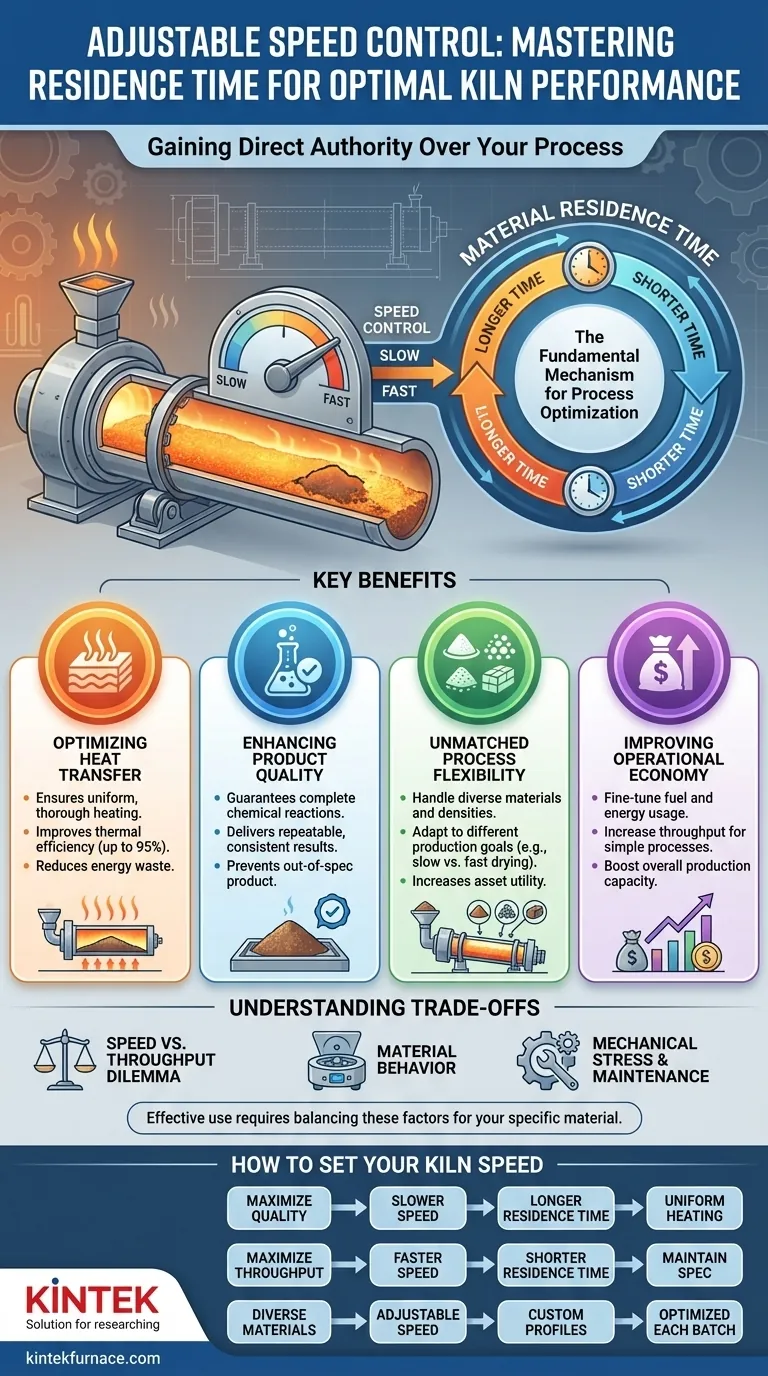

In short, adjustable speed control gives you direct authority over your process. It allows you to precisely manage how long material stays inside the kiln—known as residence time. This control is the key to optimizing heat transfer, ensuring chemical reactions are complete, and adapting the kiln to handle a wide variety of materials and production goals.

The ability to adjust a rotary kiln's speed is not just about flexibility; it is the fundamental mechanism for controlling material residence time. This control directly dictates heat transfer efficiency, reaction completion, and ultimately, the quality and consistency of your final product.

The Core Principle: Mastering Residence Time

Adjustable speed, often achieved through a frequency conversion drive, is a simple concept with profound implications for your operation. The entire benefit hinges on its direct relationship with material residence time.

What is Residence Time?

Residence time is the average duration a particle of material spends traveling from the kiln's feed end to its discharge end.

It is one of the most critical variables in any thermal process, alongside temperature and atmosphere.

How Speed Controls Residence Time

The relationship is straightforward and inverse:

- Slower rotation speed means the material tumbles and advances more slowly, resulting in a longer residence time.

- Faster rotation speed moves the material through the kiln more quickly, resulting in a shorter residence time.

Why This Matters for Your Process

Different thermal processes have different requirements. A process that is perfectly optimized for one residence time may be inefficient or ineffective at another. Adjustable speed allows you to dial in the exact conditions you need.

Key Benefits of Precise Speed Control

Controlling residence time is not an academic exercise; it translates directly into tangible operational advantages that impact efficiency, quality, and your bottom line.

Optimizing Heat Transfer and Thermal Efficiency

To heat material thoroughly and evenly, energy must have sufficient time to transfer from the heat source (burner or elements) and penetrate the material bed.

A longer residence time allows for more complete heat absorption, which improves thermal efficiency (up to 95% in some designs) and reduces wasted energy. This also promotes uniform heating, preventing hot spots or under-processed cold spots in the material.

Enhancing Product Quality and Consistency

Many industrial applications, from mineral calcination to waste incineration, involve specific chemical reactions that require a certain amount of time at temperature to complete.

If residence time is too short, reactions may be incomplete, leading to a low-quality or out-of-spec product. By precisely controlling the speed, you can guarantee that every particle gets the required processing time, ensuring repeatable, high-quality results cycle after cycle.

Gaining Unmatched Process Flexibility

A fixed-speed kiln is a one-trick pony. An adjustable-speed kiln is a versatile tool.

This flexibility allows you to use a single kiln to process various materials with different densities, particle sizes, or moisture contents. You can run a slow, delicate process one day and a high-speed drying cycle the next, dramatically increasing the asset's utility.

Improving Operational Economy

Optimized processes are more economical. By fine-tuning the kiln speed, you ensure you are not using more fuel or energy than necessary.

Furthermore, for simple processes like drying, the ability to increase speed allows for higher throughput, processing more material per hour and increasing overall production capacity without investing in new equipment.

Understanding the Trade-offs and Considerations

While invaluable, adjustable speed control is not a magic bullet. Effective use requires understanding the trade-offs involved.

The Speed vs. Throughput Dilemma

There is a fundamental balance to be struck. A slower speed almost always improves thermal efficiency and reaction completion but necessarily reduces the kiln's throughput (tons per hour). The goal is to find the fastest possible speed that still meets your quality specifications.

Material Behavior and Bed Dynamics

Kiln speed directly affects how the material tumbles. Too slow, and the material bed may slide instead of tumble, leading to poor mixing. Too fast, and the material may begin to centrifuge, sticking to the kiln wall and preventing proper heat exposure. The optimal speed range is dependent on the material's specific characteristics.

Mechanical Stress and Maintenance

Modern variable frequency drives (VFDs) are extremely reliable. However, consistently operating at the upper limits of the kiln's designed speed can increase long-term wear on mechanical components like the main gear, pinion, riding rings (tires), and trunnion rollers.

How to Set Your Kiln Speed

The ideal speed is always a function of your primary operational goal. Use these principles as your guide.

- If your primary focus is maximizing product quality and reaction completion: Opt for a slower rotation speed to increase residence time and ensure uniform, thorough heating.

- If your primary focus is maximizing throughput for a simple process (like drying): Utilize a faster rotation speed to reduce residence time, as long as product quality remains within specification.

- If your primary focus is processing diverse or variable feed materials: Leverage adjustable speed to create custom operational profiles for each material type, optimizing the process for each batch.

Ultimately, adjustable speed control transforms the rotary kiln from a fixed piece of equipment into a dynamic and highly precise processing tool.

Summary Table:

| Benefit | Description |

|---|---|

| Optimized Heat Transfer | Improves thermal efficiency and uniform heating by controlling residence time. |

| Enhanced Product Quality | Ensures complete chemical reactions and consistent, high-quality output. |

| Process Flexibility | Allows handling of diverse materials and production goals with ease. |

| Operational Economy | Reduces energy waste and increases throughput for cost savings. |

Unlock the full potential of your thermal processes with KINTEK's advanced rotary kiln solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with customizable high-temperature furnace systems, including Rotary Furnaces, to precisely meet your unique experimental needs. Contact us today to discuss how our tailored solutions can boost your efficiency and product quality!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing