten |

| Up to 2600°C | Specialized high-temperature processes | High cost, complex operation, and maintenance |

| - | - | Temperature uniformity (±5°C) and precise control (±1°C) critical for quality |

Need a high vacuum furnace tailored to your specific temperature and process requirements? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise matching to your unique experimental needs, whether for standard brazing or high-temperature alloy processing. Contact us today to discuss how our furnaces can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety