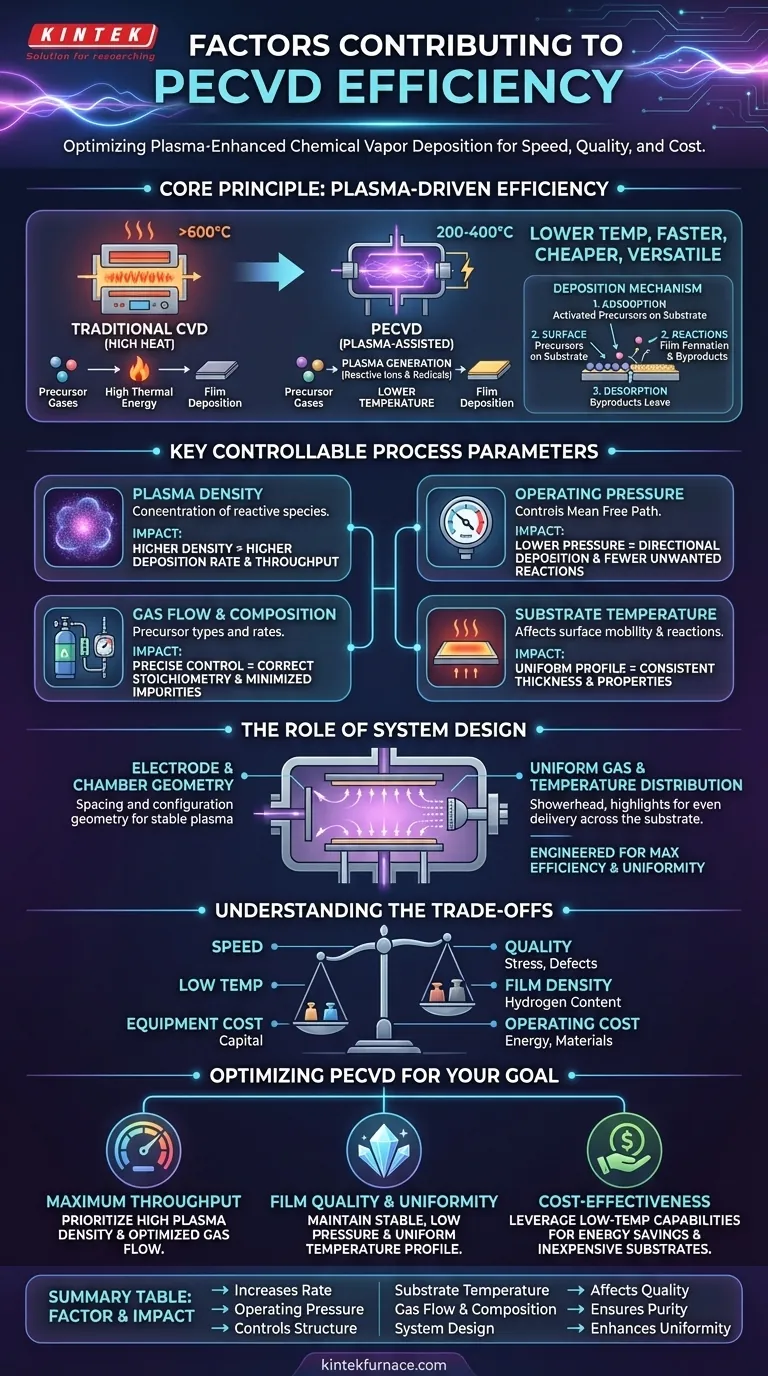

The efficiency of Plasma-Enhanced Chemical Vapor Deposition (PECVD) is determined by a combination of controllable process parameters and the fundamental design of the system itself. Key factors include plasma density, operating pressure, substrate temperature, and the uniformity of gas distribution. These elements work together to dictate the speed, quality, and cost-effectiveness of the film deposition process.

PECVD's core efficiency comes from its strategic use of plasma to generate reactive chemical species at low temperatures. This bypasses the need for the high thermal energy required by conventional CVD, resulting in faster, cheaper, and more versatile thin-film fabrication.

The Core Principle: Plasma-Driven Efficiency

The fundamental advantage of PECVD lies in how it generates the energy needed for chemical reactions.

How Plasma Replaces High Heat

Traditional Chemical Vapor Deposition (CVD) relies on high temperatures (often >600°C) to break down precursor gases and deposit a film.

PECVD uses an electric field to create plasma, an energized state of gas. This plasma contains highly reactive ions and radicals that can initiate deposition reactions at much lower temperatures (typically 200-400°C).

This reduction in thermal energy is the primary source of PECVD's efficiency, lowering power consumption and allowing for deposition on temperature-sensitive materials like plastics.

The Deposition Mechanism

The process occurs in a few key steps. First, activated precursor molecules from the plasma adsorb onto the substrate surface.

Next, surface reactions form the desired film and create chemical byproducts. Finally, these byproducts desorb from the surface, completing the deposition cycle. The speed and quality of this cycle are governed by the process parameters.

Key Process Parameters You Can Control

Optimizing a PECVD process involves carefully tuning several interdependent variables to achieve the desired outcome.

Plasma Density: The Engine of the Reaction

Plasma density refers to the concentration of reactive species within the chamber. Increasing the density directly increases the deposition rate, leading to higher throughput.

Higher density also enables operation at lower pressures, giving you more precise control over the process.

Operating Pressure: Controlling the Environment

Pressure influences the mean free path—the average distance a particle travels before colliding with another.

Lowering the pressure increases this path, leading to more directional deposition and fewer unwanted gas-phase reactions. This gives engineers greater control over the film's structure and properties.

Gas Flow and Composition: The Building Blocks

The type and flow rate of precursor gases, managed by mass-flow-controlled gas lines, are the raw materials for the film.

Precise control over the gas mixture is essential for achieving the correct film stoichiometry and minimizing impurities.

Substrate Temperature: A Critical Balancing Act

While PECVD operates at low temperatures, this parameter is still critical. Temperature affects surface mobility, chemical reaction rates, and the incorporation of elements like hydrogen into the film.

Maintaining a uniform temperature profile across the entire substrate is crucial for depositing a film with consistent thickness and properties.

The Role of System Design

The physical hardware of the PECVD system is engineered specifically to maximize efficiency and uniformity.

Electrode and Chamber Geometry

The design of the process chamber, including the spacing and configuration of the upper and lower electrodes, is engineered to create a stable and uniform plasma field. This directly impacts the consistency of the deposition across the wafer.

Uniform Gas and Temperature Distribution

Advanced PECVD systems feature proprietary reactor designs and gas distribution "showerheads." These components ensure that precursor gases and heat are delivered evenly across the substrate surface.

This uniformity is a hallmark of an efficient process, as it results in higher yields and layers with reduced cracking or defects.

Understanding the Trade-offs

Efficiency in PECVD is not a single goal but a balance of competing factors. Understanding these trade-offs is key to process optimization.

Speed vs. Quality

Pushing for the highest possible deposition rate by increasing plasma density or gas flow can sometimes compromise film quality. This may introduce stress, increase defect density, or alter the film's chemical structure.

Low Temperature vs. Film Density

A major benefit of PECVD is its low processing temperature. However, films deposited at lower temperatures can sometimes be less dense or have higher intrinsic hydrogen content compared to films from high-temperature processes, which may not be suitable for all applications.

Equipment Cost vs. Operating Cost

PECVD systems are complex and represent a significant capital investment. This initial cost is justified by major long-term efficiencies, including higher throughput, reduced energy consumption, and the ability to process a wider range of materials compared to traditional methods.

Optimizing PECVD for Your Goal

The "best" parameters depend entirely on your primary objective. Use these guidelines to steer your process development.

- If your primary focus is maximum throughput: Prioritize high plasma density and optimized gas flow rates to achieve the fastest possible deposition.

- If your primary focus is film quality and uniformity: Concentrate on maintaining stable, low pressure and a highly uniform temperature profile across the substrate.

- If your primary focus is cost-effectiveness: Leverage the low-temperature capabilities to minimize energy consumption and enable deposition on inexpensive, temperature-sensitive substrates.

Mastering the interplay between these factors is the key to unlocking the full potential of PECVD for precise, repeatable, and highly efficient thin-film engineering.

Summary Table:

| Factor | Impact on Efficiency |

|---|---|

| Plasma Density | Increases deposition rate and throughput |

| Operating Pressure | Controls film structure and reduces defects |

| Substrate Temperature | Affects film quality and uniformity |

| Gas Flow & Composition | Ensures correct stoichiometry and purity |

| System Design | Enhances plasma and temperature uniformity |

Unlock the full potential of your PECVD processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions like CVD/PECVD Systems tailored for diverse laboratories. Our strong deep customization capability ensures precise alignment with your unique experimental needs, boosting efficiency, throughput, and film quality. Ready to optimize your thin-film deposition? Contact us today to discuss how our solutions can benefit your research or production!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures