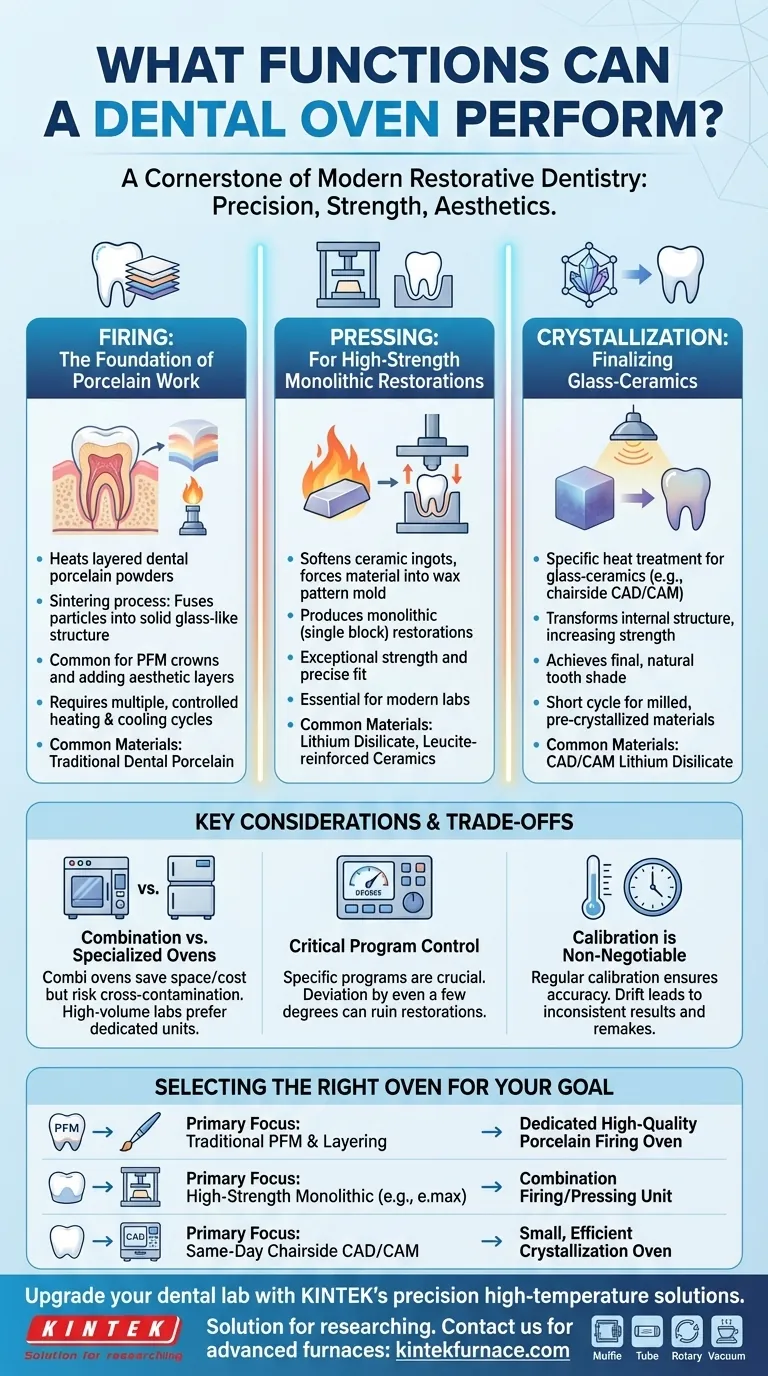

In a modern dental lab or clinic, the dental oven is a cornerstone of restorative dentistry. It is a highly specialized appliance responsible for transforming various ceramic materials into their final, durable state. Depending on the model, a dental oven can perform three primary functions: firing traditional porcelains, pressing high-strength ceramics, and crystallizing modern CAD/CAM materials.

A dental oven is more than just a heating device; it is an instrument of precision. Its core purpose is to execute highly specific temperature and time cycles that are critical for achieving the strength, fit, and aesthetics required for successful dental restorations.

The Core Functions Explained

Each function of a dental oven corresponds to a different type of material and restorative technique. Understanding the distinction is key to producing predictable, high-quality results.

Firing: The Foundation of Porcelain Work

Firing is the process of heating layered dental porcelain powders until they sinter, or fuse together, into a solid, glass-like structure. This is the classic method used for creating porcelain-fused-to-metal (PFM) crowns and for adding aesthetic layers to other substructures.

The process involves multiple, carefully controlled heating and cooling cycles. An inaccurate firing cycle can result in a restoration that is porous, weak, or has poor color and translucency.

Pressing: For High-Strength Monolithic Restorations

Pressing involves heating a ceramic ingot until it softens and then using pneumatic pressure to force the material into a mold created from a wax pattern. This technique is used for materials like lithium disilicate and leucite-reinforced ceramics.

This method produces monolithic restorations—meaning they are fabricated from a single block of material. The result is a restoration with exceptional strength and an extremely precise fit, making press ovens essential for many modern labs.

Crystallization: Finalizing Glass-Ceramics

Crystallization is a specific heat treatment required for certain glass-ceramic materials, most notably the lithium disilicate used in chairside CAD/CAM systems.

These materials are milled in a pre-crystallized, weaker state (often appearing bluish-purple). A short cycle in a crystallization oven transforms the material's internal structure, dramatically increasing its strength and bringing it to its final, natural-looking tooth shade.

Understanding the Trade-offs

While these ovens are indispensable, selecting and using one requires an awareness of their operational distinctions and limitations.

Combination Ovens vs. Specialized Units

Many manufacturers offer "combi" ovens that can perform both firing and pressing. These are excellent for saving space and reducing initial investment, making them popular in many labs.

However, a potential trade-off is the risk of cross-contamination. Remnants of investment material from the pressing process can inadvertently contaminate the firing chamber, potentially affecting the aesthetics of layered porcelain. High-volume labs often prefer dedicated units for each task to maximize efficiency and purity.

The Critical Role of Program Control

Modern dental ceramics are highly engineered materials, and each one has a specific firing or pressing program recommended by the manufacturer. Using the wrong program—even one that is off by a few degrees—can ruin a restoration.

The quality of an oven is often defined by its ability to precisely store, customize, and execute these complex programs without deviation.

Calibration is Non-Negotiable

The temperature inside the oven's muffle must be exact. Over time, thermocouples can drift, leading to inaccurate readings.

Regular calibration is essential to ensure the temperature displayed is the true temperature being applied to the restoration. Failure to calibrate is a common source of inconsistent results, remakes, and wasted materials.

Selecting the Right Oven for Your Goal

Your choice of oven should be driven directly by the types of restorations you plan to produce.

- If your primary focus is traditional PFM crowns and porcelain layering: A dedicated, high-quality porcelain firing oven is your essential workhorse.

- If your primary focus is high-strength monolithic restorations (e.g., e.max): A press oven is mandatory, and a combination firing/pressing unit is a highly practical and common choice.

- If your primary focus is same-day chairside dentistry with CAD/CAM: A small, fast, and efficient crystallization oven is a non-negotiable component of your workflow.

Understanding these core functions empowers you to select the precise tool needed to consistently produce exceptional dental restorations.

Summary Table:

| Function | Description | Common Materials |

|---|---|---|

| Firing | Heats porcelain powders to fuse into solid structures, ideal for layered restorations like PFM crowns. | Traditional dental porcelain |

| Pressing | Softens ceramic ingots and uses pressure to mold into monolithic restorations for high strength and fit. | Lithium disilicate, leucite-reinforced ceramics |

| Crystallization | Transforms pre-crystallized glass-ceramics to increase strength and achieve final tooth shade. | CAD/CAM lithium disilicate |

Upgrade your dental lab with precision high-temperature solutions from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced furnaces tailored for dental applications, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met, enhancing efficiency and quality in restorative dentistry. Contact us today to discuss how our solutions can transform your workflow!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations