In essence, a retort furnace is a high-temperature oven with a critical design feature: it uses a sealed, gas-tight container (the "retort") to heat materials. This separates the workload from the furnace's heating elements and the outside air, allowing for precise control over both the temperature and the atmospheric gases surrounding the material during processing.

The core purpose of a retort furnace is not just to heat material, but to do so within a perfectly controlled environment. This isolation prevents unwanted chemical reactions, like oxidation, enabling heat treatment processes that would be impossible in a standard, open-air furnace.

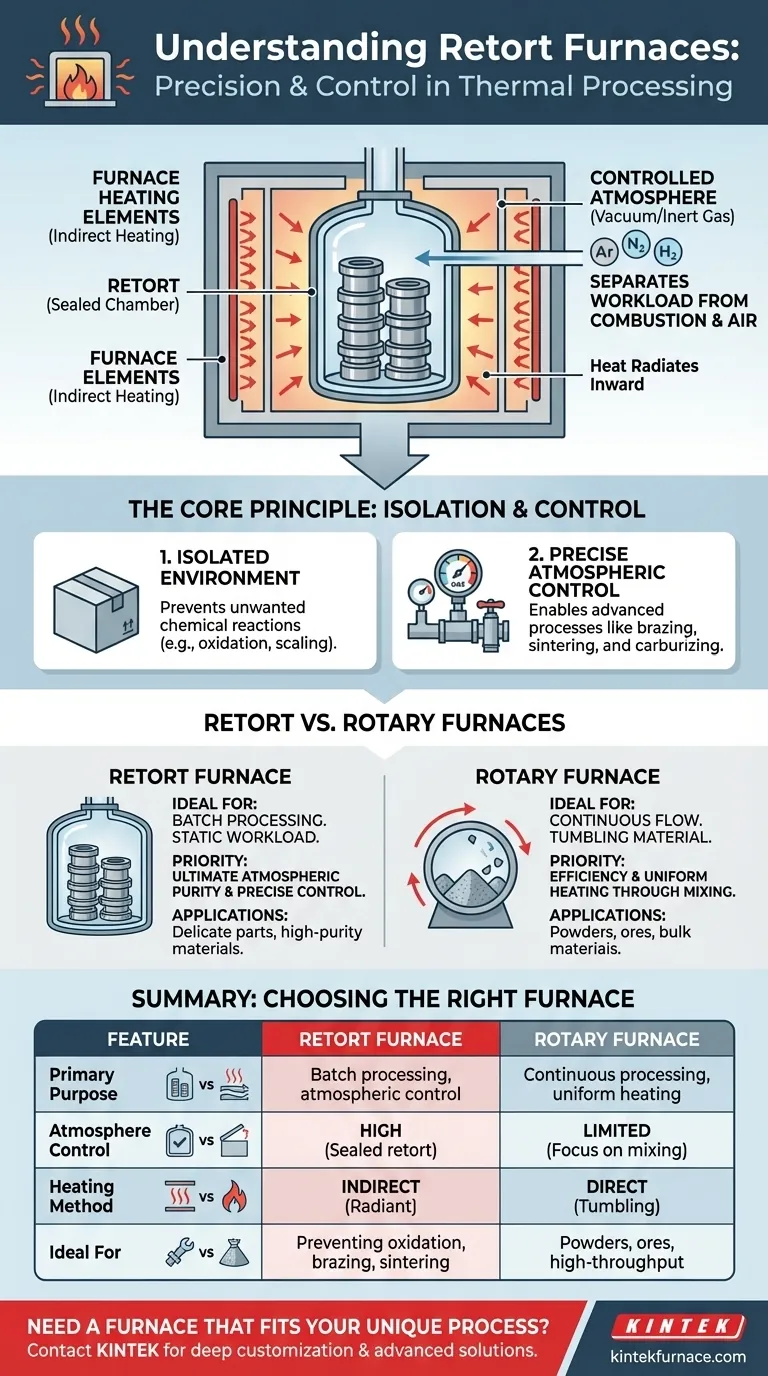

The Core Principle: Isolation and Control

The functionality of a retort furnace is defined by its ability to create an isolated processing environment. This is achieved through two key design elements: the retort itself and the method of indirect heating.

What is the "Retort"?

The "retort" is the heart of the system. It is a sealed chamber or container, typically made from high-temperature resistant steel or ceramic, that holds the material being processed.

This chamber is placed inside the larger furnace structure. Its gas-tight design is what allows a specific atmosphere—be it a vacuum, an inert gas like argon, or a reactive gas like hydrogen—to be introduced and maintained.

The Logic of Indirect Heating

In a retort furnace, the heating elements warm the retort from the outside. The retort, in turn, radiates heat inward to process the material.

This indirect heating is crucial. It ensures the material is never exposed to the combustion byproducts or electrical elements of the furnace itself, preventing contamination and ensuring a clean processing environment.

The Power of Atmospheric Control

The ability to manipulate the atmosphere is the retort furnace's primary advantage. By removing oxygen, you can prevent scaling and oxidation on metal surfaces.

Furthermore, you can introduce specific gases to actively change the material's properties. This enables advanced processes like brazing, sintering, and carburizing, which depend on specific chemical interactions at high temperatures.

Understanding the Trade-offs: Retort vs. Rotary Furnaces

It is common to confuse retort furnaces with rotary furnaces, as both are used for specialized thermal processing. However, they solve fundamentally different problems.

Retort Furnace: Precision for Batches

A retort furnace is ideal for batch processing, where ultimate atmospheric purity and precise control are the main goals. The workload is static, ensuring that delicate parts are not damaged.

The focus is on achieving specific material properties in a highly controlled, high-purity environment.

Rotary Furnace: Efficiency for Continuous Flow

A rotary furnace, or rotary tube furnace, is designed for the continuous processing of loose materials like powders, ores, or pellets. Its defining feature is a rotating cylindrical chamber.

The primary benefit here is uniform heating through mixing. As the tube rotates, it tumbles the material, constantly exposing new surfaces to the heat source. The goal is high throughput and thermal consistency for bulk materials, not necessarily atmospheric purity.

The Key Distinction

Choose a retort furnace when your priority is perfect atmospheric control for a static batch. Choose a rotary furnace when your priority is efficiently and uniformly heating a moving stream of bulk material.

Making the Right Choice for Your Process

Selecting the correct furnace technology hinges on the primary goal of your thermal process.

- If your primary focus is material purity and preventing oxidation in a batch process: The isolated, controlled atmosphere of a retort furnace is essential.

- If your primary focus is uniformly heating large volumes of loose material in a continuous flow: A rotary furnace is designed specifically for this kind of throughput and mixing efficiency.

- If your primary focus is simple heat treatment where atmospheric exposure is not a concern: A standard, non-retort furnace may be the most cost-effective solution.

Understanding this fundamental difference between isolation for purity and motion for uniformity is the key to selecting the correct thermal processing equipment.

Summary Table:

| Feature | Retort Furnace | Rotary Furnace |

|---|---|---|

| Primary Purpose | Batch processing with precise atmospheric control | Continuous processing for uniform heating of bulk materials |

| Atmosphere Control | High (sealed retort for vacuum/inert gases) | Limited (focus on mixing, not purity) |

| Heating Method | Indirect (heats retort, which radiates inward) | Direct (rotating chamber tumbles material) |

| Ideal For | Preventing oxidation, brazing, sintering | Powders, ores, high-throughput applications |

Need a furnace that fits your unique process? At KINTEK, we specialize in advanced high-temperature solutions tailored to your needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your experimental requirements. Whether you're in materials science, metallurgy, or research, contact us today to enhance your lab's efficiency and achieve superior results! Contact us now for a consultation.

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.