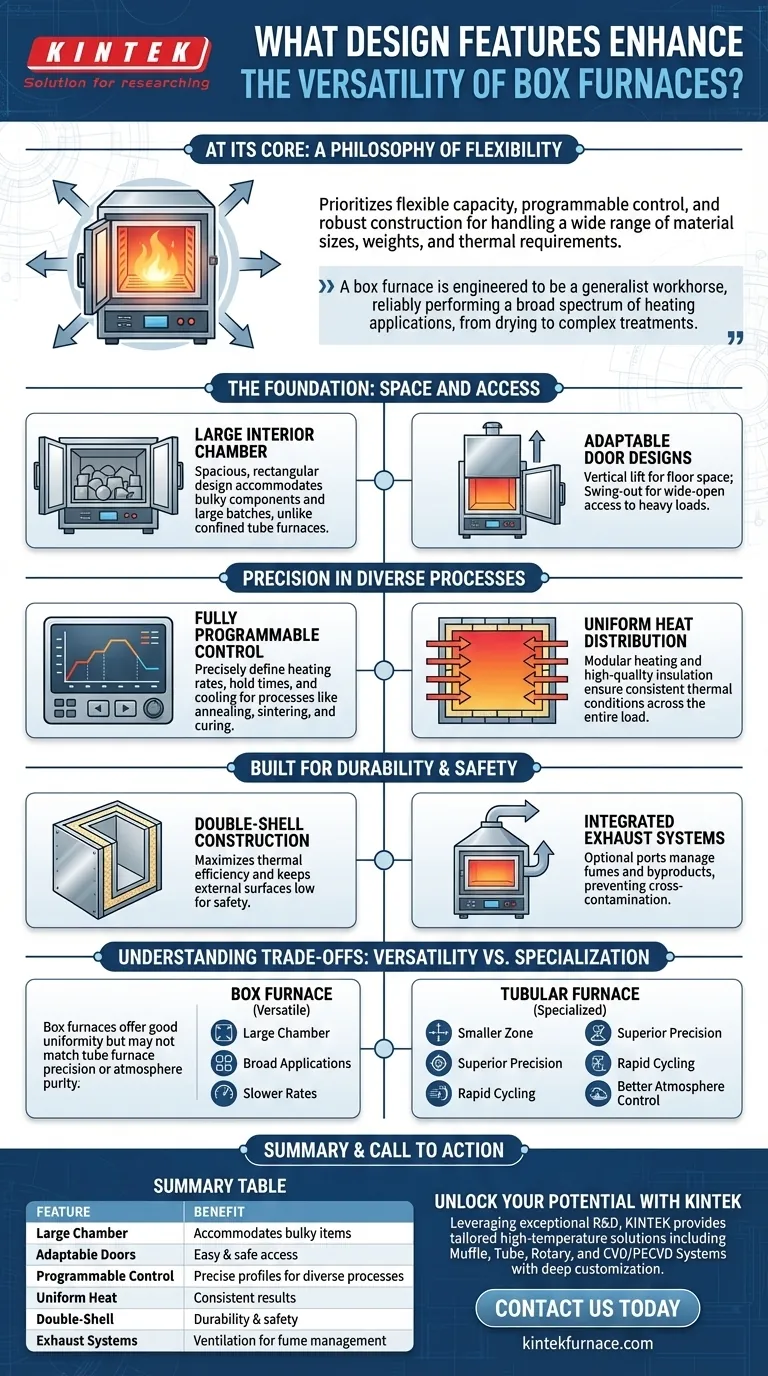

At its core, a box furnace's versatility comes from a deliberate design philosophy that prioritizes flexible capacity, programmable control, and robust construction. Key features include a large interior chamber, adaptable door mechanisms like vertical lift or swing-out designs, and fully programmable controllers that manage heating and cooling rates with high uniformity. This combination allows them to handle a wide range of material sizes, weights, and thermal processing requirements.

A box furnace is engineered to be a generalist workhorse. Its value lies not in mastering a single, specialized task, but in its capacity to reliably perform a broad spectrum of heating applications, from simple drying to complex heat treatments.

The Foundation of Versatility: Space and Access

The most immediate features that enable versatility are the furnace's physical dimensions and how users interact with them. These elements are designed to accommodate unpredictability in sample size and loading requirements.

Large Interior Chamber

A box furnace's defining characteristic is its spacious, rectangular chamber. This large volume is inherently more versatile than the confined space of a tube furnace, allowing it to process bulky components, large batches of smaller items, or materials with irregular shapes.

Adaptable Door Designs

Easy and safe access is critical for usability. Box furnaces typically offer vertical lift doors, which are ideal for conserving floor space and providing a heat shield for the operator, or swing-out doors, which allow for wide-open access when loading heavy or awkward items.

Precision and Repeatability in Diverse Processes

Versatility is useless without control. A box furnace must be able to execute different thermal profiles accurately and repeatedly, which is achieved through its heating and control systems.

Fully Programmable Temperature Control

Modern box furnaces feature fully programmable controllers. This allows operators to precisely define heating rates, hold times at specific temperatures, and controlled cooling rates. This programmability is essential for running different processes like annealing, sintering, curing, or ashing, each with its unique thermal profile.

Uniform Heat Distribution

To ensure consistent results across a large load, uniform temperature is paramount. This is often achieved with modular plate heating elements and high-quality insulation. This design ensures that items placed in the corners of the furnace experience the same thermal conditions as those in the center, a critical factor for process repeatability.

Built for Durability and Safety

A versatile tool must be robust enough to handle varied demands over a long lifespan. The construction and safety features of a box furnace are designed for continuous, reliable operation across many applications.

Double-Shell Construction and Insulation

A double-shell design, combined with energy-saving insulation, serves two purposes. It maximizes thermal efficiency by preventing heat loss, and it keeps the external surface temperatures low, ensuring a safer working environment. This sturdy construction also supports the weight of dense loads.

Integrated Exhaust Systems

Many thermal processes release fumes, moisture, or other byproducts. The inclusion of optional exhaust ports or fume hoods makes the furnace adaptable to these applications, ensuring proper ventilation and preventing cross-contamination between different processes.

Understanding the Trade-offs: Versatility vs. Specialization

No single design is perfect for every task. The versatility of a box furnace comes with specific trade-offs when compared to more specialized equipment.

Temperature Uniformity

While a box furnace offers good temperature uniformity across its large chamber, it may not match the exceptional precision of a tubular furnace. For highly sensitive, small-scale material synthesis or crystal growth, a tube furnace's smaller, symmetrical heating zone often provides superior control.

Atmosphere Control

A box furnace can be equipped with gas ports for modified atmospheres, but achieving a high-purity inert or vacuum environment is significantly more challenging than in a sealed tubular furnace. The large volume and door seals make it difficult to purge and maintain a pure atmosphere.

Heat-Up and Cool-Down Rates

The large thermal mass of a box furnace means it generally heats up and cools down more slowly than a smaller furnace. For applications requiring rapid thermal cycling, this can be a significant limitation.

Making the Right Choice for Your Application

Selecting the right furnace requires matching its design strengths to your primary operational needs.

- If your primary focus is general-purpose lab work or processing varied parts: The large capacity and flexible programming of a box furnace make it the ideal choice.

- If your primary focus is high-purity synthesis with controlled atmospheres: A tubular furnace is better suited for these specialized, small-sample applications.

- If your primary focus is running many simultaneous but separate small experiments: A muffle furnace with a large chamber and multiple shelves can provide the necessary capacity.

Ultimately, understanding these design features empowers you to select the right tool for your specific thermal processing goals.

Summary Table:

| Feature | Benefit |

|---|---|

| Large Interior Chamber | Accommodates bulky items and large batches |

| Adaptable Door Designs | Ensures easy and safe loading access |

| Programmable Temperature Control | Enables precise thermal profiles for diverse processes |

| Uniform Heat Distribution | Provides consistent results across the entire load |

| Double-Shell Construction | Enhances durability and safety with low external temperatures |

| Integrated Exhaust Systems | Allows ventilation for fume and byproduct management |

Unlock the full potential of your thermal processing with KINTEK's advanced box furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our versatile furnaces can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control