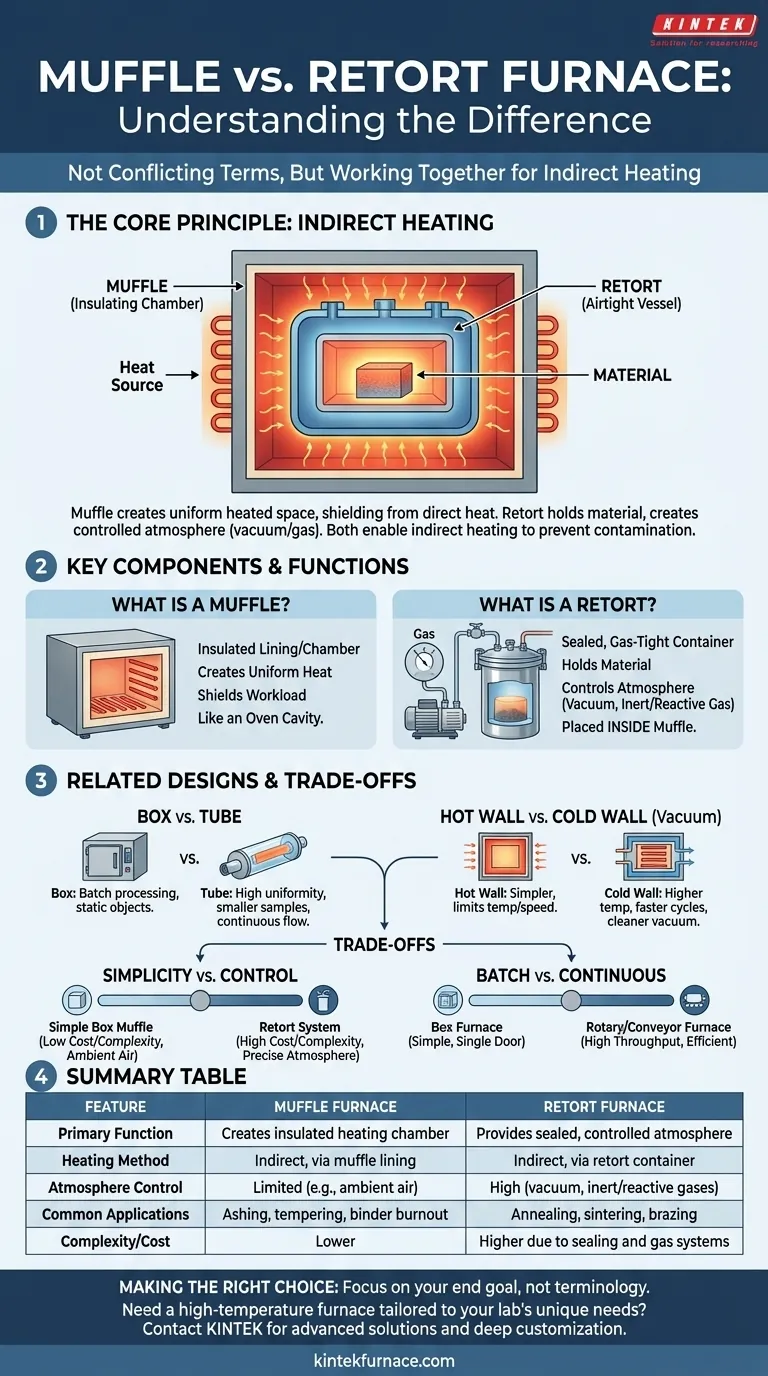

Technically, there is no conflict between the terms. A "retort" is an airtight vessel used to hold a material, while a "muffle" is the insulating chamber that separates the heating elements from that vessel. In practice, the terms are often used interchangeably to describe a furnace that heats its contents indirectly, protecting them from the direct heat source and combustion byproducts.

The distinction between "muffle" and "retort" is less about two different types of furnaces and more about two components that work together. The crucial takeaway is that both enable indirect heating, a method designed to control the processing atmosphere and prevent contamination of the material.

The Core Principle: Indirect Heating for Process Control

The fundamental concept behind both muffle and retort furnaces is the separation of the workload from the heat source. This design is critical for any process where the atmosphere around the material must be precisely controlled.

What is a Muffle?

A muffle is the furnace's insulated lining or a separate chamber, typically made of high-temperature ceramic. Its primary job is to create a uniform, heated space while shielding the workload from direct radiation from the heating elements.

Think of it as the oven cavity itself, ensuring even heat without direct contact with the flames or glowing electrical coils.

What is a Retort?

A retort is a sealed, gas-tight container that holds the material being processed. It is placed inside the muffle. Its primary job is to create a controlled atmosphere—be it a vacuum, an inert gas like argon, or a reactive gas.

The muffle heats the outside of the retort, and the retort, in turn, heats the material inside it. This is why a furnace can be a "muffle furnace" that operates with a "retort."

How They Work Together

In a typical controlled-atmosphere application, the process is simple:

- The material is placed inside the retort.

- The retort is sealed and purged with a specific gas or evacuated to create a vacuum.

- The entire retort is placed inside the muffle furnace to be heated.

This is why the terms are often conflated. You are using a muffle furnace to heat a retort.

Expanding the Context: Other Furnace Designs

Understanding the muffle/retort principle helps clarify how they compare to other furnace types that solve different problems.

Box Furnace vs. Tube Furnace

A standard muffle furnace is often a box furnace, ideal for processing objects that remain static in a single batch.

A tube furnace uses a cylindrical muffle/tube. This design is excellent for achieving high temperature uniformity and is often used for processing smaller samples or for continuous processes where material flows through the tube.

Hot Wall vs. Cold Wall Vacuum Furnaces

This is a critical distinction when a retort is used for vacuum applications.

A hot wall furnace is the classic design we've discussed: an external furnace (the muffle) heats the retort from the outside. This is simpler, but limits the maximum temperature and processing speed.

A cold wall furnace has heating elements inside the vacuum chamber (the retort), which itself is water-cooled. This allows for much higher temperatures, faster heating/cooling cycles, and cleaner vacuum conditions.

Understanding the Trade-offs

Choosing a furnace design is a matter of balancing performance, complexity, and cost.

Simplicity vs. Atmosphere Control

A basic muffle furnace used for heating in ambient air is simple, robust, and relatively inexpensive.

Introducing a retort to control the atmosphere adds significant complexity. You must manage gas supplies or vacuum pumps, and ensuring a perfect seal on the retort is critical to the process.

Batch vs. Continuous Throughput

Box-style muffle furnaces are designed for batch processing. Loading and unloading happen through a single door, which is simple but inefficient for high-volume production.

For continuous or high-volume needs, rotary furnaces or conveyor-style tube furnaces offer far greater energy efficiency and throughput.

Temperature Uniformity

A simple box muffle furnace may have temperature variations within its chamber.

For applications requiring precise uniformity, a three-zone tube furnace is superior, as it can fine-tune the temperature along the entire length of the sample. Similarly, cold wall vacuum furnaces generally offer better uniformity than hot wall designs.

Making the Right Choice for Your Application

Focus on your end goal, not the historical terminology.

- If your primary focus is general-purpose heating in air (e.g., ashing, tempering, binder burnout): A simple, cost-effective box muffle furnace is the correct tool.

- If your primary focus is processing under a specific gas (e.g., annealing, sintering): You need a furnace system that incorporates a sealed retort, which could be a box or tube furnace design.

- If your primary focus is high-temperature vacuum processing (e.g., brazing, degassing): A cold wall vacuum furnace offers superior performance, speed, and temperature capability.

- If your primary focus is high-volume, continuous processing of bulk materials: A rotary furnace will be significantly more efficient than a static batch furnace.

Understanding these fundamental design principles empowers you to look past confusing labels and select the furnace that truly meets your technical requirements.

Summary Table:

| Feature | Muffle Furnace | Retort Furnace |

|---|---|---|

| Primary Function | Creates insulated heating chamber | Provides sealed, controlled atmosphere |

| Heating Method | Indirect, via muffle lining | Indirect, via retort container |

| Atmosphere Control | Limited (e.g., ambient air) | High (vacuum, inert/reactive gases) |

| Common Applications | Ashing, tempering, binder burnout | Annealing, sintering, brazing |

| Complexity/Cost | Lower | Higher due to sealing and gas systems |

Need a high-temperature furnace tailored to your lab's unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your experimental requirements. Contact us today to discuss how we can enhance your process efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis