At its core, a dental porcelain furnace is a highly specialized, high-temperature oven used in dental laboratories to fabricate ceramic dental restorations. Its primary purpose is to heat dental porcelain materials through a process called sintering, which transforms them from a fragile powder or block into a hard, durable, and aesthetically pleasing final state for use in crowns, veneers, and bridges.

A porcelain furnace is not merely an oven; it is a precision instrument that enables dental technicians to control the transformation of ceramic materials. This control is the critical factor in creating dental restorations that are not only strong and durable but also perfectly match the color, translucency, and texture of natural teeth.

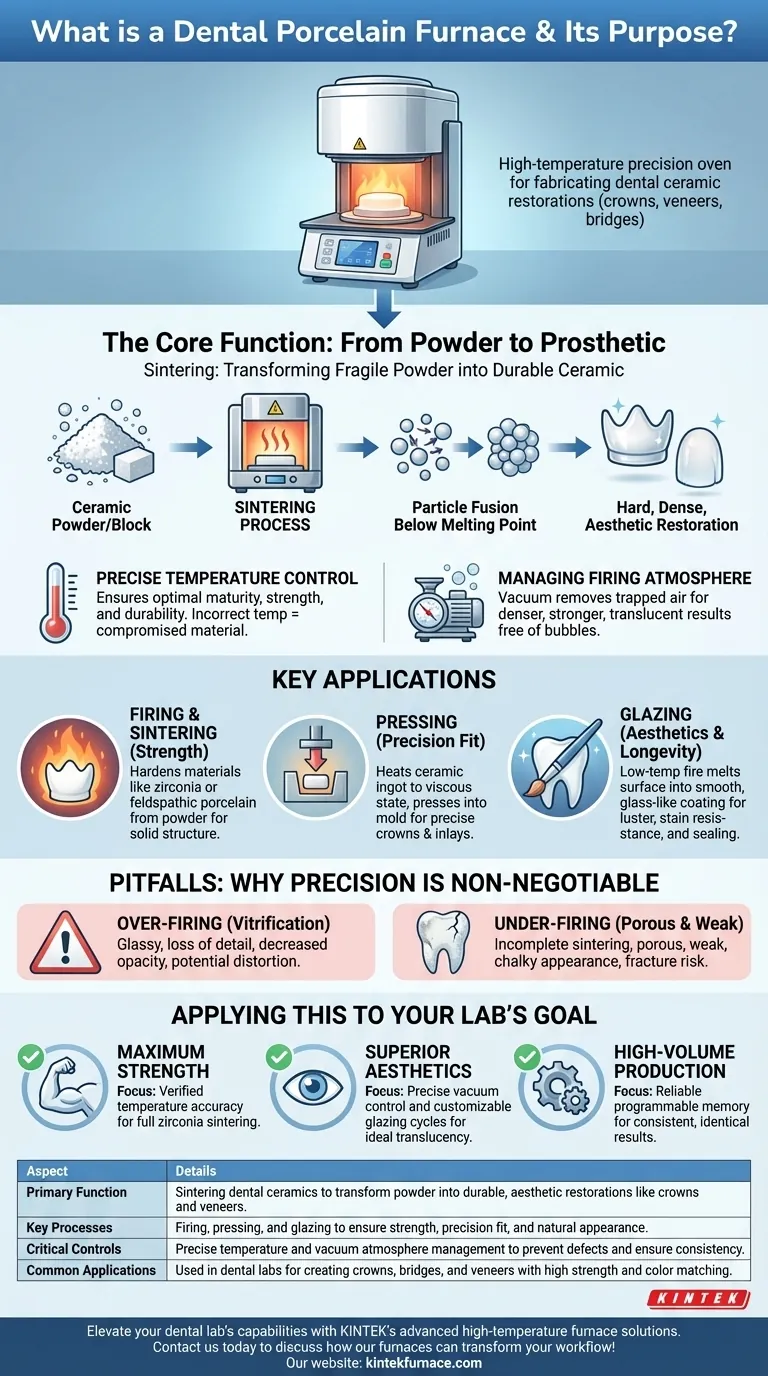

The Core Function: From Powder to Prosthetic

A porcelain furnace’s main job is to provide a perfectly controlled environment for the chemical and physical transformation of dental ceramics. This process is fundamentally about managing heat and atmosphere to achieve a specific outcome.

What is Sintering?

Sintering is the central process that occurs inside the furnace. It involves heating the compacted ceramic particles to a high temperature just below their melting point.

Instead of melting, the particles fuse together at their contact points. This fusion eliminates the pores between particles, increasing the material's density, strength, and translucency.

The Importance of Precise Temperature Control

The final strength and durability of a dental restoration are directly tied to the furnace’s ability to follow a precise temperature program. Ramping up the heat too quickly or reaching an incorrect peak temperature can compromise the material.

Proper temperature management ensures that the ceramic reaches optimal maturity, resulting in a restoration that can withstand the forces of chewing while maintaining its structure.

Managing the Firing Atmosphere

Modern dental furnaces also control the atmosphere within the firing chamber, often by creating a vacuum.

Pulling a vacuum during the initial stages of heating removes trapped air from the porcelain, resulting in a denser, stronger, and more translucent restoration free of bubbles or imperfections.

Key Applications in Dental Fabrication

The furnace is a versatile tool used at several critical stages of creating a dental prosthetic. Each application uses a different firing program to achieve a specific goal.

Firing and Sintering for Strength

This is the fundamental process used to harden ceramic materials like zirconia or feldspathic porcelain. Technicians build up the restoration from powder and then fire it to create a strong, solid structure.

Pressing for Precision Fit

For "pressable" ceramics, the furnace heats a ceramic ingot until it becomes viscous. It then uses pressure to press the softened material into a mold, creating incredibly precise restorations like full crowns and inlays.

Glazing for Aesthetics and Longevity

After the restoration's shape and color are finalized, a final, lower-temperature "glaze fire" is performed. This melts a thin surface layer into a smooth, glass-like coating.

This glaze not only creates a natural-looking luster but also seals the restoration, making it stronger, less abrasive to opposing teeth, and more resistant to staining.

Understanding the Pitfalls: Why Precision is Non-Negotiable

The success of a dental restoration depends entirely on the precision of the firing cycle. Minor deviations can lead to catastrophic failures, making the furnace operator's skill and the equipment's reliability paramount.

The Risk of Over-Firing

If the temperature is too high or held for too long, the porcelain can begin to vitrify, or turn glassy.

This results in a loss of surface detail, a decrease in opacity (making the color appear off), and potential slumping or distortion of the restoration's shape.

The Danger of Under-Firing

An incomplete firing cycle leaves the restoration porous and weak. The ceramic particles will not have fully sintered, making the final crown or bridge susceptible to fracture under normal use.

Under-fired porcelain also appears chalky and opaque, failing to meet the aesthetic requirements for a natural-looking tooth.

The Challenge of Color Matching

The final shade of a restoration is highly dependent on the firing process. Different firing programs can produce different results even with the same porcelain powder. Achieving a perfect match to the patient's natural dentition requires consistent and repeatable furnace performance.

Applying This to Your Laboratory's Goal

The way you use a porcelain furnace depends on the specific priorities of your dental laboratory or clinic.

- If your primary focus is maximum strength and durability: Prioritize furnaces with verified temperature accuracy and programs designed for full sintering of high-strength materials like zirconia.

- If your primary focus is superior aesthetics: Emphasize precise vacuum control and customizable glazing cycles to achieve ideal translucency and surface texture.

- If your primary focus is high-volume, consistent production: Invest in a furnace with reliable, programmable memory for storing dozens of firing cycles to ensure every restoration is processed identically.

Ultimately, the dental porcelain furnace is the critical link that turns raw material and technical skill into a successful, long-lasting dental restoration.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Function | Sintering dental ceramics to transform powder into durable, aesthetic restorations like crowns and veneers. |

| Key Processes | Firing, pressing, and glazing to ensure strength, precision fit, and natural appearance. |

| Critical Controls | Precise temperature and vacuum atmosphere management to prevent defects and ensure consistency. |

| Common Applications | Used in dental labs for creating crowns, bridges, and veneers with high strength and color matching. |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide dental laboratories with precision tools like Muffle, Tube, and Vacuum Furnaces, along with strong deep customization to meet your unique restoration needs. Achieve superior strength, aesthetics, and consistency in every prosthetic—contact us today to discuss how our furnaces can transform your workflow!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations