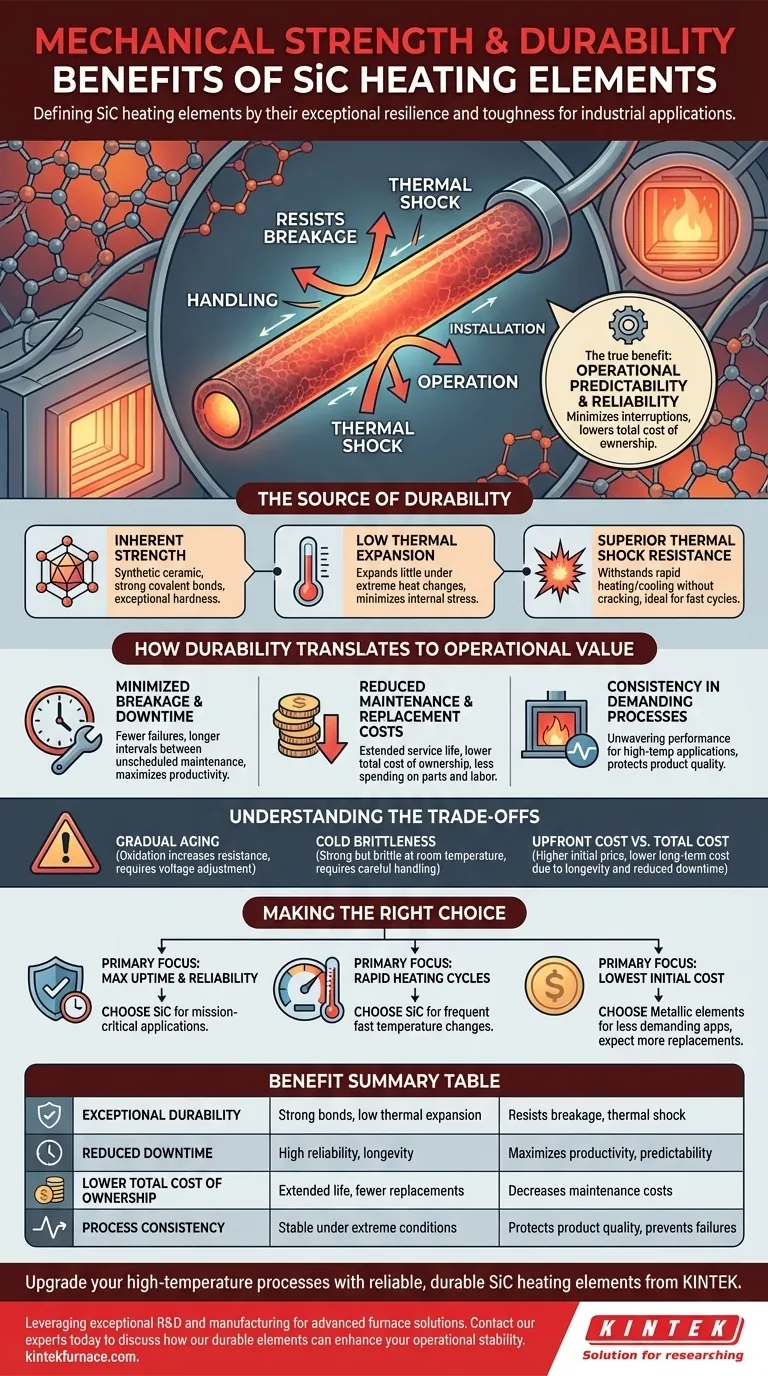

In short, Silicon Carbide (SiC) heating elements are defined by their exceptional mechanical strength and durability. This inherent toughness makes them highly resistant to breakage during handling, installation, and operation. As a result, they significantly reduce the frequency of replacements and the associated maintenance costs and operational downtime common with more fragile heating elements.

The true benefit of SiC's mechanical strength is not just its physical toughness, but its contribution to operational predictability. By resisting thermal shock and physical stress, these elements provide a level of reliability that minimizes costly production interruptions and lowers the total cost of ownership.

The Source of SiC's Durability

The remarkable durability of SiC heating elements is not a single feature but a result of its fundamental material properties. Understanding these properties is key to appreciating their value in demanding industrial environments.

The Inherent Strength of the Material

Silicon carbide is a synthetic ceramic material formed by strong covalent bonds. This atomic structure gives it exceptional hardness and physical strength, making it inherently more robust than many alternative materials.

Low Coefficient of Thermal Expansion

This is the most critical factor for durability in heating applications. SiC elements expand and contract very little when subjected to extreme temperature changes. This property minimizes the buildup of internal stress during heating and cooling cycles.

Superior Thermal Shock Resistance

The direct result of low thermal expansion is an outstanding resistance to thermal shock. The element can withstand rapid heating and cooling rates that would cause other, more brittle ceramics to crack and fail. This is crucial for processes that require fast cycles.

How Durability Translates to Operational Value

The physical properties of SiC create tangible benefits that impact efficiency, cost, and output. For any high-temperature operation, reliability is paramount.

Minimized Breakage and Downtime

Fewer failures mean less unscheduled downtime. Because SiC elements are less prone to breaking from thermal shock or physical vibration, furnaces and kilns can run for longer, more predictable intervals, maximizing productivity.

Reduced Maintenance and Replacement Costs

The longevity of SiC elements directly lowers the total cost of ownership. While the initial investment may be higher than some alternatives, their extended service life means you spend less on replacement parts and the labor required to install them.

Consistency in Demanding Processes

High-temperature processes like sintering, melting, and heat treating require unwavering performance. The reliability of SiC ensures that heat is delivered consistently, protecting the quality of the end product and preventing costly batch failures due to element malfunction.

Understanding the Trade-offs

No material is perfect for every situation. Objectivity requires acknowledging the operational considerations that come with using SiC elements.

Gradual Aging Through Oxidation

While mechanically robust, SiC elements do age. Over hundreds or thousands of hours at high temperatures, the element's surface slowly oxidizes. This process increases its electrical resistance, which must be compensated for by increasing the voltage to maintain the same power output.

Brittleness When Cold

Like most advanced ceramics, SiC elements are strong but can be brittle at room temperature. They can be damaged or shattered by sharp mechanical impacts, which requires careful handling during installation and maintenance.

Upfront Cost vs. Total Cost

SiC heating elements typically have a higher initial purchase price compared to metallic elements like Kanthal (FeCrAl). The economic justification rests entirely on a lower total cost of ownership, factoring in their longer life and the high cost of process downtime.

Making the Right Choice for Your Process

Your decision should be based on a clear understanding of your primary operational goal.

- If your primary focus is maximum uptime and reliability: SiC is the definitive choice for mission-critical applications where furnace downtime leads to significant financial loss.

- If your primary focus is rapid heating cycles: The superior thermal shock resistance of SiC makes it ideal for processes requiring frequent and fast temperature changes.

- If your primary focus is the lowest possible initial cost: Metallic elements may be suitable for less demanding, lower-temperature applications, but expect more frequent replacements and a shorter service life.

Choosing the right heating element is an investment in your operational stability and long-term success.

Summary Table:

| Benefit | Key Feature | Impact |

|---|---|---|

| Exceptional Durability | Strong covalent bonds, low thermal expansion | Resists breakage and thermal shock |

| Reduced Downtime | High reliability and longevity | Maximizes productivity and operational predictability |

| Lower Total Cost of Ownership | Extended service life, fewer replacements | Decreases maintenance and replacement costs |

| Process Consistency | Stable performance under extreme conditions | Protects product quality and prevents batch failures |

Upgrade your high-temperature processes with reliable, durable SiC heating elements from KINTEK.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

If your primary focus is maximizing uptime and ensuring process consistency in demanding applications like sintering or heat treating, our SiC heating element solutions are designed to deliver the reliability you need.

Contact our experts today to discuss how our durable heating elements can enhance your operational stability and long-term success.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability