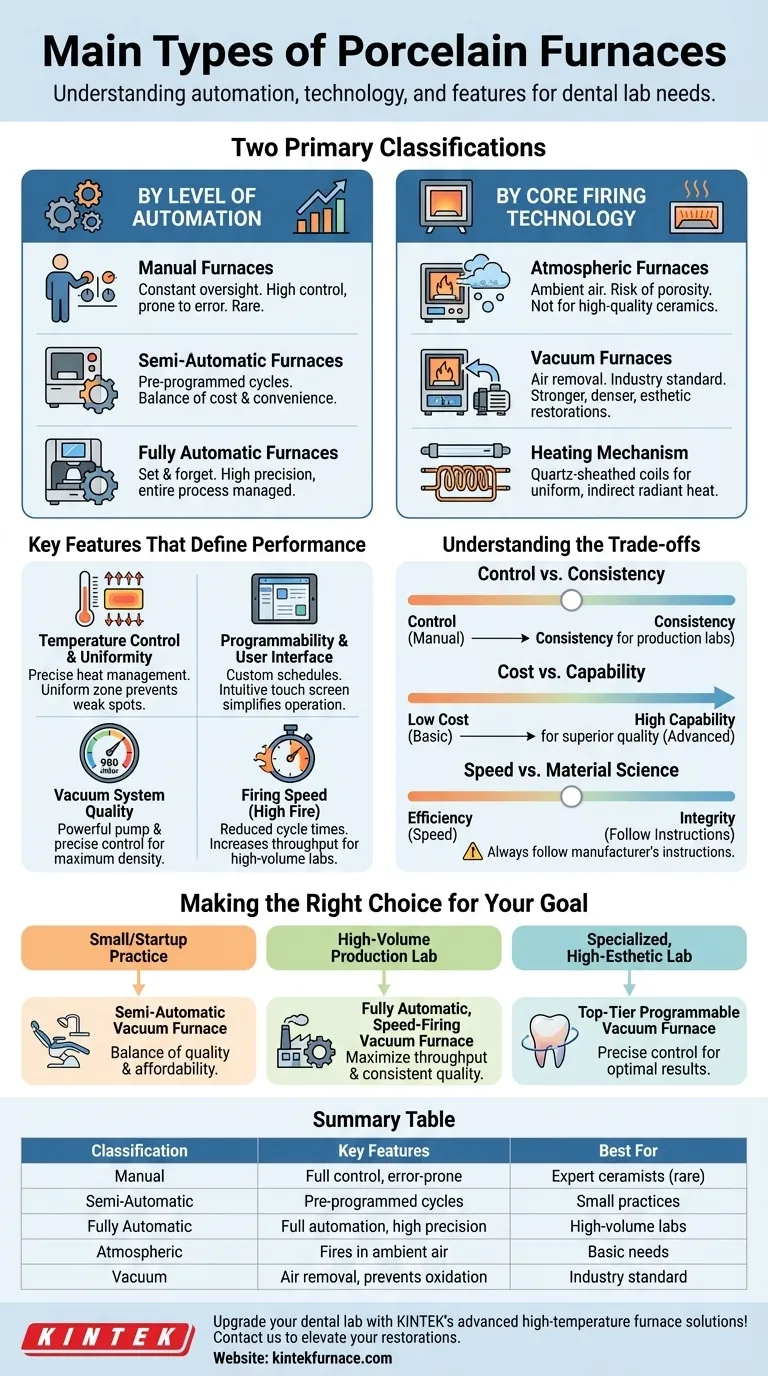

At its core, a porcelain furnace is classified in two primary ways: by its level of automation and by its core firing technology. Modern furnaces are almost all electric, but they range from manual models requiring constant oversight to fully automatic, programmable vacuum furnaces that ensure the highest quality restorations with minimal user input.

Understanding the types of porcelain furnaces is not about choosing a single category, but about recognizing how different features—automation, vacuum capability, and programmability—combine to meet specific clinical and laboratory needs for quality, consistency, and throughput.

The Primary Ways to Classify Porcelain Furnaces

To make an informed decision, you must evaluate furnaces across two key axes: how they operate and the technology they use to fire the porcelain.

By Level of Automation

The level of automation directly impacts workflow, consistency, and the need for operator expertise.

- Manual Furnaces: These require the operator to monitor and adjust the temperature and timing throughout the firing cycle. They offer maximum control for experts but are prone to human error and are rarely used in modern production settings.

- Semi-Automatic Furnaces: These offer pre-programmed cycles for common tasks, but may still require some manual steps, such as initiating the vacuum or advancing the cycle. They represent a balance between cost and convenience.

- Fully Automatic Furnaces: These are the standard for most modern labs. The operator simply selects a program, and the furnace manages the entire process—including pre-heating, temperature ramps, vacuum application, and cooling—with high precision.

By Core Firing Technology

The internal environment of the furnace is the most critical factor for the final quality of the ceramic restoration.

- Atmospheric Furnaces: These are simpler units that fire porcelain in ambient air. They are not suitable for the high-quality, dense restorations required by modern dental ceramics, which can suffer from porosity and discoloration when fired in oxygen.

- Vacuum Furnaces: This is the industry standard. By removing air from the muffle (heating chamber) during the firing cycle, these furnaces prevent oxygen from interfering with the porcelain. This process results in stronger, denser, and more esthetic restorations with fewer bubbles or pits.

- Heating Mechanism: Most high-quality furnaces use quartz-sheathed heating coils. The quartz tube protects the restoration from direct contact with the heating element, ensuring clean, uniform radiant heat. This is a form of indirect heating that is critical for consistent results.

Key Features That Define Performance

Beyond the broad classifications, specific technical features are what truly differentiate a basic furnace from a high-performance one.

Temperature Control and Uniformity

The single most important function of a furnace is precise heat management. A uniform heating zone within the muffle ensures the entire restoration is fired at the same temperature, preventing weak spots or discoloration. Advanced controllers allow for multi-stage programs with precise temperature ramp rates.

Programmability and User Interface

Modern furnaces are defined by their software. The ability to create and store custom firing schedules is essential for working with the vast array of ceramic materials on the market. A clear, intuitive interface, often a color touch screen, simplifies operation and reduces the risk of error.

Vacuum System Quality

Not all vacuum systems are equal. A high-performance furnace will have a powerful pump and precise controller capable of achieving and holding a specific vacuum level (e.g., 980 mBar). This ensures complete air removal for maximum porcelain density.

Firing Speed ("High Fire")

Some advanced furnaces are marketed as "high fire" or "speed" furnaces. They use advanced heating elements and software to significantly reduce firing cycle times. This feature is a major advantage for high-volume labs looking to increase throughput.

Understanding the Trade-offs

Choosing a furnace involves balancing capability, cost, and workflow requirements.

Control vs. Consistency

A fully automatic, programmable furnace provides unmatched consistency and repeatability, which is vital for a production lab. However, a master ceramist doing highly artistic, one-off cases might prefer the granular control offered by a more manual process, though this is increasingly rare.

Cost vs. Capability

There is a direct correlation between price and features. A basic, semi-automatic atmospheric furnace will have a low entry cost. A fully automatic, programmable vacuum furnace with speed-firing capabilities is a significant investment but delivers superior quality, efficiency, and material compatibility.

Speed vs. Material Science

While speed-firing is an excellent feature for efficiency, not all ceramic materials are designed to be fired rapidly. Firing a material outside of its recommended parameters can compromise its structural integrity and esthetics. Always follow the ceramic manufacturer's instructions.

Making the Right Choice for Your Goal

Your decision should be driven by the primary demands of your work.

- If your primary focus is a small or startup dental practice: A reliable, semi-automatic vacuum furnace with some key pre-set programs offers a good balance of quality and affordability.

- If your primary focus is a high-volume production lab: A fully automatic, programmable vacuum furnace with speed-firing capabilities is essential for maximizing throughput and ensuring consistent quality.

- If your primary focus is specialized, high-esthetic restorations: A top-tier programmable vacuum furnace with precise temperature and vacuum control is non-negotiable to achieve optimal results with advanced ceramic systems.

Ultimately, the right furnace is the one that reliably and consistently executes the firing parameters required by the materials you use.

Summary Table:

| Classification | Key Features | Best For |

|---|---|---|

| Manual Furnaces | Full operator control, prone to error | Expert ceramists, rare use |

| Semi-Automatic Furnaces | Pre-programmed cycles, some manual steps | Small practices, cost-effective balance |

| Fully Automatic Furnaces | Full automation, high precision | High-volume labs, consistent results |

| Atmospheric Furnaces | Fires in ambient air, risk of porosity | Basic needs, not for high-quality ceramics |

| Vacuum Furnaces | Air removal, prevents oxidation, dense restorations | Industry standard, superior quality |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering enhanced consistency, efficiency, and material compatibility. Contact us today to discuss how our furnaces can elevate your restorations and boost productivity!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations