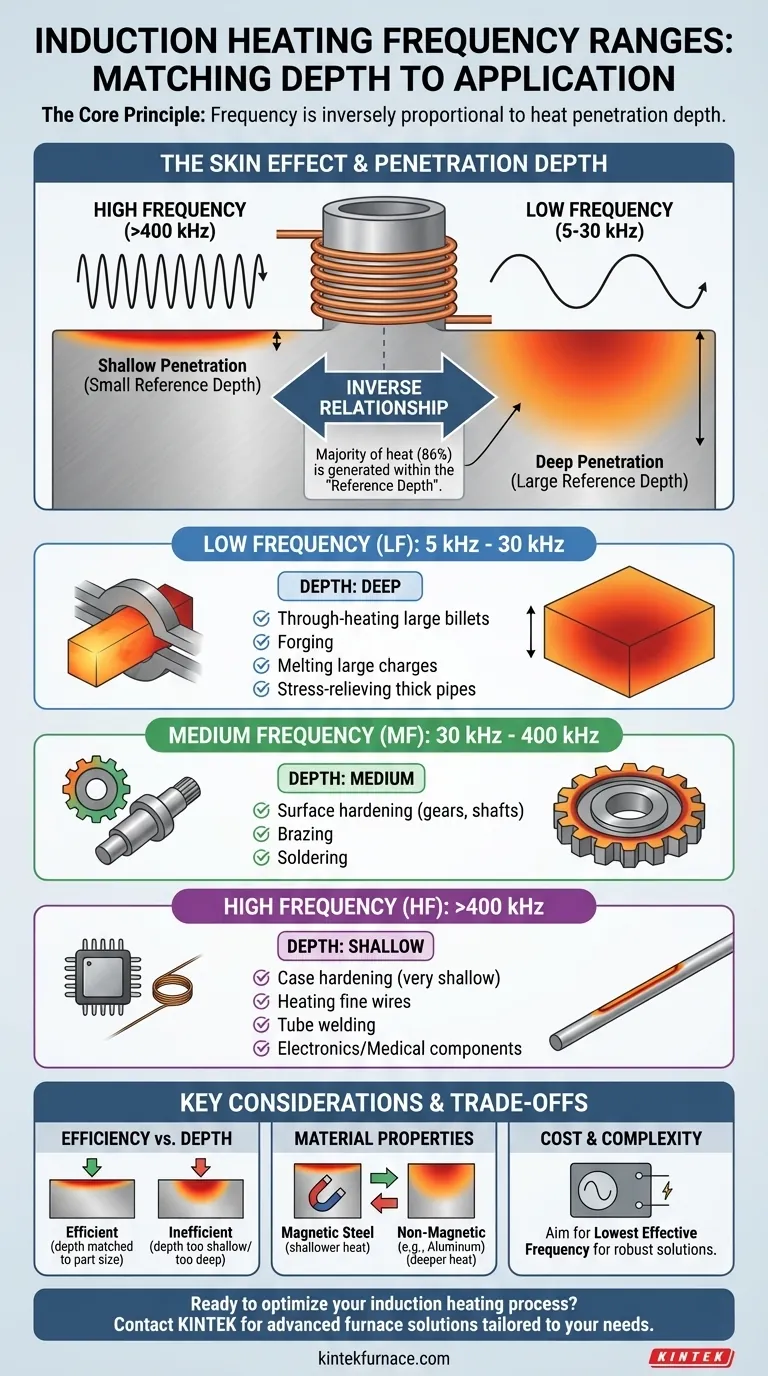

Induction heating frequencies are selected based on a fundamental principle: the desired depth of heat penetration into the material. The frequency is inversely proportional to this depth. Low frequencies (5-30 kHz) are used for deep heating of thick parts, medium frequencies (100-400 kHz) are for smaller parts or surface hardening, and high frequencies (above 400 kHz) are for precision heating of very small parts or extremely shallow surfaces.

The core principle is an inverse relationship: the higher the frequency, the shallower the heat penetration. Choosing the right frequency is not about the application name, but about matching the heating depth to the geometry and metallurgical requirements of the workpiece.

The Core Principle: Frequency and Penetration Depth

To select the right frequency, you must first understand the physics of how induction generates heat. The process is governed by a phenomenon known as the "skin effect."

Introducing the "Skin Effect"

When an alternating current (AC) flows through a conductor, it tends to be most dense at the surface and its density decreases exponentially toward the center. Induction heating works by inducing these "eddy currents" in the workpiece without contact.

Because of the skin effect, the majority of the heating occurs in a finite layer near the surface of the part.

Defining "Reference Depth"

Engineers use a specific metric called reference depth (or penetration depth). This is the depth from the surface where the induced current density has fallen to approximately 37% of its value at the surface.

Crucially, about 86% of the total heat generated by the induced currents is produced within this reference depth. It is the primary variable you control with frequency.

The Inverse Relationship

The relationship is simple and direct:

- Low Frequency = Large Reference Depth = Deep Heat Penetration

- High Frequency = Small Reference Depth = Shallow Heat Penetration

Controlling the frequency allows you to precisely control where the heat is generated within the part, which is the key to successful induction heating.

A Practical Guide to Frequency Bands

Different industries have standardized around specific frequency ranges that are optimized for common tasks.

Low Frequency (LF): 5 kHz to 30 kHz

This range is used for applications requiring deep, uniform heating. The low frequency allows the eddy currents to penetrate far into the material.

Common uses include the through-heating of large billets for forging, melting large metal charges, and stress-relieving thick-walled pipes.

Medium Frequency (MF): 30 kHz to 400 kHz

This is arguably the most versatile and common range in induction heating. It provides a good balance between penetration depth and heating speed.

Its primary application is surface hardening of parts like gears, shafts, and bearings, where you need a hard, wear-resistant surface while maintaining a ductile core. It is also widely used for brazing and soldering.

High Frequency (HF): Above 400 kHz

High frequencies are used when the heating must be confined to an extremely thin surface layer or when the part itself is very small.

This is ideal for case hardening with very shallow depths, heating fine wires, tube welding, or heating microscopic components in the electronics and medical industries.

Understanding the Trade-offs

Choosing a frequency is not always straightforward. You must consider the interplay between the part, the process, and the equipment.

Efficiency vs. Depth

For efficient heating, the reference depth should be significantly smaller than the thickness or radius of the part. If the frequency is too low for the part size, the magnetic field can pass straight through, resulting in poor energy transfer.

Conversely, if the frequency is excessively high for the required case depth, you are only heating a razor-thin layer. This can be inefficient and require longer heat "soak" times for the heat to conduct inward to the desired depth.

Material Properties Matter

The reference depth is also determined by the material's electrical resistivity and magnetic permeability.

For example, the same frequency will produce a much shallower heating depth in magnetic steel (below its Curie temperature) than in non-magnetic stainless steel or aluminum. This must be factored into your calculations.

Cost and Complexity of Equipment

As a general rule, power supplies for different frequency ranges involve different technologies. The goal is to always use the lowest frequency that effectively achieves the desired heating profile, as this often corresponds to the most robust and cost-effective equipment solution.

Making the Right Choice for Your Goal

To select the correct frequency, you must first define your primary heating objective.

- If your primary focus is through-heating a large, thick part: Use low frequencies (5-30 kHz) to ensure the heat penetrates deeply and evenly.

- If your primary focus is surface hardening a component: Select a medium frequency (30-400 kHz) that creates a heating depth appropriate for the required case depth.

- If your primary focus is heating a very small part or an extremely thin surface layer: Opt for high frequencies (>400 kHz) to concentrate the energy precisely where it's needed.

Ultimately, the correct frequency is the one that most efficiently places the heat exactly where your process requires it.

Summary Table:

| Frequency Range | Penetration Depth | Common Applications |

|---|---|---|

| 5 kHz - 30 kHz | Deep | Through-heating large billets, forging, stress-relieving thick pipes |

| 30 kHz - 400 kHz | Medium | Surface hardening (gears, shafts), brazing, soldering |

| Above 400 kHz | Shallow | Case hardening, heating fine wires, tube welding, electronics |

Ready to optimize your induction heating process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights