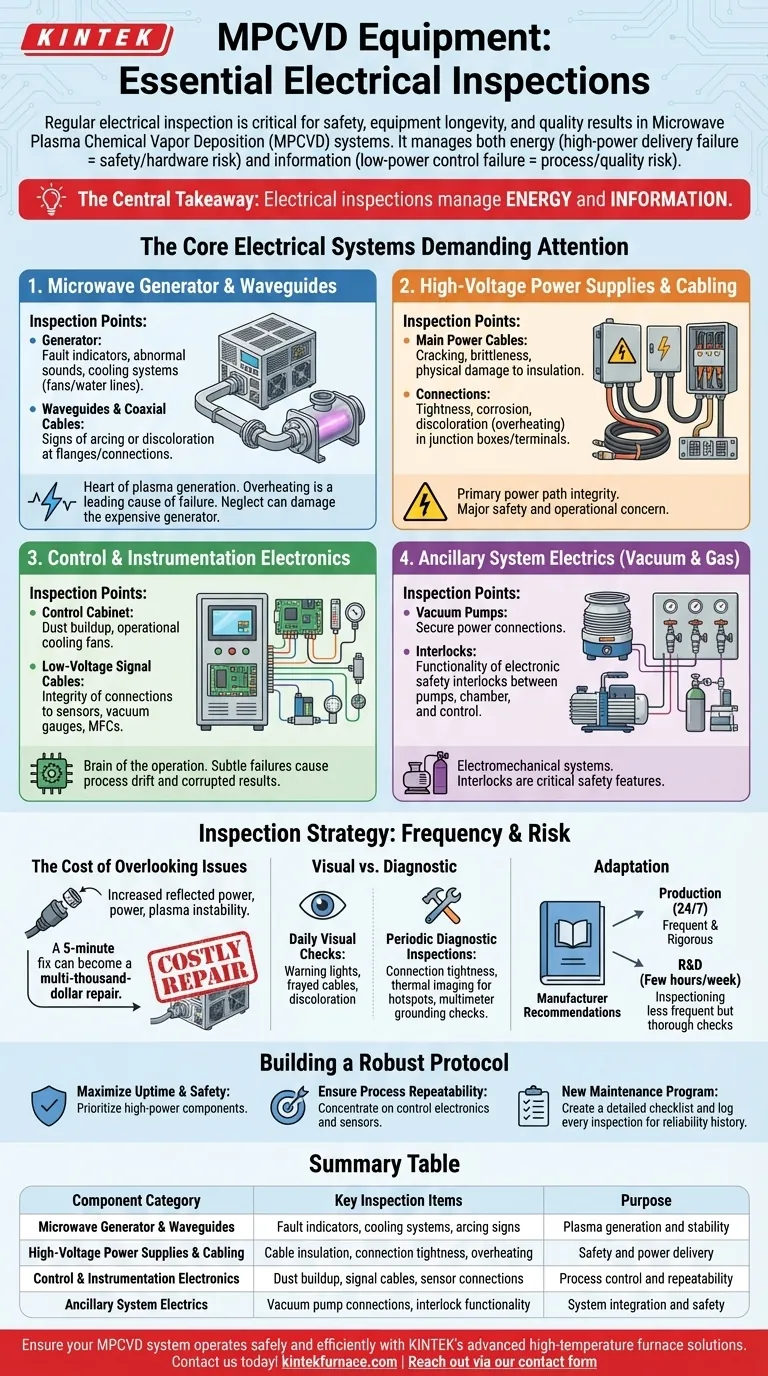

In any Microwave Plasma Chemical Vapor Deposition (MPCVD) system, regular electrical inspection is not just a maintenance task—it's a critical process for ensuring safety, equipment longevity, and the quality of your results. The core components requiring diligent checks are the high-power microwave generator, all associated power cables and connectors, the control system electronics, and the electrical subsystems that power the vacuum pumps and gas delivery.

The central takeaway is this: Electrical inspections in an MPCVD system are fundamentally about managing energy and information. A failure in the high-power delivery system is a safety and hardware risk, while a failure in the low-power control system is a process and quality risk.

The Core Electrical Systems Demanding Attention

An MPCVD system integrates several complex subsystems, all of which rely on a stable and reliable electrical backbone. A failure in one area can cascade, causing costly downtime and failed growth runs. Your inspection protocol should be segmented to address each critical function.

The Microwave Generator and Waveguides

This system is the heart of your plasma generation, converting wall power into the microwave energy that sustains the plasma. It operates at high power and is a primary point of failure if neglected.

Regularly inspect the microwave generator itself for any fault indicators, and listen for abnormal sounds. Check that all cooling systems (air or water) are functioning, as overheating is a leading cause of generator failure. Pay close attention to the waveguide components and any coaxial cables connecting the generator to the plasma chamber, looking for signs of arcing or discoloration at the flanges.

High-Voltage Power Supplies and Cabling

The entire system is fed by high-voltage power. The integrity of this primary power path is a major safety and operational concern.

Your checks should include all main power cables for signs of cracking, brittleness, or physical damage to the insulation. Verify that all connections within junction boxes and at equipment terminals are tight and free of corrosion or overheating, which often appears as discoloration.

Control and Instrumentation Electronics

This is the brain of your operation, responsible for executing recipes and ensuring process stability. Failures here are often subtle and can ruin a batch.

Inspect the control cabinet for dust buildup and ensure cooling fans are operational. Check the integrity of low-voltage signal cables connecting to sensors, vacuum gauges, and mass flow controllers (MFCs). A loose or intermittent connection here can cause process drift that corrupts your results without triggering a major system fault.

Ancillary System Electrics (Vacuum & Gas)

Your vacuum pumps and gas delivery systems are not merely mechanical; they are electromechanical systems that must be inspected as part of the electrical ecosystem.

Confirm that power connections to all vacuum pumps (roughing and turbo pumps) are secure. Ensure that any electronic interlocks between the pumps, chamber, and control system are functioning correctly. These interlocks are critical safety features that prevent dangerous operational states.

Understanding the Trade-offs: Inspection Frequency vs. Risk

A maintenance schedule is not one-size-fits-all. It's a balance between the cost of downtime for inspection and the risk of an unscheduled, catastrophic failure.

The Cost of Overlooking "Minor" Issues

A seemingly minor issue, like a loose connector on a waveguide, is never truly minor. It can increase reflected power, leading to plasma instability, inefficient power delivery, and eventual damage to the expensive microwave generator. What starts as a five-minute fix can become a multi-thousand-dollar repair.

Visual vs. Diagnostic Inspections

Your inspection protocol should have two tiers. Daily visual checks involve looking for obvious signs of trouble like warning lights, frayed cables, or discoloration. Periodic diagnostic inspections are more intensive, involving tools to check connection tightness, thermal imagers to find hotspots in cabinets, and multimeters to verify grounding integrity.

Manufacturer Recommendations as a Baseline

Always start with the inspection schedule provided in the equipment's operational manual. However, you must adapt this baseline. A system running 24/7 for production requires a much more frequent and rigorous inspection schedule than an R&D system used a few hours a week.

Building a Robust Inspection Protocol

Your goal is to create a proactive, preventative maintenance culture rather than a reactive, break-fix one. Tailor your inspection focus to your most critical objectives.

- If your primary focus is maximizing uptime and safety: Prioritize frequent, rigorous inspections of the high-power components—the microwave generator, waveguides, and main power feeds.

- If your primary focus is ensuring process repeatability: Concentrate on the control and instrumentation electronics, including all sensor wiring, mass flow controller connections, and vacuum gauge signals.

- If your primary focus is establishing a new maintenance program: Begin by creating a detailed checklist from the manufacturer's manual and then log every inspection to build a reliability history for your specific machine.

Ultimately, consistent and thorough electrical inspection transforms your MPCVD equipment from an unpredictable variable into a reliable and precise tool.

Summary Table:

| Component Category | Key Inspection Items | Purpose |

|---|---|---|

| Microwave Generator & Waveguides | Fault indicators, cooling systems, arcing signs | Plasma generation and stability |

| High-Voltage Power Supplies & Cabling | Cable insulation, connection tightness, overheating | Safety and power delivery |

| Control & Instrumentation Electronics | Dust buildup, signal cables, sensor connections | Process control and repeatability |

| Ancillary System Electrics | Vacuum pump connections, interlock functionality | System integration and safety |

Ensure your MPCVD system operates safely and efficiently with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, tailored to your unique needs. Contact us today to discuss how our deep customization capabilities can enhance your laboratory's performance—reach out via our contact form!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does MPCVD achieve high growth rates for diamond synthesis? Unlock Rapid, High-Quality Diamond Growth

- Why is MPCVD considered a cornerstone of modern materials science and engineering? Unlock High-Purity Materials for Innovation

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production