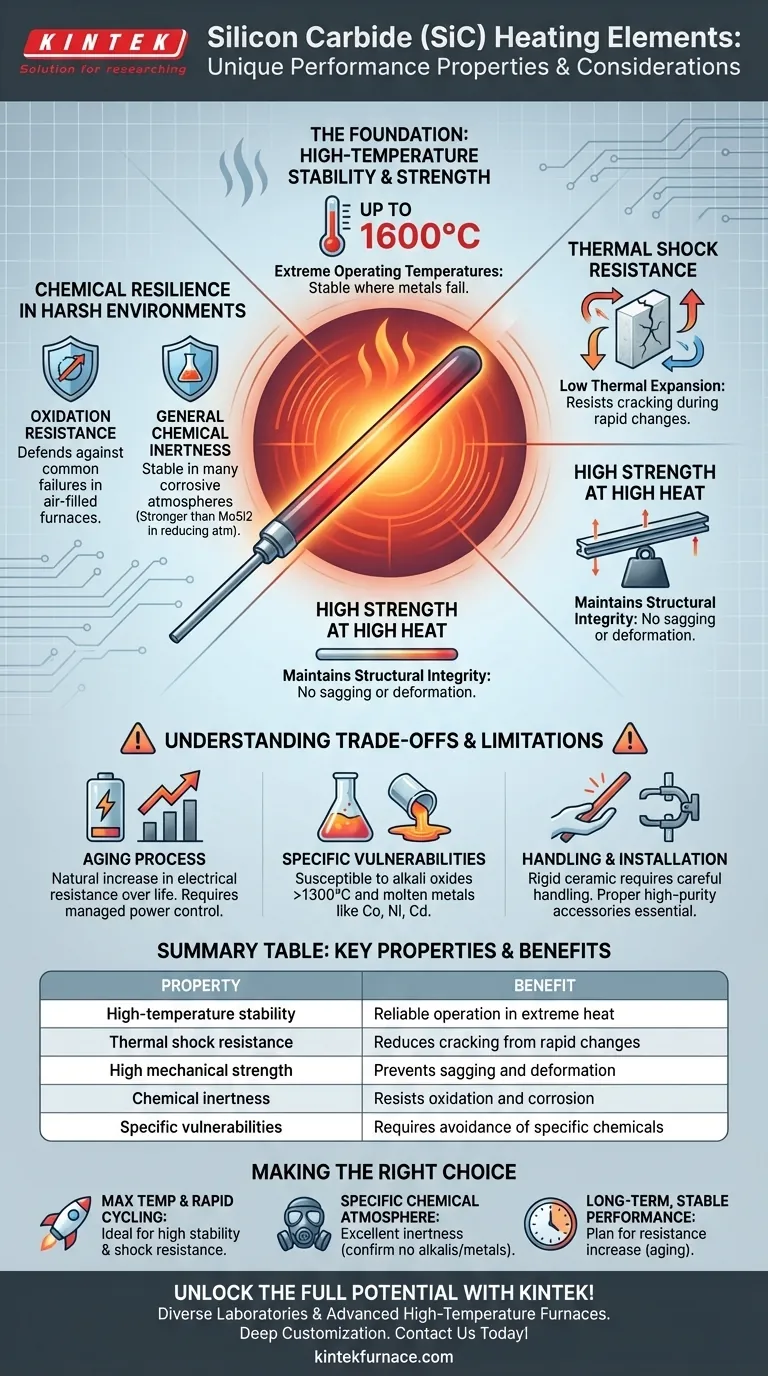

At their core, silicon carbide (SiC) heating elements derive their exceptional performance from a unique combination of material properties. These include the ability to operate at extremely high temperatures (up to 1600°C), excellent resistance to thermal shock, high mechanical strength, and general chemical inertness, which together ensure a long and reliable operational life in demanding industrial environments.

The true value of Silicon Carbide lies not in a single property, but in its synergistic combination of high-temperature stability and physical durability. This makes it a uniquely reliable solution for intense heating processes, provided its specific chemical and electrical aging characteristics are properly managed.

The Foundation: High-Temperature Stability and Strength

The primary advantage of SiC elements is their ability to perform where traditional metallic elements fail. This capability is built on several key material characteristics.

Extreme Operating Temperatures

Silicon carbide is fundamentally stable at very high temperatures. This allows it to operate reliably in furnaces reaching up to 1600°C, far exceeding the limits of most metal-based heating elements.

Resistance to Thermal Shock

SiC has a very low coefficient of thermal expansion. This means it expands and contracts very little during rapid heating and cooling cycles, which dramatically reduces internal mechanical stress and prevents cracking.

High Strength at High Heat

Unlike many materials that soften or deform at high temperatures, SiC maintains its structural integrity and high strength. This ensures the element does not sag or break under its own weight during operation.

Chemical Resilience in Harsh Environments

Beyond physical durability, SiC's chemical makeup provides a robust defense against many corrosive industrial atmospheres, further extending its lifespan.

Superior Resistance to Oxidation

The material is highly resistant to oxidation, one of the most common failure modes for heating elements in high-temperature, air-filled furnaces.

General Chemical Inertness

SiC remains stable and non-reactive in many harsh chemical environments. It is particularly noted for being stronger than alternatives like Molybdenum Disilicide (MoSi2) in reducing atmospheres.

Understanding the Trade-offs and Limitations

No material is perfect. To use SiC elements effectively, you must understand their operational limitations and vulnerabilities.

The Challenge of Aging

Over their operational life, SiC elements experience a natural increase in their electrical resistance. This aging process is a critical factor that must be managed by the power control system to ensure consistent heat output and prevent overheating.

Specific Chemical Vulnerabilities

While generally inert, SiC is susceptible to certain chemicals at high temperatures. Alkali and alkaline oxides will react with SiC above 1300°C, forming silicates that reduce heating efficiency.

Furthermore, direct contact with certain molten metals, including cobalt, nickel, and cadmium, will actively corrode the element and significantly shorten its lifespan.

Installation and Handling

As a rigid ceramic material, SiC requires careful handling. Proper installation depends on specific accessories like high-purity aluminum connecting belts and stainless steel fixing fixtures to secure the rods and ensure good electrical contact without creating stress points.

Making the Right Choice for Your Application

Understanding these properties allows you to correctly specify SiC elements for your process.

- If your primary focus is maximum temperature and rapid cycling: SiC is an ideal choice due to its high-temperature stability and outstanding resistance to thermal shock.

- If your primary focus is operating in a specific chemical atmosphere: SiC offers excellent inertness, but you must first confirm your process is free from high-temperature alkali oxides or corrosive molten metals.

- If your primary focus is long-term, stable performance: Plan your power supply and control system to accommodate the gradual increase in resistance that is characteristic of SiC element aging.

By aligning the unique strengths and known limitations of silicon carbide with your specific operational needs, you can ensure a reliable and efficient high-temperature process.

Summary Table:

| Property | Benefit |

|---|---|

| High-temperature stability (up to 1600°C) | Enables reliable operation in extreme heat environments |

| Excellent thermal shock resistance | Reduces cracking from rapid temperature changes |

| High mechanical strength at high heat | Prevents sagging and maintains structural integrity |

| Chemical inertness | Resists oxidation and corrosion in harsh atmospheres |

| Specific vulnerabilities | Requires avoidance of alkali oxides and certain molten metals |

Unlock the full potential of silicon carbide heating elements with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your high-temperature processes and ensure reliable performance in demanding environments.

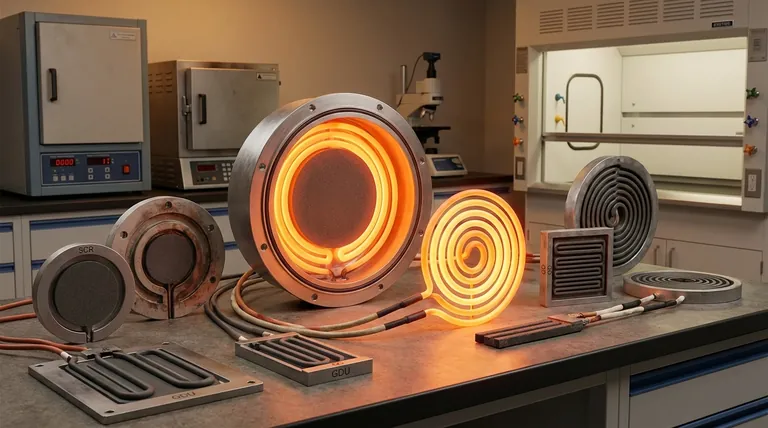

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance