In short, vacuum heat treatment can perform nearly all conventional heat treatment processes. This includes critical operations like quenching, annealing, tempering, and case hardening methods such as carburizing and nitriding. These processes are all executed within a controlled, contamination-free environment, which is the primary reason for choosing this technology.

The fundamental advantage of vacuum heat treatment is not just the variety of processes it can perform, but its ability to eliminate atmospheric contamination. This ensures a clean, bright surface finish and highly uniform material properties that are often impossible to achieve with traditional atmosphere-based methods.

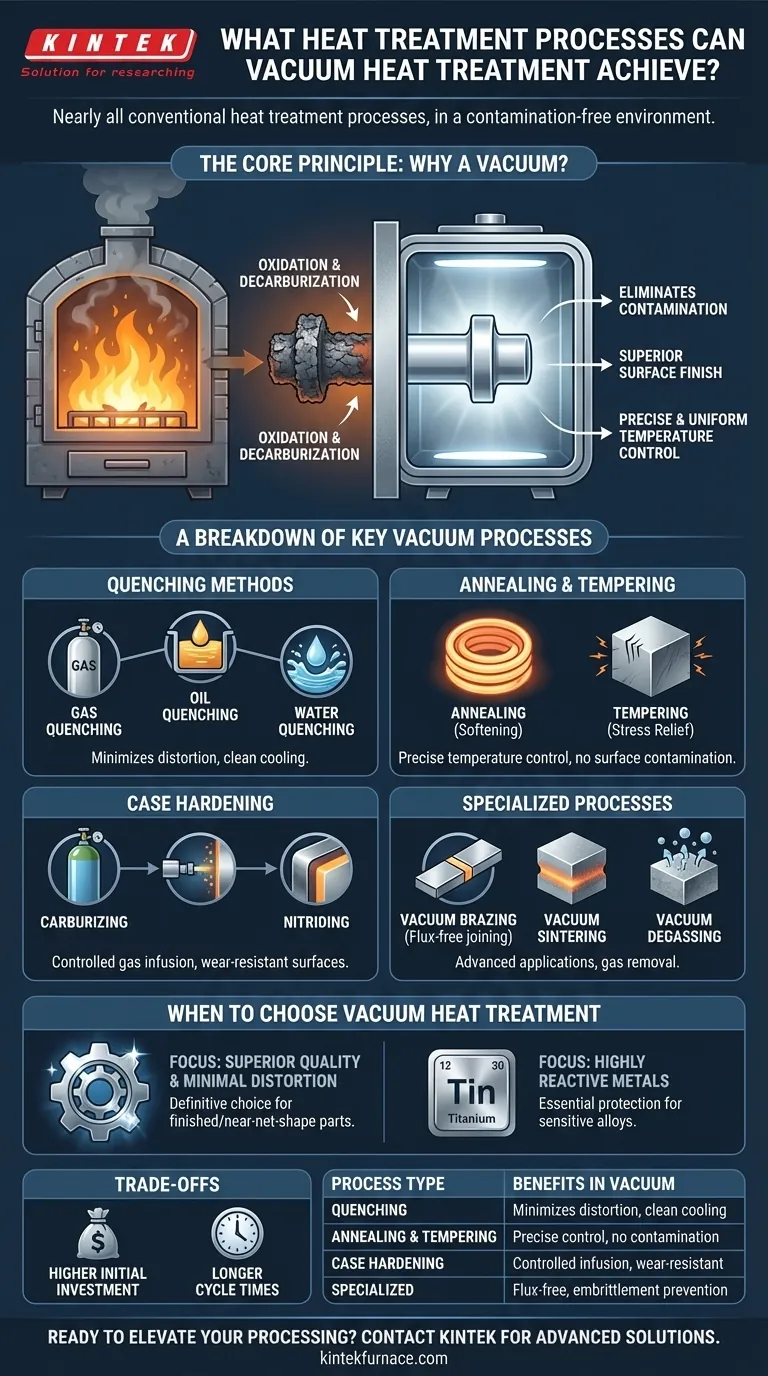

The Core Principle: Why a Vacuum?

The decision to use a vacuum furnace centers on achieving a level of quality and control that is difficult with other methods. The vacuum itself is not the treatment; it is the perfect environment for the treatment to occur.

Eliminating Oxidation and Decarburization

In a traditional furnace, ambient air reacts with the hot metal surface. This causes oxidation (scaling) and can lead to decarburization (the loss of carbon from the surface of steel), which softens the material.

By removing the air, a vacuum furnace prevents these detrimental reactions. This is the single most important benefit of the technology.

Ensuring a Superior Surface Finish

Because there is no oxidation, parts emerge from a vacuum furnace with a clean, bright, and often shiny surface. This significantly reduces or eliminates the need for post-treatment cleaning operations like sandblasting or chemical pickling, saving time and cost.

Precise and Uniform Temperature Control

Heating in a vacuum occurs primarily through radiation. This allows for extremely precise and uniform temperature control across the entire part, minimizing distortion and ensuring consistent metallurgical properties.

A Breakdown of Key Vacuum Processes

A vacuum furnace is a versatile tool capable of executing a wide range of thermal processes with high precision.

Quenching Methods

Quenching (rapid cooling) is critical for hardening steel. Vacuum furnaces can perform several types of quenching by backfilling the sealed chamber with a specific medium.

- Gas Quenching: High-pressure inert gas (like nitrogen or argon) is used for a controlled, clean quench. This is common for tool steels and alloys where distortion must be minimized.

- Oil Quenching: The heated part is lowered into an integrated, sealed oil bath. This provides a faster cooling rate than gas for alloys that require it.

- Water Quenching: Similar to oil quenching, but uses water for an even more aggressive quench. This is less common due to the high risk of distortion.

Annealing and Tempering

Annealing (softening) and tempering (reducing brittleness after hardening) both benefit from the precise temperature control and soak times possible in a vacuum. The clean environment ensures the material's surface chemistry is unaltered.

Case Hardening (Carburizing and Nitriding)

Case hardening creates a hard, wear-resistant surface on a softer core. While it seems counterintuitive, this is also done in a vacuum furnace.

The process starts in a vacuum to clean and heat the part. Then, a small, precisely controlled amount of a reactive gas (e.g., acetylene for carburizing or ammonia for nitriding) is introduced at low pressure to infuse the surface with carbon or nitrogen.

Specialized High-Temperature Processes

The clean, controlled environment of a vacuum furnace is ideal for advanced applications like:

- Vacuum Brazing: Joining materials using a filler metal without using flux, resulting in an extremely strong and clean joint.

- Vacuum Sintering: Fusing powdered materials together to create a solid object.

- Vacuum Degassing: Removing trapped gases like hydrogen from a material, which can prevent embrittlement.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the universal solution for every application. Objectivity requires acknowledging its limitations.

Higher Initial Investment

Vacuum furnaces are complex machines that represent a significantly higher capital cost compared to conventional atmosphere furnaces.

Potentially Longer Cycle Times

The need to pump the chamber down to a vacuum, followed by controlled heating and cooling ramps, can result in longer overall cycle times compared to some continuous atmosphere furnace operations.

The Myth of a "Perfect" Vacuum

The term "vacuum" refers to a low-pressure environment, not a perfect void. The quality of the vacuum is critical, and for processes like carburizing or gas quenching, specific gases are intentionally introduced back into the chamber.

Making the Right Choice for Your Application

Selecting the right thermal process depends entirely on your material, part geometry, and final performance requirements.

- If your primary focus is superior surface quality and minimal distortion: Vacuum heat treatment is the definitive choice, especially for finished or near-net-shape parts where post-processing is undesirable.

- If your primary focus is processing highly reactive metals (like titanium) or sensitive alloys: The inert environment of a vacuum furnace provides essential protection against contamination that would ruin the material in a standard atmosphere.

- If your primary focus is high-volume, low-cost production where surface oxidation is acceptable: Traditional atmosphere furnaces may offer a more economical solution for simple parts and materials.

Understanding these core principles empowers you to select the heat treatment method that delivers the precise metallurgical outcome your project demands.

Summary Table:

| Process Type | Key Applications | Benefits in Vacuum |

|---|---|---|

| Quenching | Gas, Oil, Water Quenching | Minimizes distortion, clean cooling |

| Annealing & Tempering | Softening, stress relief | Precise temperature control, no surface contamination |

| Case Hardening | Carburizing, Nitriding | Controlled gas infusion, wear-resistant surfaces |

| Specialized Processes | Brazing, Sintering, Degassing | Flux-free joining, gas removal for embrittlement prevention |

Ready to elevate your material processing with contamination-free heat treatment? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability