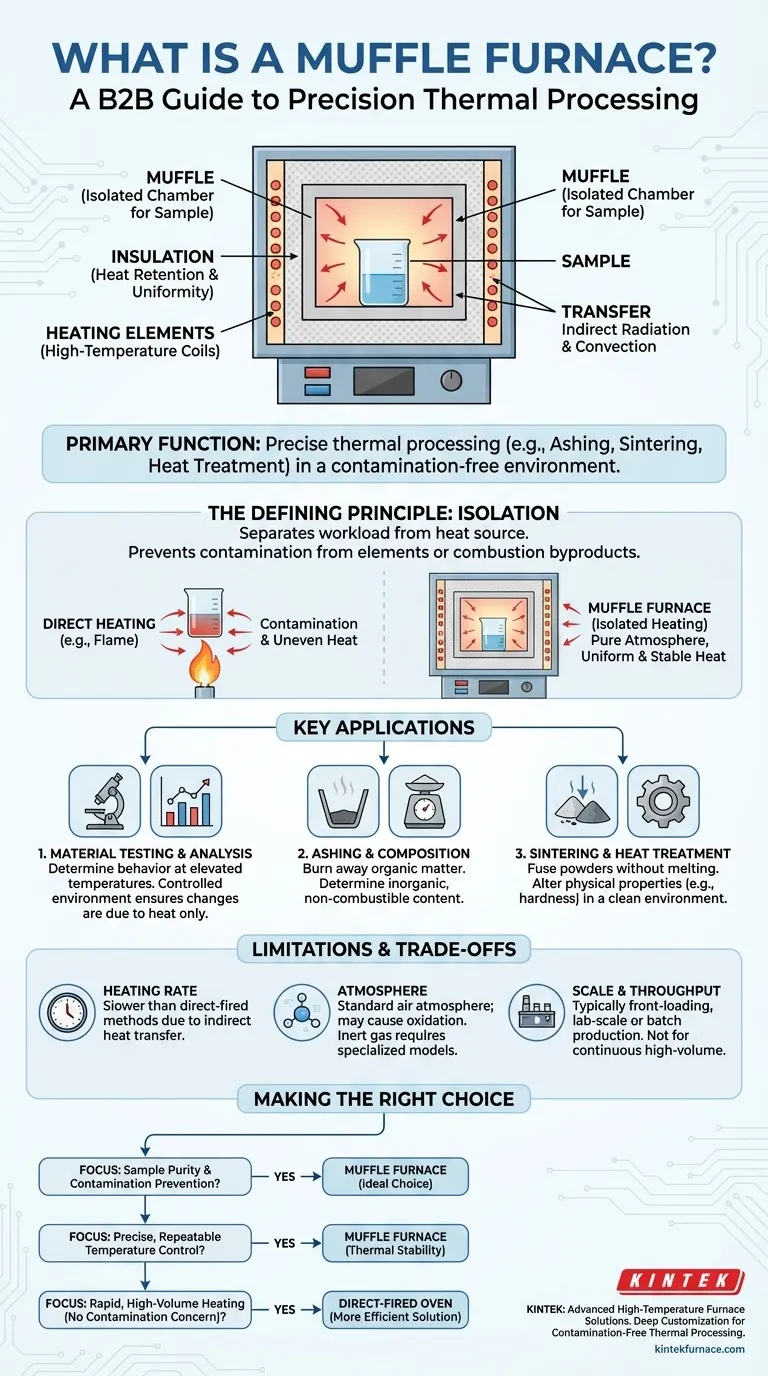

At its core, a muffle furnace is a high-temperature oven that heats materials within an isolated chamber. Its primary function is to perform precise thermal processing—such as ashing, sintering, or heat treatment—without allowing the material to come into direct contact with the heating elements or any contaminants from combustion.

The defining characteristic of a muffle furnace is not just its ability to reach high temperatures, but its use of a "muffle"—an internal chamber that separates the sample from the heat source. This isolation is the key to preventing contamination and ensuring process purity.

The Defining Principle: Isolation

A muffle furnace is engineered around a single, critical concept: separating the workload from the source of heat. This design directly enables its most important capabilities.

What “Muffle” Truly Means

The term muffle refers to the enclosed, separate chamber where the material is placed. Think of it as a box-within-a-box.

The outer box contains the heating elements, which are typically high-temperature electrical coils embedded in thermally efficient insulation. The inner box, or muffle, holds the sample.

Heat is transferred from the outer chamber to the inner chamber through radiation or convection, but the sample itself is never exposed to the raw heating elements.

How It Achieves High, Stable Temperatures

The furnace walls are constructed from dense insulating material. This design serves two purposes.

First, it prevents heat from escaping, which makes the furnace highly energy-efficient and allows it to reach and maintain extreme temperatures, often exceeding 1000°C.

Second, the insulation and separated chamber create a uniform thermal environment, allowing for the precise temperature control required for sensitive scientific and industrial processes.

The Importance of a Pure Atmosphere

By isolating the sample, a muffle furnace prevents contamination that would occur with direct heating methods.

In electric models, this prevents any potential interaction with the heating coils. In fuel-fired versions, it crucially separates the sample from combustion gases, fuel, and other chemical byproducts. This ensures the material's properties are altered only by heat, not by unintended chemical reactions.

Key Applications in Science and Industry

The unique capabilities of a muffle furnace make it indispensable for processes where both high heat and high purity are required.

Material Testing and Analysis

Laboratories use muffle furnaces to determine how materials behave at elevated temperatures. The controlled environment ensures that any observed changes in the material's characteristics are a direct result of the heat applied.

Ashing and Compositional Analysis

Ashing is a common technique used to determine the inorganic, non-combustible content of a sample.

The furnace heats the sample to a temperature where all organic matter burns away, leaving only the "ash" (inorganic components) behind for weighing and analysis.

Sintering and Heat Treatment

In materials science and manufacturing, sintering uses heat to fuse powders into a solid mass without melting them.

Heat treatment involves carefully heating and cooling metals to alter their physical properties, such as increasing hardness or ductility. A muffle furnace provides the clean, controlled environment essential for these processes.

Understanding the Trade-offs and Limitations

While highly effective, a muffle furnace is not the right tool for every high-temperature application. Understanding its limitations is key to using it correctly.

Heating Rate vs. Direct Heating

Because the heat is transferred indirectly, a muffle furnace may heat a sample more slowly than a direct-fired kiln or torch where a flame makes direct contact with the material.

Atmosphere is Not Inherently Inert

A standard muffle furnace operates with a normal air atmosphere. While it prevents contamination from the heat source, it does not prevent oxidation. To work in an oxygen-free or inert gas environment (like argon or nitrogen), a specialized furnace with gas-purging capabilities is required.

Scale and Throughput

Muffle furnaces are typically front-loading, box-type ovens designed for lab-scale or batch production. They are not generally suited for high-volume, continuous industrial processes that might be better served by a larger tunnel kiln.

Making the Right Choice for Your Process

Use the furnace’s core principle of isolation to guide your decision.

- If your primary focus is sample purity and preventing contamination: The isolated chamber of a muffle furnace is its most critical advantage, making it the ideal choice.

- If your primary focus is precise, repeatable temperature control for sensitive materials: The combination of insulation and indirect heating provides the thermal stability you require.

- If your primary focus is simply rapid, high-volume heating without concern for contamination: A less complex direct-fired oven or kiln may be a more efficient and cost-effective solution.

Understanding this fundamental design principle empowers you to select the right thermal process for your specific goal.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | Precise thermal processing (e.g., ashing, sintering) in an isolated chamber to prevent contamination |

| Key Features | Isolation of sample, high-temperature capability (often >1000°C), precise temperature control, uniform heating |

| Common Applications | Material testing, ashing for compositional analysis, sintering, heat treatment in labs and manufacturing |

| Limitations | Slower heating rates than direct-fired methods, standard air atmosphere (may cause oxidation), not suited for high-volume continuous processes |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental needs for contamination-free, precise thermal processing. Contact us today to discuss how our furnaces can enhance your research and industrial applications!

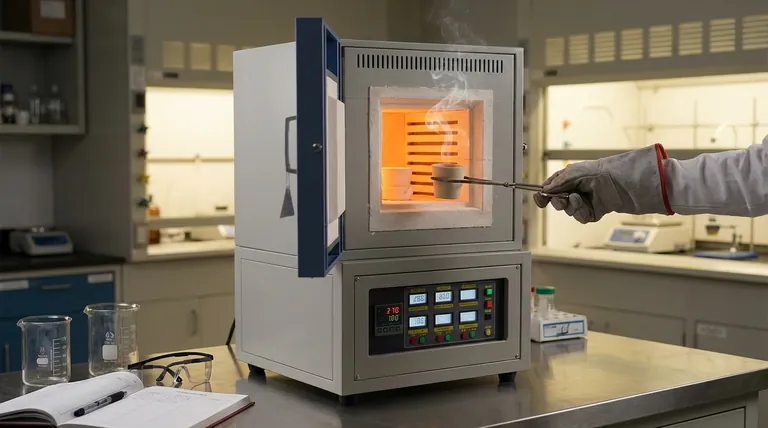

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity