At its core, a muffle furnace is a box-shaped, high-temperature oven. Its defining operational characteristic is the use of an isolated inner chamber—the "muffle"—to heat materials uniformly without any direct contact from electric heating elements or combustion byproducts. This ensures the chemical purity of the sample is maintained throughout the process.

The critical takeaway is that a muffle furnace's value lies not just in its ability to reach high temperatures, but in its fundamental design for isolation. This prevents sample contamination, making it an indispensable tool for applications where material integrity and process repeatability are non-negotiable.

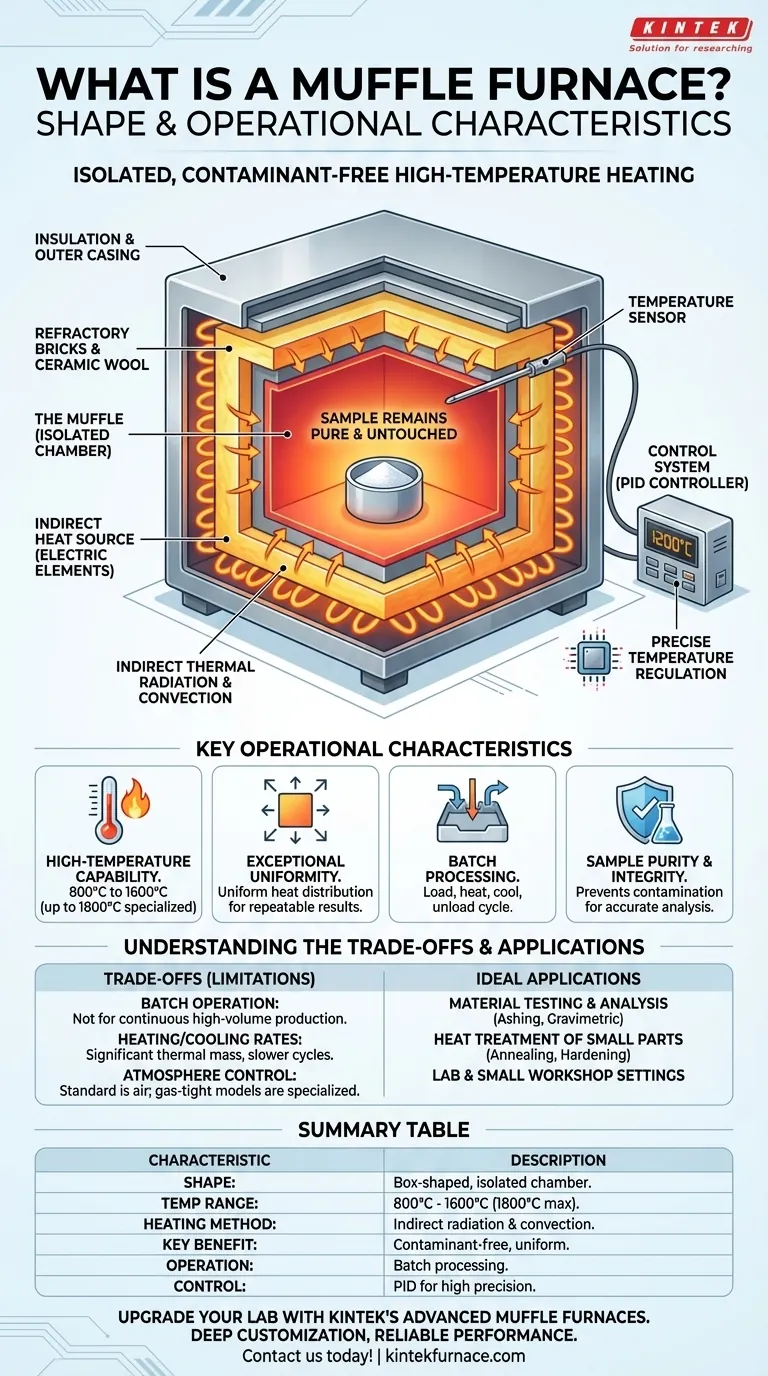

How a Muffle Furnace Achieves Precise, Contaminant-Free Heating

To understand its operation, you must look at its key components and how they interact to create a controlled thermal environment. The design is elegantly simple but highly effective.

The Muffle: An Insulated Inner Chamber

The "muffle" is the heart of the furnace. It is a separate, enclosed chamber, typically made of ceramic or other refractory materials, that holds the sample.

Heat is transferred to this chamber through thermal radiation and convection from the external heat source. This indirect heating method is what prevents contamination from fuel or degrading heating elements.

The Heat Source: Electric Elements or Gas Burners

The energy to heat the muffle is provided by an external source.

Most modern lab-scale furnaces use high-resistance electric heating elements (made from materials like Kanthal or nickel-chromium) that surround the muffle. Some industrial models may use natural gas or propane burners.

The Control System: The Brain of the Operation

Precise temperature is not optional; it is a core requirement. This is managed by a sophisticated control system.

A temperature sensor (such as a J-type thermocouple) constantly measures the internal temperature of the chamber.

This data is fed to a PID (Proportional-Integral-Derivative) controller. This controller intelligently pulses power to the heating elements (often via a Solid-State Relay or SSR) to maintain the set temperature with exceptional accuracy, minimizing overshoot and fluctuation.

The Insulation: Maximizing Efficiency and Safety

To reach and maintain temperatures that can exceed 1600°C (2900°F), the entire structure must be heavily insulated.

Materials like refractory bricks and high-density ceramic or glass wool blankets are used. This insulation ensures maximum thermal efficiency, keeps the outer casing safe to touch, and contributes to stable, uniform temperatures within the chamber.

Key Operational Characteristics

The furnace's physical design directly leads to its primary operational benefits.

High-Temperature Capability

Muffle furnaces are designed for high-heat applications, with typical operating ranges from 800°C to 1600°C, and some specialized models reaching 1800°C or higher.

Exceptional Temperature Uniformity

Because the heat radiates inward from all sides of the muffle, the chamber achieves a highly uniform temperature distribution. This is critical for ensuring that an entire sample receives the same treatment, leading to accurate and repeatable test results.

Batch Processing Operation

These furnaces are designed for batch processing. Materials are loaded through a single door, remain stationary for the entire heating and cooling cycle, and are then unloaded. This simple operation makes them easy to use and maintain.

Sample Purity and Integrity

This is the most crucial characteristic. By isolating the sample from the heat source, the furnace prevents any chemical reactions or contamination, which is essential for analytical chemistry (like ashing), materials science research, and quality control.

Understanding the Trade-offs

While powerful, a muffle furnace is not the universal solution for all heating needs. Objectivity requires acknowledging its limitations.

Batch vs. Continuous Processing

The fundamental load-heat-unload cycle makes muffle furnaces inherently unsuited for high-volume, continuous production lines. For those applications, a tunnel or conveyor furnace would be more appropriate.

Heating and Cooling Rates

The same heavy insulation that provides thermal stability also gives the furnace significant thermal mass. This means many models can take a considerable amount of time to heat up and, more importantly, to cool down before samples can be safely removed.

Atmosphere Control

A standard muffle furnace operates with a normal air atmosphere. While some advanced models are equipped with gas-tight doors and ports to introduce inert gases (like nitrogen or argon), this is not a default feature. If you require a specific, controlled atmosphere, you must ensure the model you choose supports it.

Is a Muffle Furnace the Right Tool for Your Application?

Your choice depends entirely on your specific objective.

- If your primary focus is material testing or analysis: The furnace's uniform, contaminant-free heating provides the highly accurate and repeatable results required for ashing, gravimetric analysis, or studying material properties.

- If your primary focus is heat treatment of small parts: The precise temperature control and batch operation are ideal for processes like annealing, hardening, tempering, or sintering components in a lab or small workshop setting.

- If your primary focus is high-volume, continuous production: The batch nature of a muffle furnace is inefficient; you should investigate a conveyor or tunnel furnace designed for continuous throughput.

Understanding these core principles of isolation and control empowers you to leverage a muffle furnace for its intended purpose with precision and confidence.

Summary Table:

| Characteristic | Description |

|---|---|

| Shape | Box-shaped oven with isolated inner chamber |

| Temperature Range | 800°C to 1600°C, up to 1800°C in specialized models |

| Heating Method | Indirect via thermal radiation and convection |

| Key Benefit | Prevents sample contamination, ensures purity |

| Operation Type | Batch processing for stationary samples |

| Control System | PID controller with temperature sensors for precision |

Upgrade your laboratory with KINTEK's advanced muffle furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, delivering contaminant-free heating and reliable performance. Contact us today to discuss how we can enhance your material testing and heat treatment processes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency