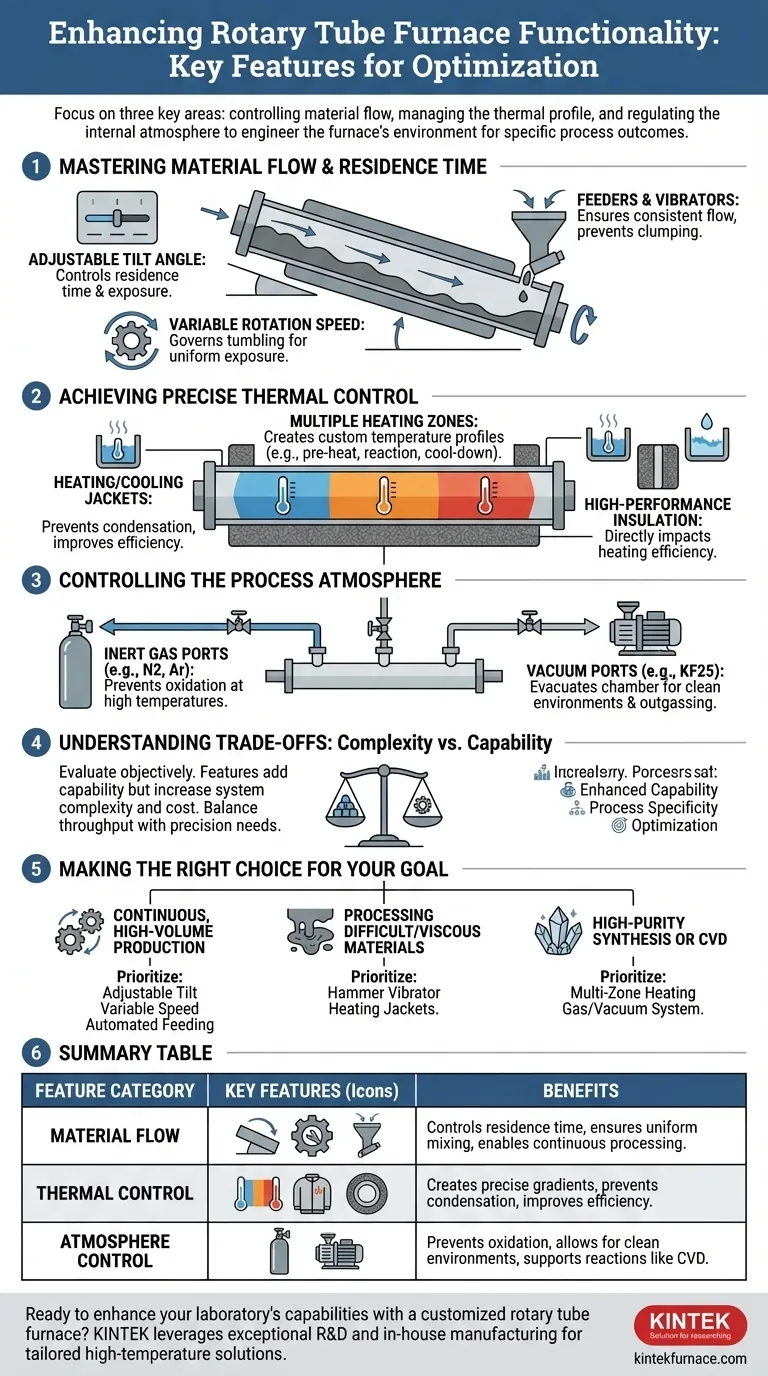

To enhance functionality, a rotary tube furnace can be equipped with a range of features focused on three key areas: controlling material flow, managing the thermal profile, and regulating the internal atmosphere. These include adjustable tilt angles and variable rotation speeds for material handling, multiple independent heating zones for precise temperature gradients, and specialized gas ports for creating controlled environments.

The selection of features is not about adding capabilities for their own sake. It is about deliberately engineering the furnace's dynamic environment to match the specific physical and chemical requirements of your material and your desired process outcome.

Mastering Material Flow and Residence Time

The core advantage of a rotary furnace is its ability to process materials dynamically. Features that control this movement are fundamental to optimizing your results.

Tilt Angle and Inclination

A furnace with an adjustable tilt angle is essential for continuous or semi-continuous processing.

By changing the incline of the rotating tube, you can precisely control the rate at which material travels through the furnace. This directly dictates the residence time—how long the material is exposed to the heat.

