The primary advantage of computer-controlled processes in vacuum furnaces is the ability to achieve perfect, digitally-enforced repeatability. This transforms heat treatment from a manual craft subject to human error into a precise, reliable, and data-driven manufacturing science. Every critical parameter—from temperature ramp rates to vacuum levels—is executed identically for every batch.

The core value of computer control is not just automation; it is the guarantee of process integrity. This ensures that every part meets its exact metallurgical specification, which is non-negotiable for high-performance applications.

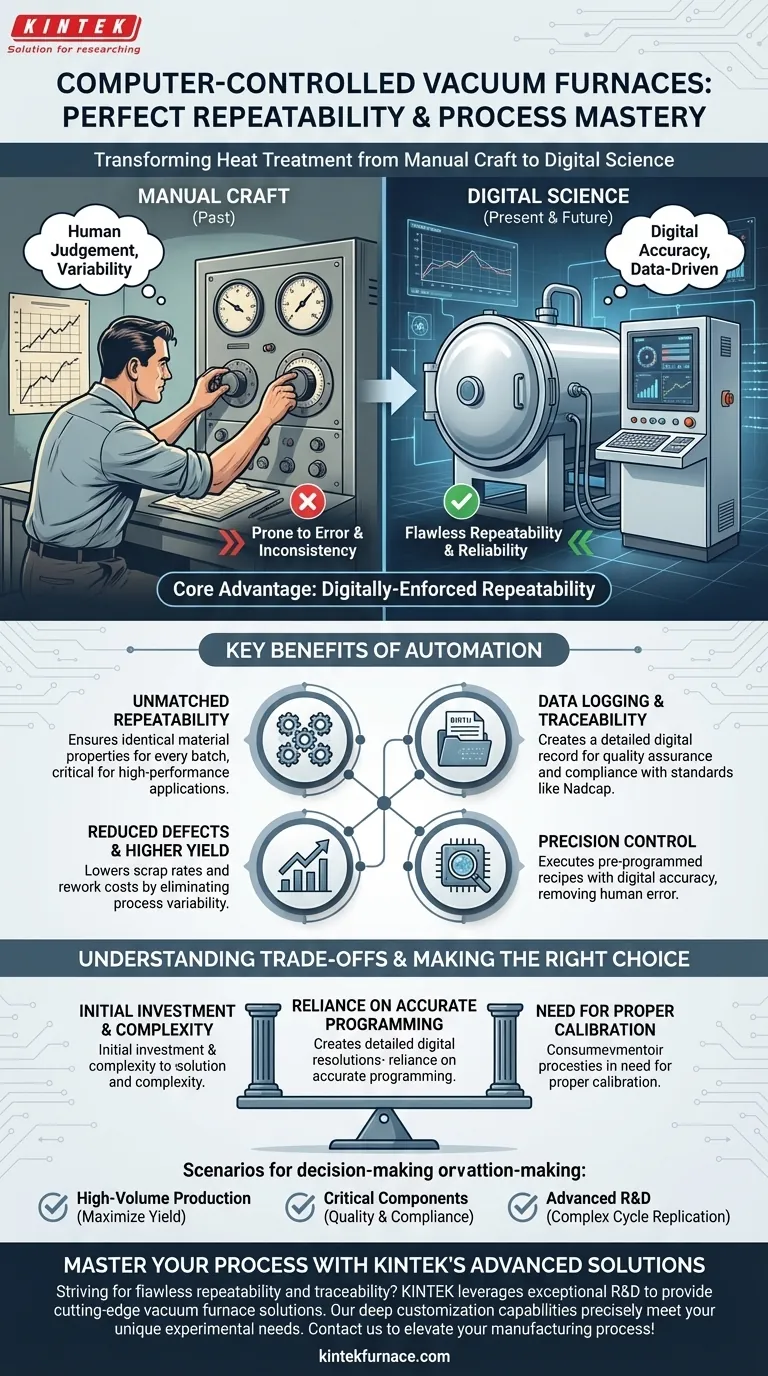

The Shift from Manual Art to Digital Science

Historically, operating a furnace required a skilled technician to manually interpret charts and adjust dials. While effective, this process was inherently prone to small variations that could have major impacts on the final product.

The Problem with Manual Operation

Manual control introduces variability. Even the most experienced operator cannot perfectly replicate a complex heating and cooling cycle every single time.

Slight differences in soak times, temperature overshoots, or cooling rates can alter a material's microstructure. This leads to inconsistent part quality, hidden defects, and unpredictable performance.

How Computer Control Delivers Precision

A computer-controlled system executes a pre-programmed "recipe" with digital accuracy. It follows the defined time, temperature, and pressure parameters without deviation.

This system continuously monitors furnace conditions via sensors and makes instantaneous, micro-adjustments to ensure the process stays exactly on track. This removes human judgment and variability from the equation entirely.

Key Benefits of an Automated Process

Automating a vacuum furnace process delivers tangible improvements in quality, efficiency, and oversight.

Unmatched Repeatability and Consistency

This is the foundational benefit. By executing the same thermal cycle flawlessly every time, computer control ensures that the material properties of the first part are identical to the thousandth.

This level of consistency is critical in industries like aerospace, medical, and automotive, where component failure is not an option.

Data Logging and Process Traceability

Every second of the heat treatment cycle is recorded. This creates a detailed digital record, or "birth certificate," for each batch of parts.

This data is invaluable for quality assurance, process validation, and meeting stringent industry certification standards like Nadcap. If a problem ever arises, the data log allows for precise root cause analysis.

Reduced Defects and Higher Yield

Process consistency directly translates to fewer rejected parts. By eliminating the variations that cause defects, manufacturers see a significant increase in production yield.

This reduces material waste, lowers rework costs, and increases overall operational efficiency.

Understanding the Trade-offs

While powerful, computer control is not a magic bullet. It introduces its own set of considerations that must be managed.

Initial Investment and Complexity

Computer-controlled vacuum furnaces represent a higher upfront capital investment compared to simpler, manually operated units. The control systems and software add to the initial cost.

Reliance on Accurate Programming

The system is only as good as the recipe it is given. An incorrectly programmed cycle will be executed with perfect precision, leading to a consistently bad result. Expertise is required to develop and validate these treatment recipes.

Need for Proper Calibration

The system's accuracy depends entirely on its sensors (thermocouples, pressure gauges). A regular and diligent calibration schedule is essential to ensure the computer is acting on correct information.

Making the Right Choice for Your Goal

The decision to invest in computer control depends on your specific manufacturing priorities.

- If your primary focus is high-volume production: The unmatched repeatability will maximize your yield, reduce scrap rates, and deliver a clear return on investment.

- If your primary focus is critical components (e.g., aerospace, medical): The data logging and process traceability are non-negotiable for meeting quality and certification requirements.

- If your primary focus is advanced materials R&D: The ability to design, execute, and perfectly replicate complex thermal cycles is essential for developing and testing new alloys.

Ultimately, computer control empowers you to master the heat treatment process with absolute certainty.

Summary Table:

| Benefit | Description |

|---|---|

| Unmatched Repeatability | Ensures identical material properties for every batch, critical for high-performance applications. |

| Data Logging & Traceability | Provides detailed digital records for quality assurance and compliance with standards like Nadcap. |

| Reduced Defects & Higher Yield | Lowers scrap rates and rework costs by eliminating process variability. |

| Precision Control | Executes pre-programmed recipes with digital accuracy, removing human error. |

Master Your Heat Treatment Process with KINTEK's Advanced Solutions

Are you striving for flawless repeatability and traceability in your high-temperature applications? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge vacuum furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're in aerospace, medical, or R&D, our computer-controlled systems ensure consistent quality and efficiency.

Contact us today to discuss how we can tailor a solution for your specific requirements and elevate your manufacturing process!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Induction Melting Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment