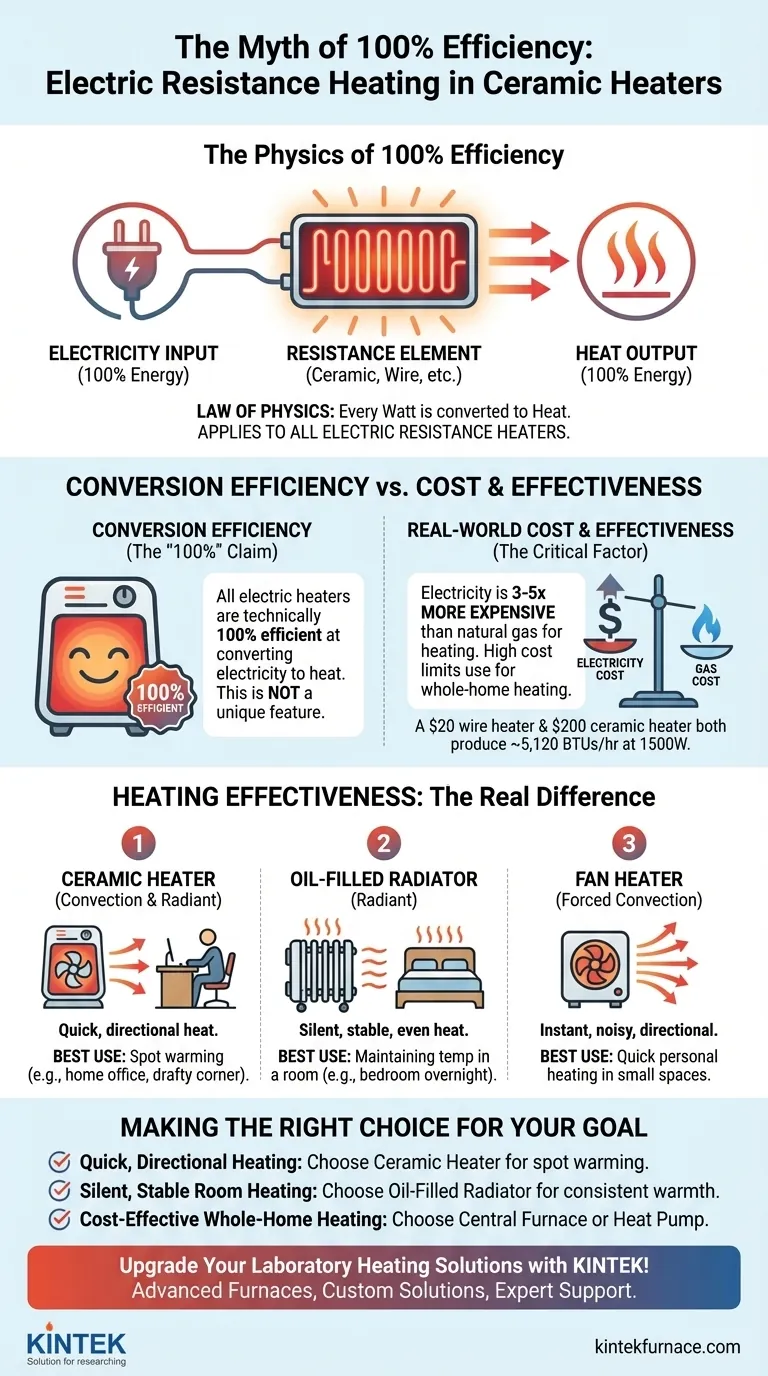

From a technical standpoint, all electric resistance heaters, including ceramic models, are 100% energy efficient. This is a law of physics: every watt of electricity drawn from the wall is converted directly into thermal energy, or heat. There is no waste in the energy conversion process itself.

While all electric heaters are 100% efficient at converting electricity to heat, this metric is profoundly misleading. The critical factor is not the efficiency of the device, but the high cost of electricity as a heating fuel compared to alternatives like natural gas.

The Physics of 100% Efficiency

To understand why claims of "high efficiency" in electric heaters are technically true but practically irrelevant, we must distinguish between energy conversion and heating effectiveness.

The First Law of Thermodynamics at Work

An electric heater is a simple circuit. As electricity passes through a resistor (in this case, a ceramic element), the resistance impedes the flow of electrons, generating heat.

Because energy cannot be created or destroyed, all the electrical energy entering this simple system must be converted into another form. In this case, it is converted entirely into heat.

"Efficiency" Refers to Conversion, Not Cost

The 100% efficiency figure refers only to the conversion of electricity into BTUs (British Thermal Units) of heat. It does not measure how effectively that heat warms your room or how much it costs to generate.

A $20 wire-element heater and a $200 ceramic heater are both 100% efficient in this regard. They turn the same amount of electricity into the same amount of heat.

A Universal Trait, Not a Unique Feature

This 100% efficiency is not a special feature of ceramic heaters. It applies to all electric resistance heaters, including oil-filled radiators, simple fan heaters, and quartz infrared models. Any marketing that presents this as a unique benefit is using a universal fact to imply a competitive advantage.

The Real Question: Heating Effectiveness

The meaningful difference between heater types is not their energy efficiency but their method of heat delivery. This affects how comfortable you feel and which applications they are best suited for.

Ceramic Heaters (Convection and Radiant)

Ceramic heaters warm up a self-regulating ceramic plate and typically use a fan to blow air across it. This provides a quick blast of warm air (convection), making them feel effective for warming a person or a small, targeted area very quickly.

Oil-Filled Radiators (Radiant)

These heaters warm oil sealed inside fins, which then radiates heat silently and evenly into the room. They are slower to heat up but are excellent for maintaining a stable, comfortable temperature in a well-defined space like a bedroom.

Fan Heaters (Forced Convection)

These are the simplest models, blowing air directly over a hot electrical coil. They provide instant, directional heat but can be noisy, and the warmth dissipates almost immediately after they are turned off.

The True Cost of Electric Heat

The core issue is the source fuel. Generating a unit of heat (one BTU) with electricity is often three to five times more expensive than generating it by burning natural gas in a furnace.

This is why electric resistance heat is rarely used for whole-home heating and is best reserved for specific, limited applications. A standard 1,500-watt portable heater, regardless of type, produces the same amount of heat (about 5,120 BTUs per hour) and costs the same to operate.

Understanding the Trade-offs

Choosing the right heater means ignoring the "100% efficiency" claim and focusing on the practical realities of cost and application.

The "Efficiency" Marketing Trap

Marketers use the 100% efficiency figure to make a product sound scientifically superior or more economical. As established, it is neither. This fact is used to distract from the high operational cost of using electricity for heat.

Heat Output is Standardized

In the United States, standard home outlets limit portable heaters to a maximum of 1,500 watts. This means every compliant portable electric heater produces the exact same maximum quantity of heat. The only difference is in how that heat is delivered.

Use Case is Everything

A ceramic heater is not inherently "better" than an oil-filled radiator; it is simply better for a different task. Judging a heater outside the context of its intended use is the most common mistake.

Making the Right Choice for Your Goal

Forget efficiency numbers and focus on the job you need the heater to do.

- If your primary focus is quick, directional heating for a person or a small spot: A ceramic heater is an excellent choice for warming a home office workspace or a drafty living room corner.

- If your primary focus is silent, stable heating for an entire small room: An oil-filled radiator is superior for maintaining a consistent temperature in a bedroom or den overnight.

- If your primary focus is cost-effective whole-home heating: An electric resistance heater is the wrong tool; a central furnace or a modern heat pump will be vastly more economical to operate.

By understanding the difference between energy conversion and real-world heating effectiveness, you can confidently select the right tool for your specific heating needs.

Summary Table:

| Heater Type | Key Features | Best Use Cases |

|---|---|---|

| Ceramic Heater | Quick, directional heat via fan; ideal for spot warming | Home offices, small areas needing fast heat |

| Oil-Filled Radiator | Silent, stable radiant heat; excellent for consistent warmth | Bedrooms, dens for overnight use |

| Fan Heater | Instant, forced convection; noisy but immediate | Quick personal heating in small spaces |

| General Electric Resistance | 100% energy conversion efficiency; high electricity cost | Limited applications due to operational expense |

Upgrade Your Laboratory Heating Solutions with KINTEK!

Struggling with inefficient heating systems in your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratory needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements.

- Precision and Reliability: Ensure accurate temperature control and uniform heating for consistent results.

- Customization: Get furnaces designed to fit your specific applications, enhancing efficiency and reducing costs.

- Expert Support: Benefit from our technical expertise to optimize your heating processes.

Don't let high operational costs hold you back—contact us today to discuss how our solutions can transform your lab's performance. Reach out now via our contact form!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation