At its core, the benefit of customizing a muffle furnace is to guarantee its performance aligns perfectly with a unique or highly specific application. Where a standard furnace might be adequate, a custom furnace is engineered to ensure optimal, repeatable results for a specialized process, significantly improving success rates in development and testing.

While standard muffle furnaces offer general-purpose utility, customization moves beyond a "one-size-fits-all" approach. It is an investment in precision, targeting the furnace's core attributes—chamber material, geometry, and controls—to solve a specific process challenge that an off-the-shelf unit cannot.

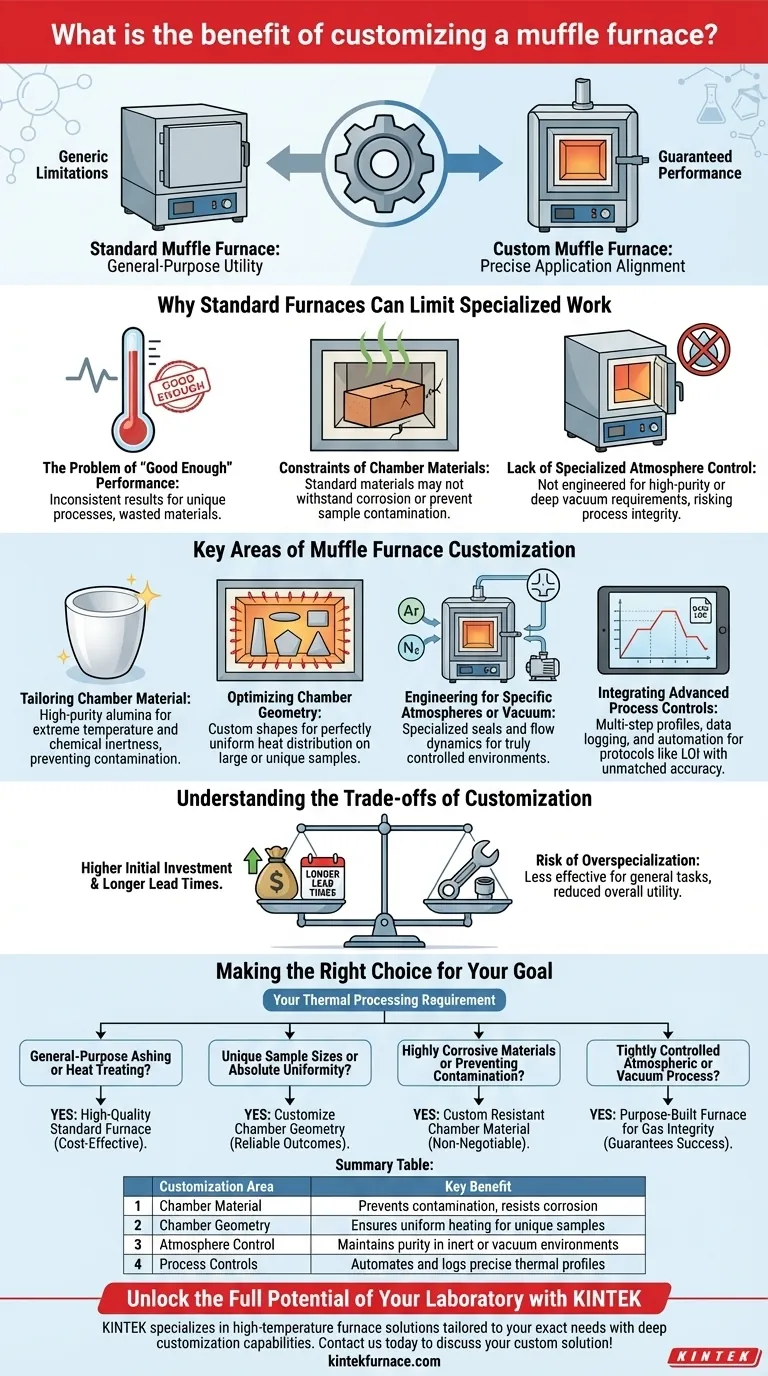

Why Standard Furnaces Can Limit Specialized Work

A standard muffle furnace is a versatile tool designed for a wide range of common applications like ashing, heat treating, and material testing. However, this versatility becomes a limitation when a process demands performance beyond its general-purpose design.

The Problem of "Good Enough" Performance

Standard furnaces offer good temperature control and uniformity, but they are built for common sample sizes and conditions. For unique or sensitive processes, "good enough" can lead to inconsistent results, failed tests, and wasted materials.

Constraints of Chamber Materials

The inner chamber, or muffle, in a standard furnace is typically made from a durable, all-purpose refractory material. This material may not withstand highly corrosive byproducts or prevent subtle chemical leaching that can contaminate sensitive samples.

Lack of Specialized Atmosphere Control

While some standard furnaces offer ports for introducing inert gas, they are not engineered for the rigorous demands of high-purity atmospheric control or deep vacuum applications. Leaks and inadequate flow design can compromise the entire process.

Key Areas of Muffle Furnace Customization

Customization allows you to re-engineer the furnace around your specific process, turning potential points of failure into guarantees of performance. The focus is on aligning the furnace's physical and digital components with your exact requirements.

Tailoring Chamber Material for Process Integrity

The muffle chamber can be built from specific materials to meet your needs. For example, high-purity alumina can be used for its extreme temperature capabilities and chemical inertness, preventing sample contamination. This also protects the heating elements from corrosive off-gassing.

Optimizing Chamber Geometry for Uniform Heating

If you are working with large, unconventionally shaped, or numerous samples, a custom chamber geometry is critical. The shape and size can be optimized to ensure perfectly uniform heat distribution, eliminating hot or cold spots that would compromise results in a standard chamber.

Engineering for Specific Atmospheres or Vacuum

For processes that are highly sensitive to oxygen, a custom furnace can be built with specialized seals, port designs, and flow dynamics. This ensures a truly controlled atmosphere, whether it's for an inert gas like argon or for maintaining a specific vacuum level.

Integrating Advanced Process Controls

Customization extends to the control system. You can specify multi-step thermal profiles, precise data logging, and integration with other lab systems. For protocols like Loss on Ignition (LOI), the furnace's digital controller can be programmed to automate the entire test with unmatched accuracy.

Understanding the Trade-offs of Customization

Choosing a custom solution requires a clear understanding of its implications. While powerful, it is not the right choice for every situation.

Higher Initial Investment

A furnace designed and built for a specific purpose will have a higher upfront cost than a mass-produced standard model. The engineering, specialized materials, and custom fabrication contribute to this increased investment.

Longer Lead Times

Unlike off-the-shelf units, a custom furnace requires a design, approval, and manufacturing cycle. This process can take weeks or months, which must be factored into your project timeline.

Risk of Overspecialization

A furnace tailored perfectly for one task may be less effective or even unusable for others. This can reduce the overall utility of the equipment in a lab with diverse and changing needs.

Making the Right Choice for Your Goal

The decision between a standard and a custom muffle furnace hinges entirely on the criticality and specificity of your thermal processing requirements.

- If your primary focus is general-purpose ashing or heat treating: A high-quality standard furnace is the most cost-effective and efficient solution.

- If your primary focus is processing unique sample sizes or achieving absolute temperature uniformity: Customizing the chamber geometry is essential for reliable and repeatable outcomes.

- If your primary focus is working with highly corrosive materials or preventing sample contamination: A custom muffle made from a specific chemically resistant material is non-negotiable.

- If your primary focus is a tightly controlled atmospheric or vacuum-based process: A purpose-built furnace engineered for gas integrity is the only way to guarantee success.

Ultimately, customizing a muffle furnace is an investment in eliminating process variables and achieving certainty in your results.

Summary Table:

| Customization Area | Key Benefit |

|---|---|

| Chamber Material | Prevents contamination, resists corrosion |

| Chamber Geometry | Ensures uniform heating for unique samples |

| Atmosphere Control | Maintains purity in inert or vacuum environments |

| Process Controls | Automates and logs precise thermal profiles |

Unlock the Full Potential of Your Laboratory with KINTEK

Struggling with inconsistent results from standard equipment? KINTEK specializes in high-temperature furnace solutions tailored to your exact needs. Leveraging exceptional R&D and in-house manufacturing, we offer advanced products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your furnace aligns perfectly with unique experimental requirements, boosting efficiency and accuracy.

Don't let limitations hold back your research—contact us today to discuss how we can design a custom solution for you!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production