Variable Rotation Speed

DC variable speed control governs how the material tumbles inside the tube.

A slower speed provides gentle mixing, while a faster speed creates more aggressive tumbling. This allows you to ensure every particle is uniformly exposed to the heat, preventing hot spots and achieving a homogenous final product.

Feeders and Vibrators

For materials that are sticky, viscous, or prone to clumping, a hammer vibrator can be installed. This device applies mechanical vibration to the tube, dislodging material and ensuring consistent flow.

Additionally, automated feeders can be integrated to introduce raw material into the furnace at a controlled rate, enabling true continuous batch processing.

Achieving Precise Thermal Control

Uniform heating is a baseline expectation. Advanced thermal features allow you to create sophisticated temperature profiles along the length of the furnace tube.

Multiple Heating Zones

Perhaps the most powerful thermal feature is the use of multiple, independently controlled heating zones.

This allows you to create a specific temperature profile. For example, you can establish a pre-heating zone, a primary reaction zone at a higher temperature, and a cool-down zone, all within a single pass.

Enhanced Heating and Cooling

For processes that produce condensable byproducts, such as tar from organic materials, heating jackets can be fitted around the tube's ends. These prevent condensation and blockages.

Conversely, some designs incorporate air cooling systems to improve thermal efficiency and help balance the temperature field across the zones.

High-Performance Insulation

Modern furnaces use high-quality ceramic fiber insulation. While a standard component, its quality directly impacts heating efficiency and energy consumption, making it a critical performance feature.

Controlling the Process Atmosphere

For many applications, from calcination to chemical vapor deposition (CVD), controlling the atmosphere inside the furnace is non-negotiable.

Inert Gas and Vacuum Ports

An inert gas package, including dedicated in/out ports (e.g., 1/4 inch gas ports), allows you to flood the tube with gases like argon or nitrogen. This prevents unwanted oxidation of the material at high temperatures.

For applications requiring a clean environment or outgassing, a KF25 outgassing port enables connection to a vacuum system, allowing you to efficiently evacuate the chamber.

Understanding the Trade-offs: Complexity vs. Capability

While these features add significant capability, they also introduce complexity and cost. It is crucial to evaluate this trade-off objectively.

System Integration and Maintenance

Each added feature, from a vibrator to a multi-zone controller, increases the system's complexity. This can lead to higher initial costs, more sophisticated control requirements, and a greater need for routine maintenance.

Process-Specific Needs

A simple furnace with one heating zone is robust and perfectly adequate for basic calcination. However, it is entirely unsuitable for a multi-stage reaction requiring a precise temperature gradient and inert atmosphere. The features are only valuable if the process demands them.

Throughput vs. Precision

Features that boost throughput, like automated feeders and continuous tilting, may require sacrificing some degree of the ultra-fine precision possible in a smaller, static batch furnace. The goal is to find the right balance for your specific application.

Making the Right Choice for Your Goal

Select features based on the primary objective of your process.

- If your primary focus is continuous, high-volume production: Prioritize an adjustable tilt angle, variable speed control, and an automated feeding system.

- If your primary focus is processing difficult or viscous materials: A hammer vibrator is essential, and heating jackets may be needed to prevent blockages.

- If your primary focus is high-purity synthesis or CVD: Multi-zone heating and a comprehensive gas handling system with vacuum-rated ports are non-negotiable.

Ultimately, the right configuration transforms the furnace from a simple heater into a precision instrument tailored to your exact process needs.

Summary Table:

| Feature Category | Key Features | Benefits |

|---|---|---|

| Material Flow | Adjustable tilt angle, Variable rotation speed, Hammer vibrator, Automated feeders | Controls residence time, ensures uniform mixing, prevents clumping, enables continuous processing |

| Thermal Control | Multiple heating zones, Heating jackets, Air cooling systems, High-quality insulation | Creates precise temperature gradients, prevents condensation, improves efficiency, reduces energy use |

| Atmosphere Control | Inert gas ports, Vacuum ports (e.g., KF25) | Prevents oxidation, allows for clean environments, supports reactions like CVD |

Ready to enhance your laboratory's capabilities with a customized rotary tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're focused on continuous production, handling difficult materials, or high-purity synthesis, we can design a furnace that precisely matches your experimental requirements. Contact us today to discuss how we can optimize your processes and drive your research forward!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules