In a dental laboratory, the primary function of a pressing furnace is to fabricate ceramic restorations by heating a ceramic ingot until it becomes soft and then physically pressing it into a pre-made mold. This process is essential for creating highly accurate and aesthetic dental components like crowns, inlays, and onlays from specific materials such as lithium disilicate.

The crucial takeaway is that the type of furnace a lab requires is dictated entirely by the dental material being used. A pressing furnace is specifically for "pressable" ceramics, which is a fundamentally different process from the "sintering" required for materials like zirconia.

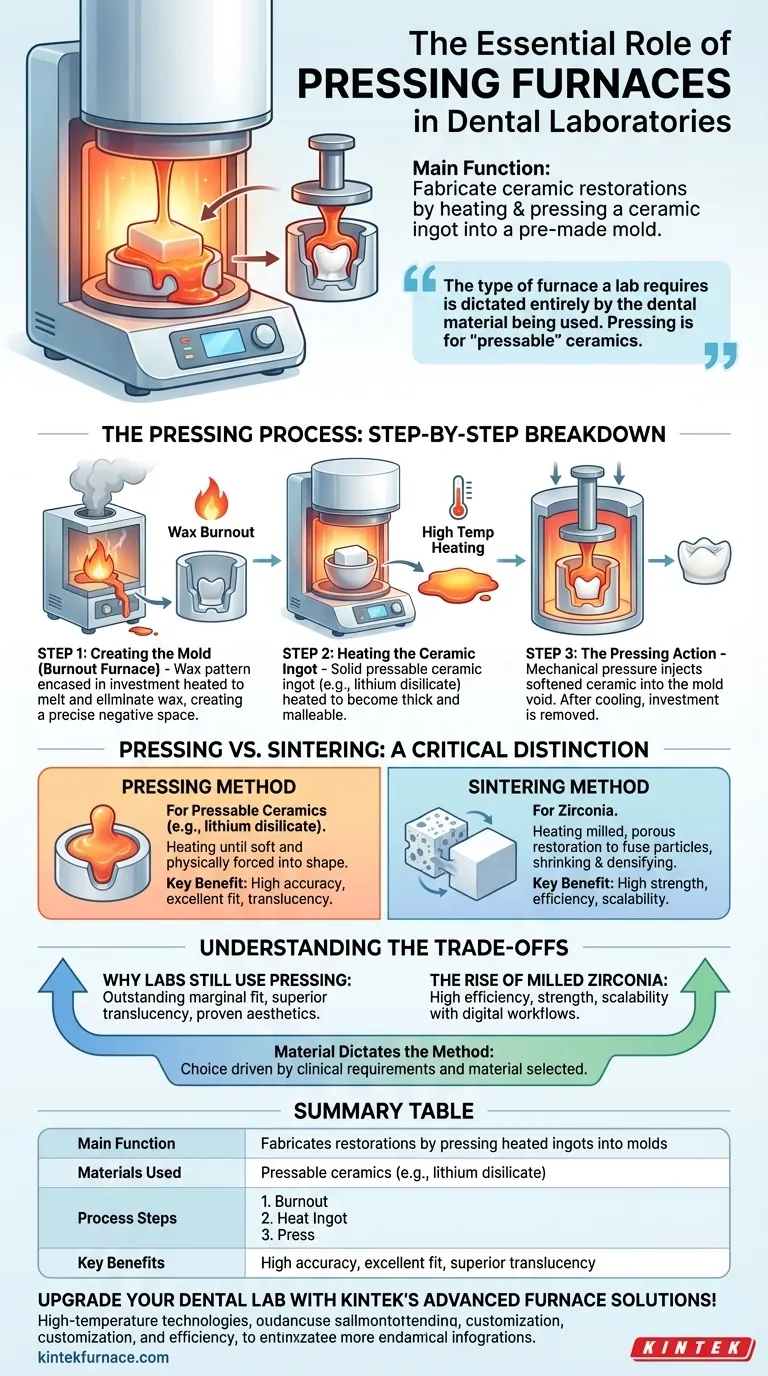

The Pressing Process: A Step-by-Step Breakdown

A pressing furnace is a key component in what is essentially a high-tech "lost-wax" casting technique for ceramics. The process involves several precise steps to transform a raw ceramic ingot into a final restoration.

Step 1: Creating the Mold with a Burnout Furnace

Before the pressing furnace is used, a mold must be created. A wax pattern of the final restoration is made and then encased in a heat-resistant material called an investment.

This assembly is then placed in a burnout furnace. The furnace heats up, melting and eliminating the wax completely. This leaves a precisely detailed negative space, or mold, inside the hardened investment material.

Step 2: Heating the Ceramic Ingot

A solid ingot of a pressable ceramic, like lithium disilicate, is selected. This ingot, along with the investment mold, is placed into the pressing furnace.

The furnace's program heats both components to a specific, high temperature. This heat softens the ceramic ingot, transforming it from a hard solid into a thick, malleable, almost glass-like consistency.

Step 3: The Pressing Action

Once the target temperature is reached, a ceramic or alumina plunger within the furnace applies mechanical pressure.

This pressure forces the softened ceramic material out of its crucible and injects it into the hollow void within the investment mold, filling every detail of the space left by the original wax pattern. After a controlled cooling cycle, the investment is removed to reveal the final pressed ceramic restoration.

Pressing vs. Sintering: A Critical Distinction

The terms "pressing" and "sintering" are often used in the context of dental furnaces, but they describe two distinct processes for two different material classes. Confusing them can lead to significant errors.

The Pressing Method: For Pressable Ceramics

Pressing involves heating a material until it is soft enough to be physically forced into a shape. It is the required method for materials like lithium disilicate (e.g., e.max Press) and other leucite-reinforced ceramics.

The Sintering Method: For Zirconia

Sintering is used for materials like zirconia. Restorations are first milled from a soft, chalk-like block of pre-sintered zirconia.

This porous "green state" restoration is then placed in a sintering furnace, which heats it to an extremely high temperature (often over 1500°C). The material is not melted; instead, the heat causes the individual zirconia particles to fuse together, causing the restoration to shrink, densify, and gain its immense final strength.

The Glazing and Staining Step

Nearly all ceramic restorations, whether pressed or sintered, require a final firing step. A separate porcelain or glazing furnace is used to fire on stains for color characterization and apply a final glaze for a smooth, natural-looking surface. Many modern furnaces combine sintering and glazing functions.

Understanding the Trade-offs

The choice between a pressing workflow and a milling/sintering workflow involves distinct considerations in materials, labor, and technology.

Why Labs Still Use Pressing

Pressing technology is valued for its ability to produce restorations with outstanding marginal fit and translucency. The lost-wax technique is exceptionally precise, and for certain aesthetic cases, many technicians prefer the proven results of pressed ceramics.

The Rise of Milled Zirconia

Digital workflows involving intraoral scanning, CAD design, and milling have become dominant. This process, which culminates in sintering zirconia, offers high efficiency, strength, and scalability that is difficult to match with the more labor-intensive pressing technique.

Material Dictates the Method

Ultimately, the choice is not about one furnace being universally "better." The decision is driven by the clinical requirements and the material selected to meet them. A lab specializing in high-strength posterior bridges will need a sintering furnace for zirconia, while one known for highly aesthetic anterior veneers will require a pressing furnace for lithium disilicate.

Making the Right Choice for Your Goal

To properly equip a dental lab, you must align your furnace technology with the materials you intend to process.

- If your primary focus is fabricating with pressable ceramics like lithium disilicate: You require a pressing furnace to heat and inject ceramic ingots into investment molds.

- If your primary focus is working with monolithic zirconia restorations: You need a sintering furnace to densify and harden the material after it has been milled.

- If your primary focus is achieving the final aesthetic on any ceramic restoration: You need a porcelain or glazing furnace to fire on stains and glazes.

Understanding that the restorative material dictates the required technology is the key to equipping your laboratory for success.

Summary Table:

| Aspect | Details |

|---|---|

| Main Function | Fabricates ceramic restorations by heating and pressing ceramic ingots into molds |

| Materials Used | Pressable ceramics (e.g., lithium disilicate) |

| Process Steps | 1. Mold creation with burnout furnace 2. Heating ceramic ingot 3. Pressing into mold |

| Key Benefits | High accuracy, excellent marginal fit, superior translucency |

| Comparison to Sintering | Pressing is for soft ceramics; sintering is for zirconia densification |

Upgrade Your Dental Lab with KINTEK's Advanced Furnace Solutions!

Are you aiming to enhance your lab's capabilities in fabricating precise ceramic restorations? KINTEK specializes in high-temperature furnace technologies tailored for dental laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by exceptional R&D and in-house manufacturing. With strong deep customization capabilities, we can design furnaces that precisely meet your unique needs, whether you're working with pressable ceramics like lithium disilicate or require sintering solutions for zirconia.

By partnering with KINTEK, you'll benefit from improved efficiency, superior material performance, and reliable support to elevate your dental restorations. Don't settle for less—contact us today to discuss how our solutions can drive your lab's success!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures