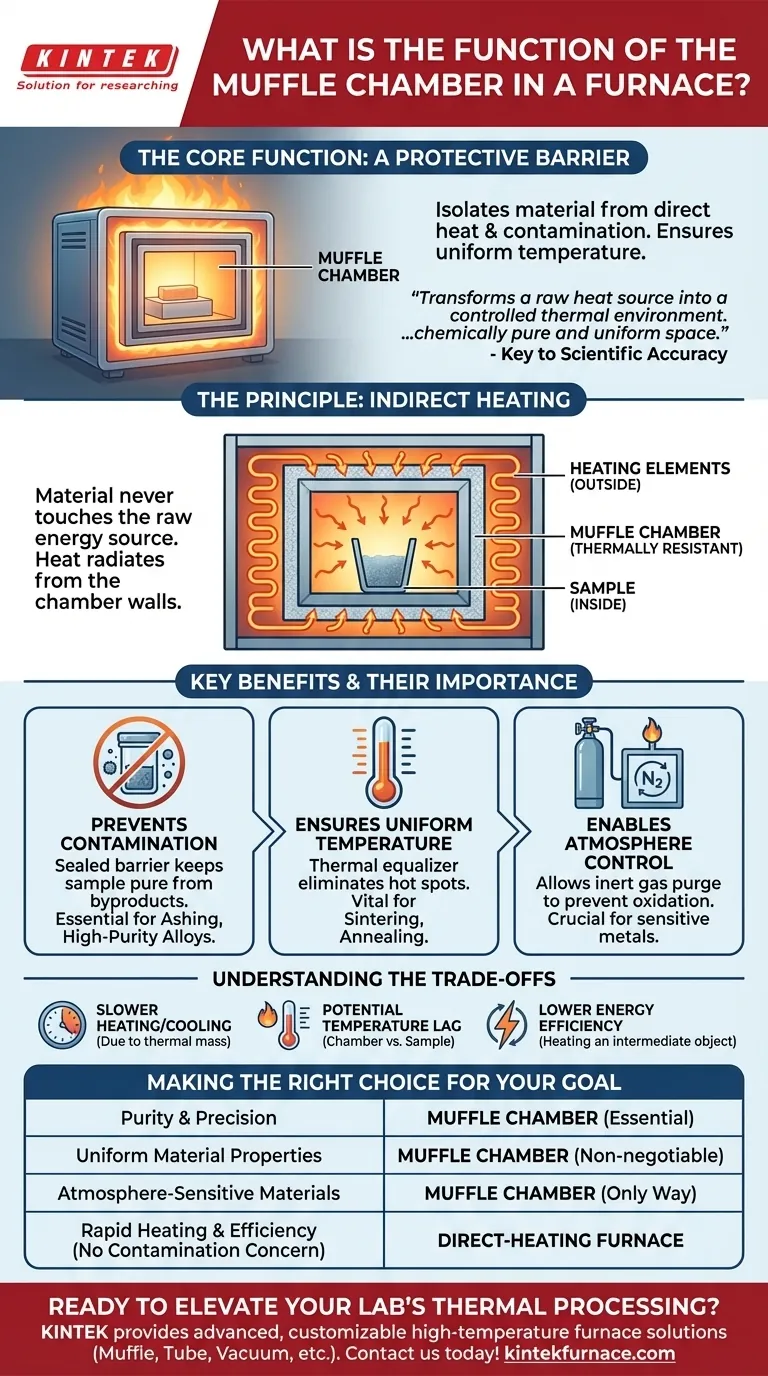

In simple terms, the function of the muffle chamber in a furnace is to act as a protective barrier. It physically isolates the material being heated from direct contact with the heating source—whether that be flames, combustion gases, or electric elements—to prevent contamination and ensure the temperature is applied uniformly.

The muffle chamber transforms a raw heat source into a controlled thermal environment. Its true function is not just to heat, but to create a chemically pure and uniform space, which is critical for scientific accuracy and high-quality material processing.

The Principle of Indirect Heating

A muffle furnace operates on a simple but powerful principle: indirect heating. Understanding this is key to grasping why the muffle chamber is so important.

What is a "Muffle"?

The term "muffle" refers to the insulated inner chamber of the furnace. It is essentially a box made of a thermally resistant material that contains your sample.

Separating the Sample from the Heat Source

In a typical electric muffle furnace, the heating elements are wrapped around the outside of the muffle chamber. In a fuel-fired version, the combustion occurs outside this chamber.

The material inside never touches the raw energy source. This separation is the defining characteristic of a muffle furnace.

How Heat is Transferred

Heat radiates from the elements or combustion zone, warming the walls of the muffle chamber. The chamber's walls then radiate this heat evenly inward, blanketing the sample in a consistent, uniform thermal environment.

Key Functions and Their Importance

This design of indirect heating provides three critical advantages that are impossible to achieve with direct heating methods.

Preventing Chemical Contamination

For many scientific and industrial processes, purity is paramount. Byproducts from fuel combustion or microscopic particles shedding from electric heating elements can contaminate a sample, invalidating results or ruining the material.

The muffle chamber acts as a sealed barrier, ensuring the only thing affecting your sample is heat. This is essential for processes like ashing, where the precise residue must be measured, or creating high-purity alloys.

Ensuring Uniform Temperature

Direct exposure to a heating element or flame creates intense hot spots. A muffle chamber solves this by acting as a thermal equalizer.

It absorbs the intense heat and radiates it gently and evenly from all directions. This uniformity is vital for processes like sintering or annealing, where the entire material must experience the exact same temperature profile to achieve the desired crystalline structure and strength.

Enabling Atmosphere Control

Because the muffle is an enclosed space, it allows you to control the gaseous environment around the sample.

You can purge the chamber of oxygen and fill it with an inert gas like nitrogen or argon. This is crucial for heat-treating metals that would otherwise oxidize (rust) at high temperatures or for specific chemical reactions that must occur in an oxygen-free environment.

Understanding the Trade-offs

While powerful, the muffle design is not without its compromises. Objectivity requires acknowledging them.

Slower Heating and Cooling Rates

The muffle chamber itself has thermal mass. It takes time and energy to heat the chamber before that heat can be transferred to the sample. This results in slower heat-up and cool-down cycles compared to direct-fire furnaces.

Potential for Temperature Lag

The furnace's temperature controller measures the temperature of the chamber, which can be slightly different from the actual temperature of the sample inside. For extremely precise work, this thermal lag must be accounted for.

Energy Efficiency

Indirect heating is inherently less efficient than direct heating. You are using energy to heat an intermediate object (the muffle) rather than applying it directly to the workpiece. Some energy is always lost in this transfer.

Making the Right Choice for Your Goal

The decision to use a furnace with a muffle chamber comes down to the specific requirements of your process.

- If your primary focus is material purity and precision: The muffle chamber is essential to prevent contamination and guarantee reliable analytical results.

- If your primary focus is uniform material properties: The muffle's ability to eliminate hot spots is non-negotiable for processes like annealing or glass tempering.

- If your primary focus is processing atmosphere-sensitive materials: A sealed muffle chamber is the only way to reliably control the gaseous environment and prevent oxidation.

- If your primary focus is rapid heating and maximum energy efficiency: A direct-heating furnace may be a more suitable choice, provided contamination is not a concern.

Understanding the muffle chamber's role moves you from simply using a furnace to strategically controlling a thermal process.

Summary Table:

| Function | Description | Key Benefit |

|---|---|---|

| Prevents Contamination | Acts as a barrier between sample and heat source | Ensures material purity for accurate results |

| Ensures Uniform Temperature | Radiates heat evenly from chamber walls | Eliminates hot spots for consistent processing |

| Enables Atmosphere Control | Sealed chamber allows gas environment manipulation | Prevents oxidation and supports specific reactions |

Ready to elevate your lab's thermal processing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our furnaces can enhance purity, uniformity, and efficiency in your processes!

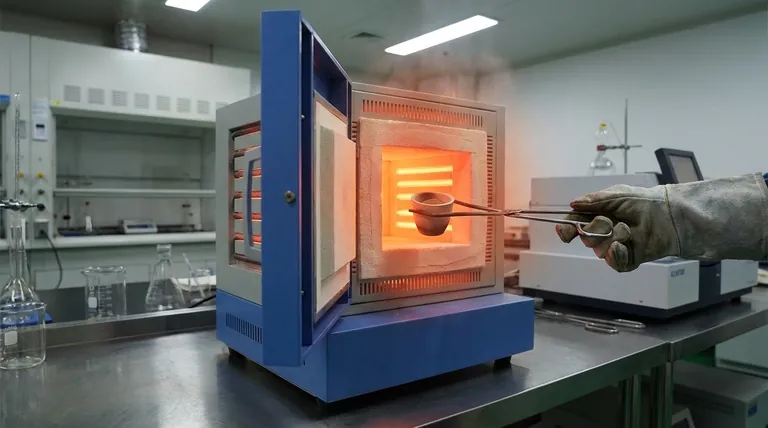

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing