In short, channel induction furnaces offer significant environmental benefits by fundamentally changing how metal is heated. They eliminate the direct emissions, waste streams, and energy inefficiencies associated with traditional combustion-based or electrode-based furnaces, resulting in cleaner air, a safer workplace, and greater resource efficiency.

The core environmental advantage of a channel induction furnace is not just a single feature, but its entire operating principle. By using clean, contained electromagnetic energy instead of burning fuel or consuming electrodes, it systematically eliminates the primary sources of pollution found in older melting technologies.

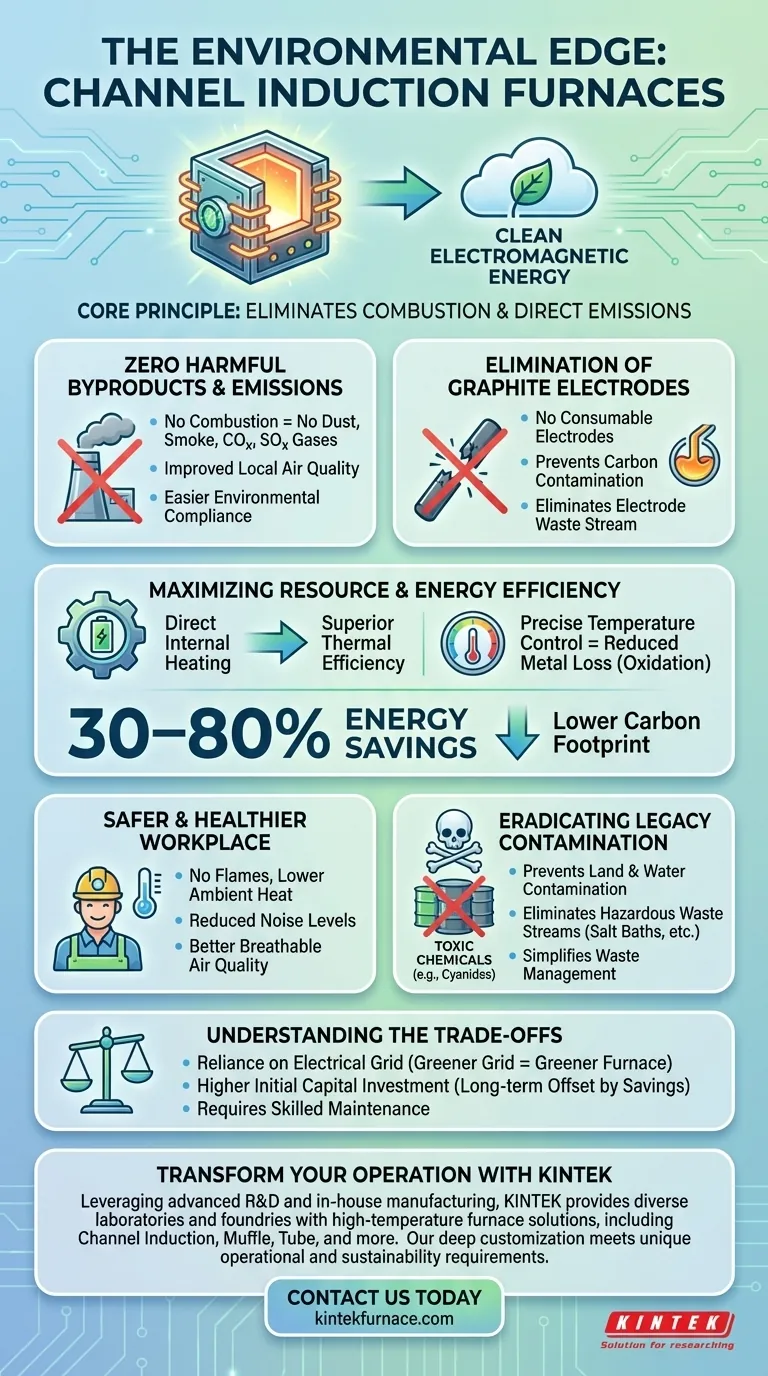

The Foundation: Eliminating Combustion and Direct Emissions

The most immediate environmental impact comes from what a channel induction furnace doesn't produce. Unlike fuel-fired furnaces, the induction process does not rely on combustion, which is the source of most industrial air pollutants.

No Harmful Byproducts

Because there is no burning of fossil fuels, the furnace itself releases no dust, smoke, or harmful gases like carbon oxides and sulfur oxides. This directly improves local air quality and makes it easier to comply with increasingly strict environmental regulations.

Elimination of Graphite Electrodes

Many traditional electric arc furnaces rely on large graphite electrodes, which are consumed during operation. This process can introduce unwanted carbon into the melt and creates a stream of waste material. Induction furnaces do not use electrodes, eliminating both of these issues.

A Cleaner, Safer Workplace

The lack of flames and major exhaust gas emissions dramatically improves the working environment. This results in lower ambient temperatures, reduced noise levels, and better breathable air quality for operators, creating a safer and healthier workplace.

Maximizing Resource and Energy Efficiency

Beyond eliminating direct pollutants, induction technology is inherently more efficient at using energy and materials. This efficiency translates directly into environmental and economic benefits.

Superior Thermal Efficiency

Induction heating works by inducing an electric current directly within the metal itself, generating heat from the inside out. This method is exceptionally efficient, as very little energy is lost to the surrounding environment, unlike furnaces that must heat a large chamber first.

Precise Temperature Control

The technology allows for exact regulation of the melt temperature. This precision minimizes overheating, which reduces metal loss from oxidation and decarburization. Using less raw material to produce the same final product is a significant, though often overlooked, environmental benefit.

Significant Energy Savings

Due to high thermal efficiency and zero heat loss during standby, induction furnaces can offer energy savings of 30–80% compared to traditional methods. This drastic reduction in energy consumption lowers a facility's carbon footprint, especially when powered by a progressively greener electrical grid.

Understanding the Trade-offs

While the benefits are clear, a full technical assessment requires acknowledging the associated considerations. No technology is without its specific context and challenges.

Reliance on the Electrical Grid

The environmental credentials of an induction furnace are directly tied to the source of its electricity. Its "green" benefit is maximized when the power grid is supplied by renewable or low-carbon sources.

Higher Initial Capital Investment

Induction furnace systems often require a larger upfront capital investment compared to some conventional furnaces. However, this cost is frequently offset over the long term by lower energy consumption and reduced material waste.

Maintenance and Technical Skill

These are sophisticated electrical systems that require specialized knowledge for maintenance and repair. Facilities must ensure their technical teams are properly trained to manage the equipment effectively.

Eradicating Legacy Contamination Risks

Perhaps one of the most profound benefits is the elimination of hazardous waste streams associated with older heat-treatment and melting processes.

Preventing Land and Water Contamination

Outdated processes, such as salt bath furnaces, used toxic materials like cyanides that posed a significant risk of land and water contamination. Induction heating completely removes the need for such hazardous chemicals.

Reducing Solid Waste Disposal

Induction technology also eliminates the challenge of disposing of waste from other legacy methods, such as contaminated jigs, fixtures, and waste from pack carburizing. This simplifies waste management and removes long-term environmental liability.

Making the Right Choice for Your Operation

Adopting channel induction technology is a strategic decision that aligns operational efficiency with environmental responsibility. Your primary driver will determine which benefit is most critical.

- If your primary focus is meeting emissions regulations: The complete elimination of direct pollutants like dust and harmful gases is your most compelling advantage.

- If your primary focus is reducing operational costs: The significant, long-term energy savings and reduced material waste offer the most direct and measurable financial return.

- If your primary focus is improving worker safety and ESG metrics: The creation of a cleaner, quieter, and safer workplace combined with the eradication of hazardous materials will be your key selling point.

Ultimately, shifting to induction technology is an investment in a cleaner, more efficient, and more sustainable operational future.

Summary Table:

| Environmental Benefit | Key Feature | Impact |

|---|---|---|

| Zero Direct Emissions | No combustion process | Eliminates dust, smoke, and harmful gases (e.g., COx, SOx) |

| Superior Energy Efficiency | Direct internal heating of metal | Reduces energy consumption by 30–80% compared to traditional methods |

| Reduced Material Waste | Precise temperature control | Minimizes metal loss from oxidation and decarburization |

| Elimination of Hazardous Waste | No toxic chemicals (e.g., cyanides) or consumable electrodes | Prevents land/water contamination and simplifies waste management |

| Safer Workplace | No flames, lower noise, better air quality | Improves operator safety and health |

Ready to transform your metal processing with a cleaner, more efficient solution?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and foundries with advanced high-temperature furnace solutions. Our product line, including Channel Induction, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique operational and sustainability requirements.

Contact us today to discuss how our induction furnace technology can help you eliminate emissions, reduce costs, and create a safer, more sustainable operation.

Get in touch via our Contact Form to speak with an expert!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- What are the applications of hot pressing? Achieve Maximum Material Performance