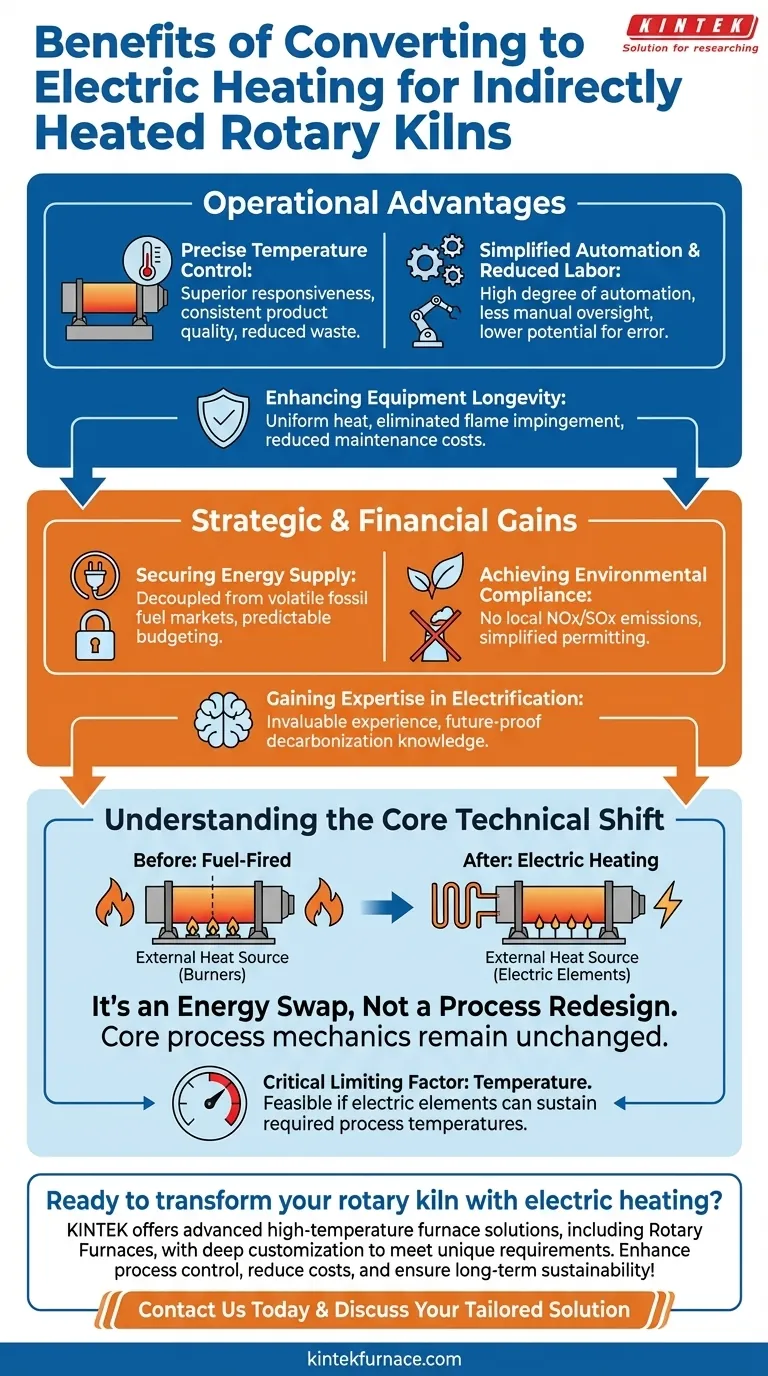

In short, converting an indirectly heated rotary kiln to electric heating delivers significant operational, financial, and strategic advantages. The primary benefits include far more precise temperature control, reduced maintenance costs, a high degree of automation, and improved security of the energy supply by decoupling from volatile fossil fuel markets.

The conversion from fuel-fired to electric heating is less a matter of changing the core process and more a strategic upgrade of the energy system. It unlocks substantial gains in process control, operational cost, and environmental compliance, provided the required process temperatures are achievable with electric elements.

The Operational Advantages of Precise Electric Heat

Transitioning to electric heating fundamentally changes how energy is delivered to the kiln, which brings a cascade of improvements to the day-to-day operation.

Unlocking Superior Temperature Control

Electric heating elements offer a level of responsiveness and precision that is difficult to match with fuel oil or gas combustion.

This high precision in temperature control leads directly to more consistent product quality, reduced material waste, and a more stable, predictable process.

Simplifying Automation and Reducing Labor

The inherent controllability of electricity makes it perfectly suited for a high degree of automation.

This reduces the need for constant manual oversight and adjustment, lowering labor requirements and minimizing the potential for human error.

Enhancing Equipment Longevity

Electric heating can prolong the life of the kiln tube and other critical components.

By providing more uniform heat distribution and eliminating the harsh, localized flame impingement common in fuel-fired systems, electric heating reduces thermal stress and lowers overall maintenance costs.

Strategic and Financial Gains

Beyond the operational floor, electrification provides benefits that impact the entire business, from financial stability to long-term market positioning.

Securing Your Energy Supply

Relying on grid electricity insulates your operation from the price volatility and supply chain disruptions associated with fossil fuels.

This improved security of supply is a critical strategic advantage, allowing for more predictable budgeting and operational planning.

Achieving Environmental Compliance

Because the heating occurs within a closed system without combustion, you eliminate local emissions of pollutants like NOx and SOx.

This not only prevents pollution but also simplifies environmental permitting and ensures compliance with increasingly stringent regulations.

Gaining Expertise in Electrification

Undertaking such a conversion provides the organization with invaluable experience in modern electrification engineering.

This internal knowledge becomes a valuable asset as industries continue to decarbonize and electrify their processes.

Understanding the Core Technical Shift

It's crucial to understand what is—and what is not—changing during this conversion. For an indirectly heated kiln, the change is surprisingly straightforward.

It's an Energy Swap, Not a Process Redesign

In an indirectly heated system, the heat source is external to the process material. Its only job is to supply thermal energy to the kiln shell.

Therefore, the conversion simply involves replacing one external heat source (burners) with another (electric elements). The core process mechanics and chemistry inside the kiln remain unchanged.

The Critical Limiting Factor: Temperature

The primary technical consideration is whether electric heating elements can generate and sustain the required process temperatures.

If the temperature demands of your process are within the operational range of available electric elements, the conversion is technically feasible. If not, this becomes the main barrier to electrification.

Making the Right Choice for Your Operation

Evaluating this conversion requires weighing your primary operational goals against the technical feasibility for your specific process.

- If your primary focus is process control and product quality: The precise, highly adjustable nature of electric heating offers a significant upgrade over traditional fuel firing.

- If your primary focus is long-term cost reduction: The potential for reduced labor, lower maintenance, and extended equipment life makes electrification a compelling financial case.

- If your primary focus is strategic resilience and sustainability: Securing your energy supply and eliminating local emissions provides a clear, long-term competitive advantage.

Ultimately, electrifying your rotary kiln is a strategic investment in a more controlled, efficient, and resilient future for your process.

Summary Table:

| Benefit Category | Key Advantages |

|---|---|

| Operational | Precise temperature control, uniform heating, reduced labor, automation |

| Financial | Lower maintenance costs, predictable energy pricing, extended equipment life |

| Strategic | Energy supply security, environmental compliance, decarbonization expertise |

| Technical | Simplified energy swap, no process redesign, temperature feasibility check |

Ready to transform your rotary kiln with electric heating? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your process control, reduce costs, and ensure long-term sustainability!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing