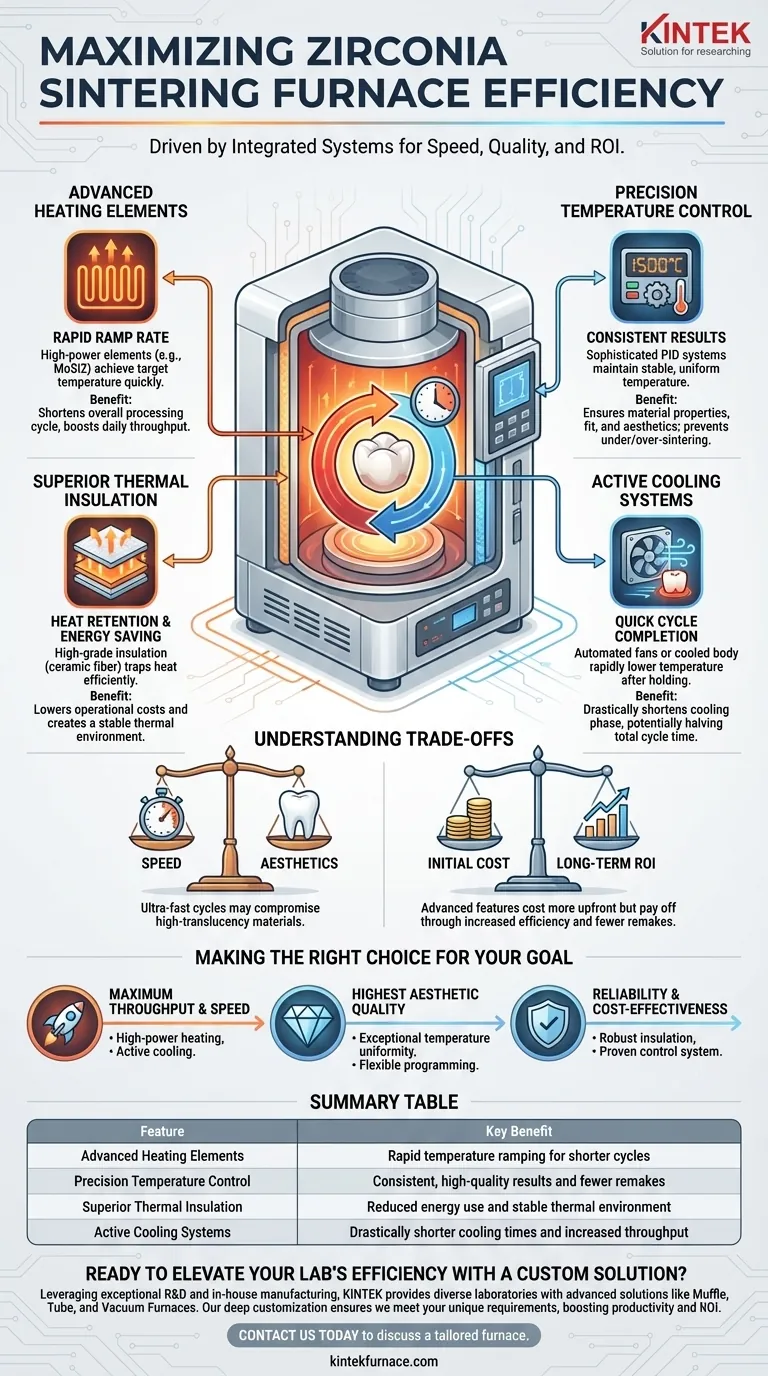

In short, the efficiency of a zirconia sintering furnace is primarily driven by three integrated systems: advanced heating elements for rapid temperature ramping, superior thermal insulation to retain heat and reduce energy use, and precise temperature control to ensure consistent, high-quality results. Modern designs also incorporate active cooling systems to drastically shorten the total cycle time, directly boosting lab productivity.

True furnace efficiency is not just about speed; it is the predictable and repeatable achievement of ideal material properties. This is accomplished through a symbiotic relationship between rapid heating, stable temperature maintenance, and swift, controlled cooling.

The Core Pillars of Sintering Efficiency

A furnace's performance is determined by how well its core components work together. Understanding these pillars is key to evaluating a furnace for speed, quality, and return on investment.

Advanced Heating Elements

The heart of the furnace is its heating system. Modern elements, often made of Molybdenum Disilicide (MoSi2), are designed for extremely rapid heating rates, known as the ramp rate.

A faster ramp rate directly reduces the time it takes to reach the target sintering temperature. This shortens the overall processing cycle, allowing a dental lab to complete more cases per day.

Precision Temperature Control

Efficiency is wasted without accuracy. A sophisticated temperature control system is non-negotiable for producing restorations with consistent strength, fit, and aesthetics.

These systems use high-quality thermocouples and PID (Proportional-Integral-Derivative) controllers to maintain a stable and uniform temperature throughout the firing chamber. This precision prevents under-sintering, which compromises strength, or over-sintering, which can affect shade and translucency.

Superior Thermal Insulation

What happens to the heat generated is just as important as how it's created. High-grade insulation, such as multi-layer ceramic fiber or double-layer air insulation, traps heat within the chamber.

This has two major benefits. First, it reduces energy consumption, lowering operational costs. Second, it creates a highly stable thermal environment, which contributes to the consistency and reproducibility of results from one cycle to the next.

Active Cooling Systems

Historically, the cooling phase was a passive, time-consuming part of the process. Modern high-efficiency furnaces incorporate active cooling systems, such as automated cooling fans or a strongly cooled furnace body.

These systems rapidly and safely bring the temperature down after the sintering hold time is complete. By dramatically shortening the cooling phase, active cooling can cut the total cycle time nearly in half, representing the single largest leap in furnace productivity.

Understanding the Trade-offs

Selecting a furnace involves balancing competing priorities. The most "efficient" choice depends entirely on your specific goals.

Speed vs. Aesthetic Demands

Ultra-fast sintering cycles are excellent for productivity but may not be suitable for all zirconia materials, especially high-translucency anterior zirconia. These materials often require slower, more controlled heating and cooling to achieve optimal aesthetics.

Pushing a material beyond its recommended sintering protocol can compromise its final shade and translucency, leading to a remake that negates any time saved.

Initial Cost vs. Long-Term ROI

Furnaces with the most advanced features—especially active cooling and highly precise temperature controls—carry a higher initial purchase price.

However, this cost is often justified by a clear return on investment. The increased throughput, lower energy bills, and dramatic reduction in costly remakes mean the furnace pays for itself over time through superior operational efficiency.

Making the Right Choice for Your Goal

Use your primary objective to guide your evaluation of a furnace's features.

- If your primary focus is maximum throughput and speed: Prioritize furnaces with high-power heating elements for fast ramp rates and, most importantly, an active cooling system.

- If your primary focus is the highest aesthetic quality: Emphasize furnaces renowned for their exceptional temperature uniformity and the flexibility to program custom, multi-stage cycles.

- If your primary focus is reliability and cost-effectiveness: Look for robust thermal insulation to lower energy costs and a proven temperature control system to minimize remakes.

Understanding how these core features serve your lab's unique goals empowers you to make an investment that delivers both clinical excellence and business success.

Summary Table:

| Feature | Key Benefit |

|---|---|

| Advanced Heating Elements | Rapid temperature ramping for shorter cycles |

| Precision Temperature Control | Consistent, high-quality results and fewer remakes |

| Superior Thermal Insulation | Reduced energy use and stable thermal environment |

| Active Cooling Systems | Drastically shorter cooling times and increased throughput |

Ready to elevate your lab's efficiency with a custom high-temperature furnace solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, boosting productivity and ROI. Contact us today to discuss how we can tailor a furnace for your needs!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures