At its core, selecting the right crucible material for a vacuum casting furnace is a balancing act between three critical factors: chemical inertness, thermal stability, and mechanical durability. The goal is to choose a material that will not melt, break, or contaminate your alloy during the high-temperature, high-vacuum casting process, ensuring the integrity and purity of your final product.

The most common mistake is viewing the crucible as a simple container. In reality, it is an active component in a complex metallurgical system. The right choice prevents catastrophic melt contamination and process failure, while the wrong choice guarantees it.

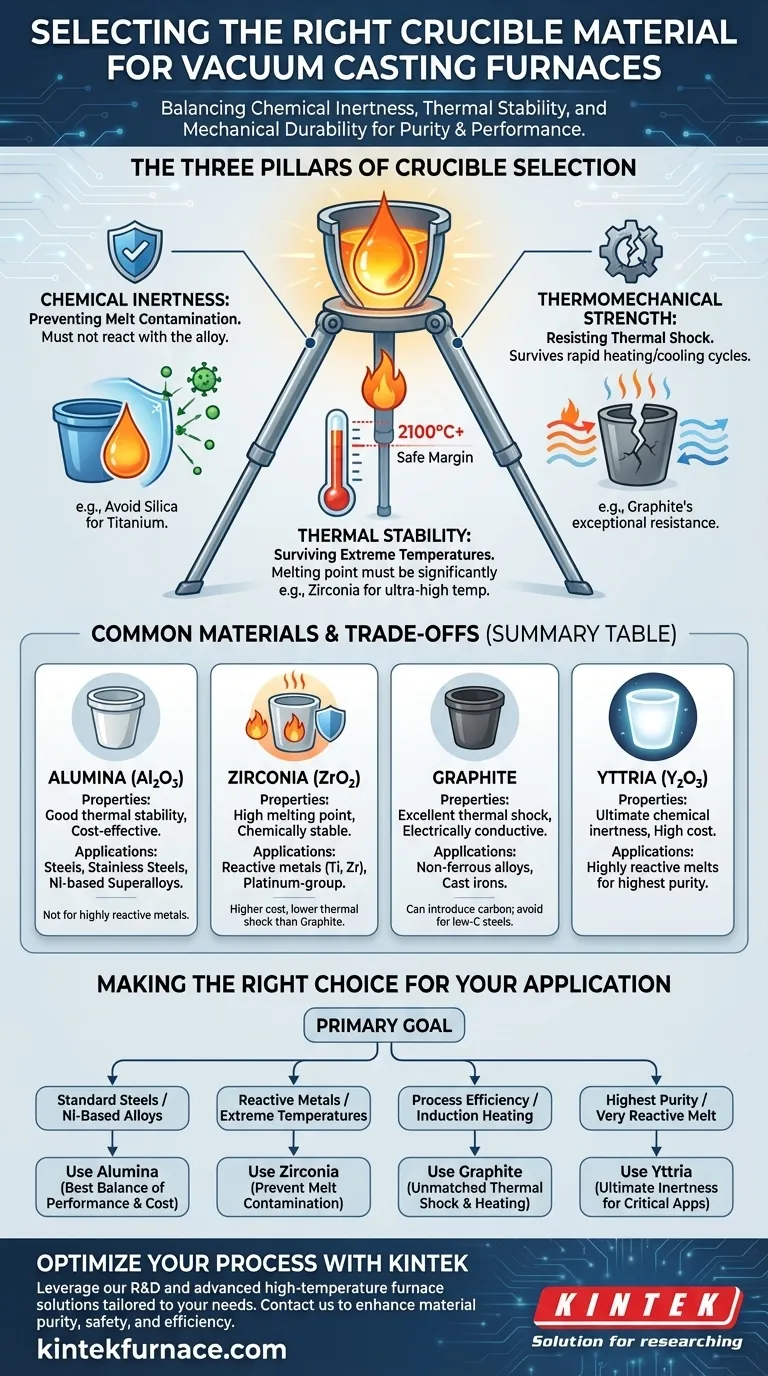

The Three Pillars of Crucible Selection

Your decision-making process should be founded on a clear understanding of how your chosen material will behave under the extreme conditions of your furnace. These three pillars are non-negotiable.

Chemical Inertness: Preventing Melt Contamination

The primary function of the vacuum environment is to prevent the molten metal from reacting with atmospheric gases. However, a reaction between the liquid metal and the crucible itself can be just as damaging.

The crucible material must be chemically inert with respect to the specific alloy being melted. If it is not, the crucible can dissolve into the melt, introducing impurities that alter the final alloy's chemical and mechanical properties.

For example, using a silica-based crucible to melt titanium would be disastrous, as the highly reactive titanium would strip oxygen from the silica, contaminating the melt and destroying the crucible.

Thermal Stability: Surviving Extreme Temperatures

This factor seems obvious but has important nuances. The crucible's melting point must be significantly higher than the maximum processing temperature of your alloy.

A safe margin is crucial. Operating too close to a crucible's softening point can lead to deformation or, in a worst-case scenario, a complete failure and loss of the molten charge inside the furnace chamber.

Materials like zirconia are selected for ultra-high-temperature applications (above 2100°C) precisely because they maintain their structural integrity far beyond the melting point of most commercial alloys.

Thermomechanical Strength: Resisting Thermal Shock

Vacuum casting cycles often involve rapid heating and cooling. These temperature gradients create internal stresses within the crucible material.

A material with poor thermal shock resistance will crack and fail prematurely, sometimes after only a few cycles. This is not only costly in terms of replacement crucibles but also poses a significant safety risk.

Graphite, for instance, is prized for its exceptional thermal shock resistance, allowing it to survive thousands of rapid heating and cooling cycles without failing.

Understanding the Trade-offs: Common Crucible Materials

There is no single "best" material; each involves a trade-off between performance, application, and cost.

Alumina (Al₂O₃)

Alumina is a cost-effective workhorse for melting many common alloys. It offers good thermal stability and is relatively inert to many materials.

It is the standard choice for melting steels, stainless steels, and many nickel-based superalloys. However, it is not suitable for highly reactive metals like titanium or zirconium.

Zirconia (ZrO₂)

When melting reactive metals or alloys at extreme temperatures, zirconia is the industry standard. Its chemical stability and very high melting point make it one of the few viable options.

It is essential for processing titanium, zirconium, uranium, and platinum-group metals. Its primary downside is a higher cost and typically lower thermal shock resistance compared to graphite. It is often stabilized with yttria (Yttria-Stabilized Zirconia, or YSZ) to improve its thermomechanical properties.

Graphite

Graphite stands apart due to its excellent thermal shock resistance and electrical conductivity. In an induction furnace, a graphite crucible can serve as both the container and the heating element (susceptor).

It is ideal for many non-ferrous alloys and cast irons. Its main limitation is that it can introduce carbon into the melt, making it unsuitable for producing low-carbon or extra-low-carbon steels. It will also oxidize and degrade rapidly if the vacuum integrity is poor.

Yttria (Y₂O₃)

For the most demanding applications involving highly reactive melts where even zirconia is insufficient, yttria offers the ultimate level of chemical inertness. It is exceptionally stable but is also significantly more expensive and is reserved for critical, high-value applications.

Making the Right Choice for Your Application

Use this as a starting point to guide your material selection based on your primary metallurgical goal.

- If your primary focus is casting standard steels or nickel-based alloys: Alumina offers the best balance of performance and cost efficiency.

- If your primary focus is casting reactive metals (e.g., titanium) or working at extreme temperatures: Zirconia (often yttria-stabilized) is the necessary choice to prevent melt contamination.

- If your primary focus is process efficiency in an induction furnace and slight carbon pickup is acceptable: Graphite provides unmatched thermal shock resistance and heating performance.

- If your primary focus is achieving the absolute highest purity with a very reactive melt: You must invest in a specialized material like Yttria.

Ultimately, selecting a crucible material is a critical process decision that directly impacts product quality, operational safety, and economic efficiency.

Summary Table:

| Crucible Material | Key Properties | Common Applications |

|---|---|---|

| Alumina (Al₂O₃) | Good thermal stability, cost-effective | Steels, stainless steels, nickel-based superalloys |

| Zirconia (ZrO₂) | High melting point, chemically stable | Reactive metals like titanium, zirconium, platinum-group metals |

| Graphite | Excellent thermal shock resistance, electrically conductive | Non-ferrous alloys, cast irons (avoid for low-carbon steels) |

| Yttria (Y₂O₃) | Ultimate chemical inertness, high cost | Highly reactive melts for highest purity applications |

Ready to optimize your vacuum casting process with the right crucible? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can enhance your material purity, safety, and efficiency!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications