The core logic of vacuum coating lies in the precise deposition of multi-component, heat-resistant layers to fundamentally alter the surface properties of energy equipment. By creating a specialized barrier, this process decouples the surface's resistance requirements from the substrate's structural role, allowing components to withstand extreme heat and wear that raw materials alone cannot survive.

Vacuum coating enables the engineering of specific microstructures that provide exceptional hardness and thermal stability. This allows components like impellers to maintain structural integrity in aggressive environments, significantly extending service life beyond the capabilities of untreated materials.

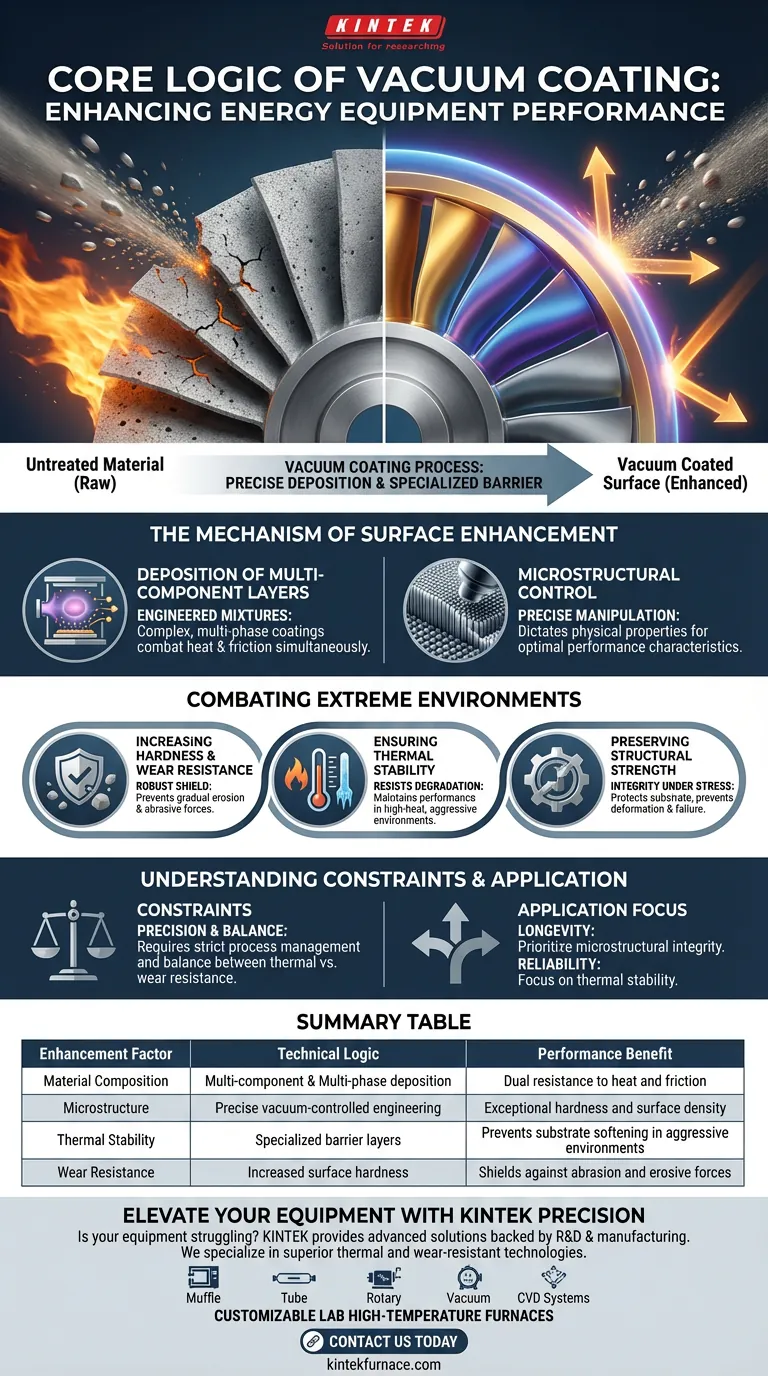

The Mechanism of Surface Enhancement

Deposition of Multi-Component Layers

The process utilizes vacuum technology to deposit complex, multi-component and multi-phase coatings onto component surfaces.

Rather than a simple uniform layer, these coatings are engineered mixtures designed specifically to combat heat and friction simultaneously.

Microstructural Control

A defining advantage of this process is the ability to exercise precise control over the coating's microstructure.

By manipulating how the material forms at the microscopic level, engineers can dictate the physical properties of the surface, ensuring optimal performance characteristics.

Combating Extreme Environments

Increasing Hardness and Wear Resistance

The primary logical function of the coating is to significantly improve material hardness.

This increased hardness provides a robust shield against abrasive forces, preventing the gradual erosion of parts during operation.

Ensuring Thermal Stability

Energy components often operate in high-temperature and aggressive environments, such as those found in flue gas extraction.

The coating provides essential thermal stability, allowing the underlying component to resist degradation and maintain performance despite intense heat.

Preserving Structural Strength

By protecting the surface from thermal and abrasive damage, the coating ensures the component maintains higher structural strength.

This is critical for parts like impellers, which must endure significant physical stress without deforming or failing.

Understanding the Constraints

The Necessity of Precision

The effectiveness of this logic relies entirely on the precise control of the microstructure.

If the deposition process is not strictly managed, the multi-phase coating may fail to achieve the required density or adhesion.

Environmental Specificity

The logic of vacuum coating is highly dependent on the specific aggressive environment the part faces.

A coating designed for thermal stability must be carefully balanced with the need for wear resistance; favoring one too heavily without precise engineering can compromise the other.

How to Apply This to Your Project

If your primary focus is Equipment Longevity: Prioritize coatings that demonstrate a proven ability to maintain microstructural integrity in aggressive, multi-phase environments to maximize service life.

If your primary focus is Structural Reliability: Ensure the coating selection focuses on thermal stability to prevent heat-induced softening of the substrate under heavy loads.

By leveraging precise microstructural control, vacuum coating transforms standard components into resilient assets capable of surviving the harshest industrial conditions.

Summary Table:

| Enhancement Factor | Technical Logic | Performance Benefit |

|---|---|---|

| Material Composition | Multi-component & Multi-phase deposition | Dual resistance to heat and friction |

| Microstructure | Precise vacuum-controlled engineering | Exceptional hardness and surface density |

| Thermal Stability | Specialized barrier layers | Prevents substrate softening in aggressive environments |

| Wear Resistance | Increased surface hardness | Shields against abrasion and erosive forces |

Elevate Your Equipment Performance with KINTEK Precision

Is your energy equipment struggling to survive aggressive industrial environments? KINTEK provides the advanced solution your project demands. Backed by expert R&D and world-class manufacturing, we specialize in enhancing component longevity through superior thermal and wear-resistant technologies.

Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temperature furnaces are fully customizable to meet your unique material engineering needs. Don't let thermal degradation or abrasive wear compromise your structural reliability.

Contact us today to consult with our experts and discover how KINTEK’s specialized systems can transform your standard components into resilient, high-performance assets.

Visual Guide

References

- А.M. Yalova, Nazarii Bondar. The problem of increasing the working resource of energy equipment details. DOI: 10.31498/2225-6733.49.2.2024.321349

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What protective functions does a circulating water cooling system provide during CVD? Secure Vacuum Integrity Today

- What is low temperature vapor deposition? A Guide to Coating Heat-Sensitive Materials

- What are some frequently asked questions about CVD coatings? Discover Key Benefits and Applications

- Why is mica preferred as a substrate for CVD growth of Mn3O4 nanosheets? Key Structural Advantages

- Why is a vacuum pump required for CVD graphene growth? Ensure High-Purity Material Synthesis

- When should PVD be chosen over CVD for thin-film deposition? Optimize Your Coating Process with Precision

- How do sodium-droplet eutectics (SODE) act as catalysts for MoS2 CVD growth? Achieve High-Quality Thin Film Synthesis

- What is the pressure range for CVD furnaces? Optimize Thin Film Deposition for Your Lab