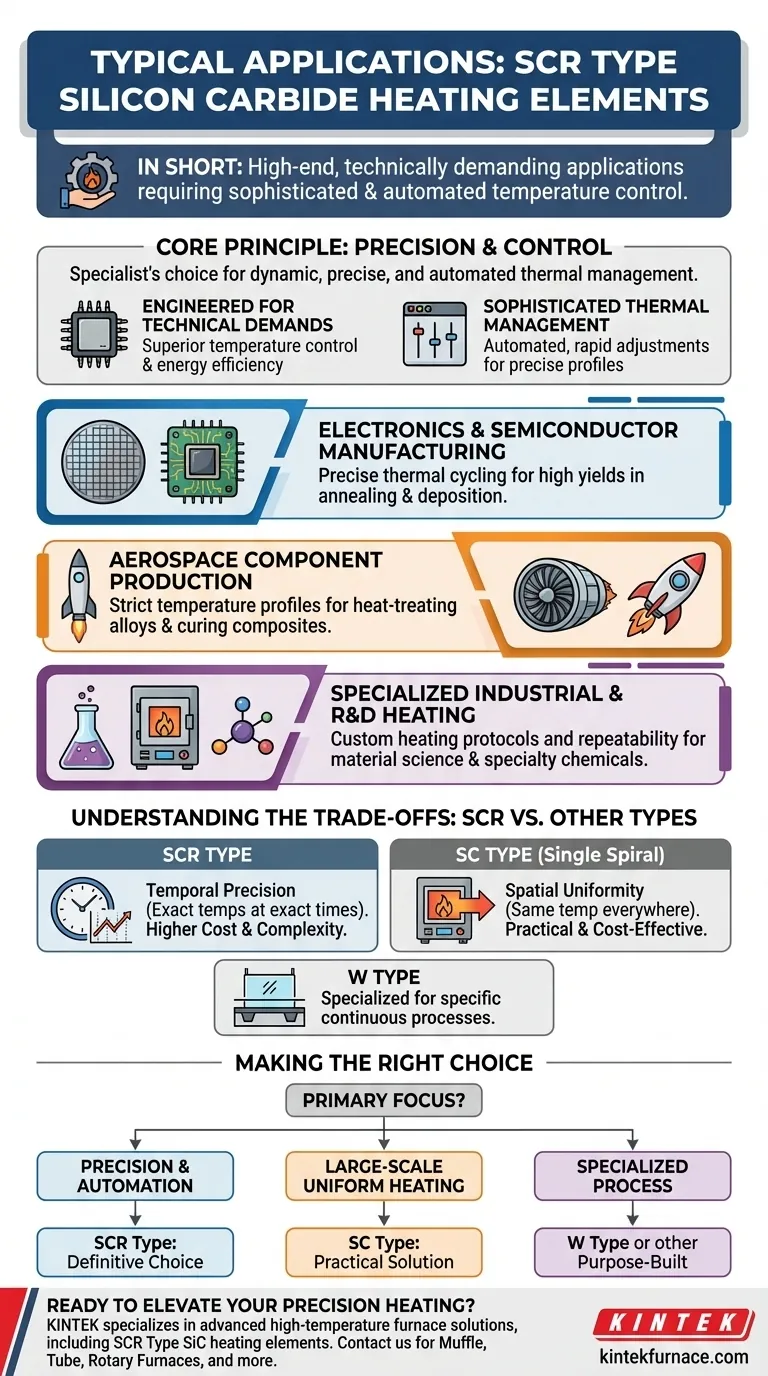

In short, SCR Type Silicon Carbide (SiC) heating elements are used in high-end, technically demanding applications that require sophisticated and automated temperature control. Their primary applications are found in advanced electronics manufacturing, aerospace component production, and specialized industrial heating processes where precision is paramount.

The decision to use an SCR Type element is less about the industry and more about the process requirement. They are the specialist's choice for applications where dynamic, precise, and automated thermal management is not just a benefit, but a critical necessity for success.

The Core Principle of SCR Elements: Precision and Control

SCR Type SiC elements are not general-purpose heaters. They are engineered for scenarios where standard heating elements lack the required responsiveness and accuracy.

Engineered for Technical Demands

The SCR design is a calculated enhancement of other SiC element types, specifically optimized for superior temperature control and energy efficiency. This makes them ideal for the most technically demanding heating cycles.

The Need for Sophisticated Thermal Management

These elements are almost always paired with advanced control systems. Their value is fully realized in environments where automated and rapid temperature adjustments are necessary to follow a precise heating profile.

Primary Applications of the SCR Type

The common thread across all SCR applications is the intolerance for thermal deviation. The material or process is highly sensitive to temperature, and any error could lead to component failure or a compromised final product.

Advanced Electronics & Semiconductor Manufacturing

The production of silicon wafers, integrated circuits, and other electronic components involves multiple stages of precise thermal cycling. SCR elements provide the exact temperature profiles needed for processes like annealing and deposition, ensuring high yields and component reliability.

Aerospace Component Production

Manufacturing parts for the aerospace industry often involves heat-treating exotic alloys or curing advanced composites. The final mechanical properties of these materials are directly dependent on adhering to a strict, pre-defined temperature and time curve, a task perfectly suited for SCR elements.

Specialized Industrial and R&D Heating

This category includes laboratory furnaces, material science research, and the production of specialty chemicals or ceramics. In these environments, processes are often complex and require the ability to create and repeat highly specific heating protocols with absolute certainty.

Understanding the Trade-offs: SCR vs. Other SiC Types

Choosing an SCR element means prioritizing precision, often over other factors. Understanding its place relative to other common SiC types is crucial for making an informed decision.

Compared to SC Type Elements

The SC (Single Spiral) Type is the workhorse for large-scale industrial furnaces. It excels at providing consistent, uniform heat across a large area, making it perfect for metal treatment (annealing, hardening) and large-batch ceramics.

SC focuses on spatial uniformity (the same temperature everywhere), while SCR excels at temporal precision (hitting exact temperatures at exact times).

Compared to W Type Elements

The W Type is another specialist element, often used in float glass manufacturing and certain chemical processes. Its robust, three-phase design is optimized for efficiency and stability in those specific, continuous high-temperature environments.

The Cost and Complexity Factor

The sophisticated design and control capabilities of SCR elements come at a higher initial cost. They also require a more advanced control infrastructure (like SCR power controllers) to leverage their full potential, adding to system complexity. This is a trade-off for their unparalleled performance in demanding applications.

Making the Right Choice for Your Application

Selecting the correct heating element requires aligning the element's strengths with your primary process goal.

- If your primary focus is precision and automation: SCR Type elements are the definitive choice for sensitive materials that demand dynamic, automated, and highly accurate temperature profiles.

- If your primary focus is large-scale uniform heating: The SC Type is the more practical and cost-effective solution for large furnaces in metal treatment or ceramics where stable, even heat is the goal.

- If your primary focus is a specialized process like float glass: You should investigate other purpose-built elements, such as the W Type, which are designed for that specific industrial application.

Ultimately, choosing the right element is about matching the tool to the technical demands of your specific heating task.

Summary Table:

| Application Area | Key Features | Ideal For |

|---|---|---|

| Electronics & Semiconductor Manufacturing | Precise thermal cycling, automated control | Annealing, deposition processes for high yields |

| Aerospace Component Production | Strict temperature profiles, reliability | Heat-treating alloys, curing composites |

| Specialized Industrial & R&D Heating | Custom heating protocols, repeatability | Labs, material science, specialty chemicals |

Ready to elevate your precision heating processes? KINTEK specializes in advanced high-temperature furnace solutions, including SCR Type SiC heating elements. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our solutions can enhance your efficiency and accuracy in demanding applications like electronics, aerospace, and R&D.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights