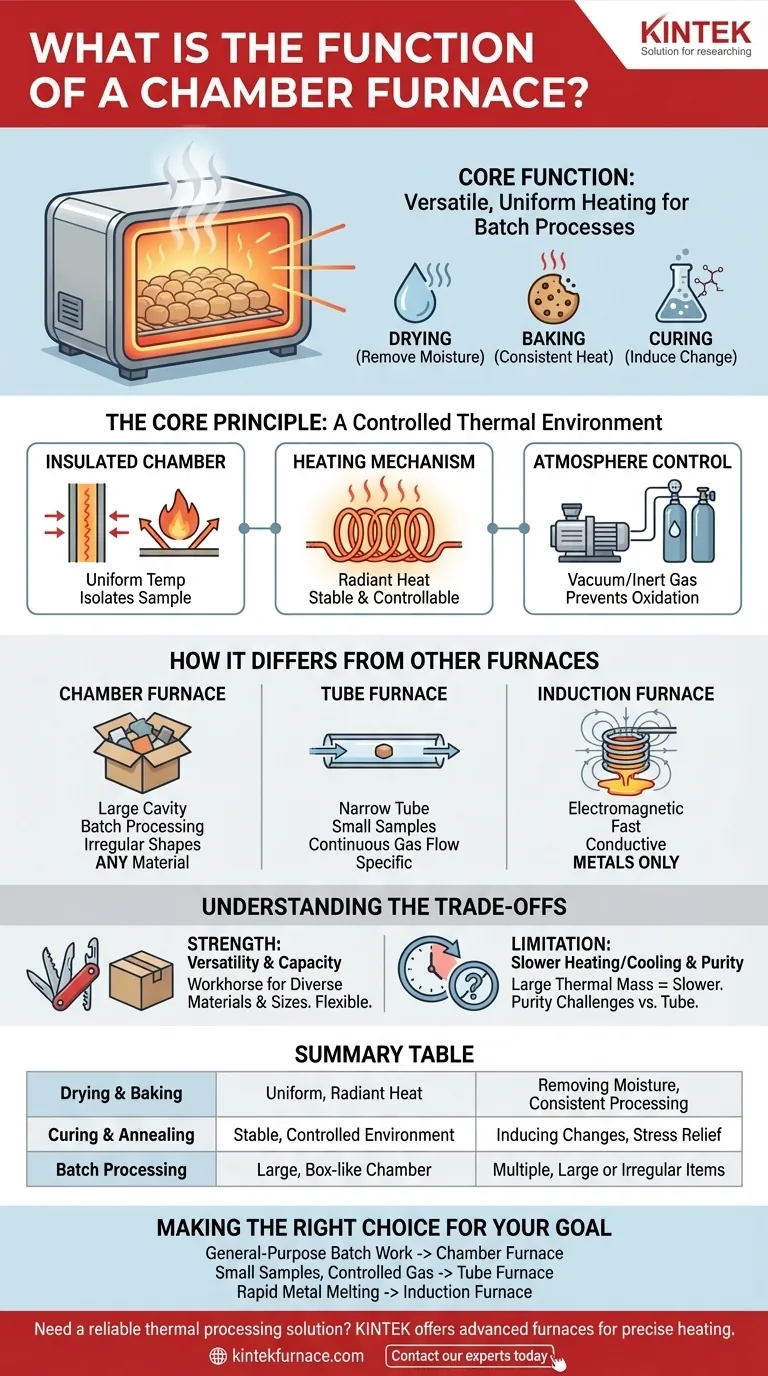

At its core, a chamber furnace is a general-purpose thermal processing tool used in a laboratory or industrial setting. Its primary functions are drying materials to remove moisture, baking samples with consistent heat, and curing substances to induce a physical or chemical change. The defining feature is its insulated, box-like chamber that provides a large, uniform heating environment.

The function of a chamber furnace is to provide versatile and uniform heating for batch processes. Unlike more specialized equipment, its value lies in its simplicity and ability to handle a wide variety of sample sizes and applications, from simple drying to complex curing cycles.

The Core Principle: A Controlled Thermal Environment

The design of a chamber furnace is centered on creating a stable and uniform heating zone. This is achieved through a few key components working in concert.

The Insulated Chamber

The main body is an insulated box, typically made with refractory materials. This design serves two purposes: it maintains a highly uniform temperature throughout the interior and isolates the sample from direct contact with the heating elements, preventing hot spots and ensuring even processing.

The Heating Mechanism

Most chamber furnaces use resistive heating elements placed around the walls of the chamber. When electricity passes through them, they heat up and radiate thermal energy into the chamber. This method provides stable, controllable heat suitable for a vast range of temperatures and applications.

Atmosphere Control

While basic models operate in ambient air, many chamber furnaces can be sealed and modified for atmosphere control. By evacuating the air to create a vacuum or introducing an inert gas like argon, the furnace can prevent oxidation and other undesirable chemical reactions with the atmosphere, which is critical when working with sensitive materials.

How It Differs From Other Furnaces

Understanding the chamber furnace requires comparing it to other common thermal equipment. The choice of furnace depends entirely on the material and the desired outcome.

Chamber Furnace vs. Tube Furnace

A tube furnace heats samples inside a narrow cylindrical tube. This design is ideal for processing small samples or for applications requiring a very specific, pure, and continuous flow of gas over the material.

A chamber furnace, in contrast, offers a large, open cavity. It is better suited for processing larger individual items, multiple samples at once (batch processing), or objects with irregular shapes that would not fit in a tube.

Chamber Furnace vs. Induction Furnace

An induction furnace uses a completely different heating principle. It generates a high-frequency electromagnetic field to heat conductive materials, primarily metals. This process is extremely fast and can even stir molten metal, making it perfect for melting and creating alloys.

A chamber furnace uses radiant heat, which is slower but far more versatile. It can heat any type of material, including non-conductive ceramics, polymers, and composites, not just metals.

Understanding the Trade-offs

No single tool is perfect for every job. The chamber furnace's versatility comes with specific limitations you must consider.

Strength: Versatility and Capacity

The chamber furnace is the workhorse of the thermal processing world. Its simple design allows it to perform drying, baking, curing, annealing, and sintering on a wide variety of materials and sample sizes. It is the most flexible option for a general-purpose lab.

Limitation: Slower Heating and Cooling

Due to the large thermal mass of the insulated chamber, these furnaces heat up and cool down relatively slowly compared to induction or tube furnaces. They are not ideal for applications that require rapid temperature cycling.

Limitation: Atmosphere Purity

While chamber furnaces can support vacuum or inert gas, the large volume and door seals can make it challenging to achieve the ultra-high purity atmosphere possible in a dedicated tube furnace. For highly sensitive materials, a tube furnace often provides superior control.

Making the Right Choice for Your Goal

Selecting the correct furnace is critical for achieving reliable and repeatable results. Your decision should be guided by your primary application.

- If your primary focus is general-purpose thermal processing: The chamber furnace's capacity for batch work and its ability to handle diverse materials and large objects make it the standard choice.

- If your primary focus is processing small samples in a highly controlled gas atmosphere: The specific geometry and superior gas flow control of a tube furnace will deliver better results.

- If your primary focus is rapidly melting or alloying conductive metals: The electromagnetic heating and inherent stirring action of an induction furnace are unmatched for speed and uniformity.

Choosing the right furnace begins with a clear understanding of your specific thermal processing objective.

Summary Table:

| Function | Key Feature | Best For |

|---|---|---|

| Drying & Baking | Uniform, radiant heat | Removing moisture, consistent thermal processing |

| Curing & Annealing | Stable, controlled environment | Inducing physical/chemical changes, stress relief |

| Batch Processing | Large, box-like chamber | Multiple samples, large or irregularly shaped items |

Need a reliable thermal processing solution for your lab?

At KINTEK, we understand that precise and uniform heating is critical for your research and production. Our chamber furnaces are engineered for exceptional performance in drying, baking, curing, and other batch processes.

Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Chamber, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Let us help you achieve superior results. Contact our experts today to discuss your specific application and find the perfect furnace for your needs!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis