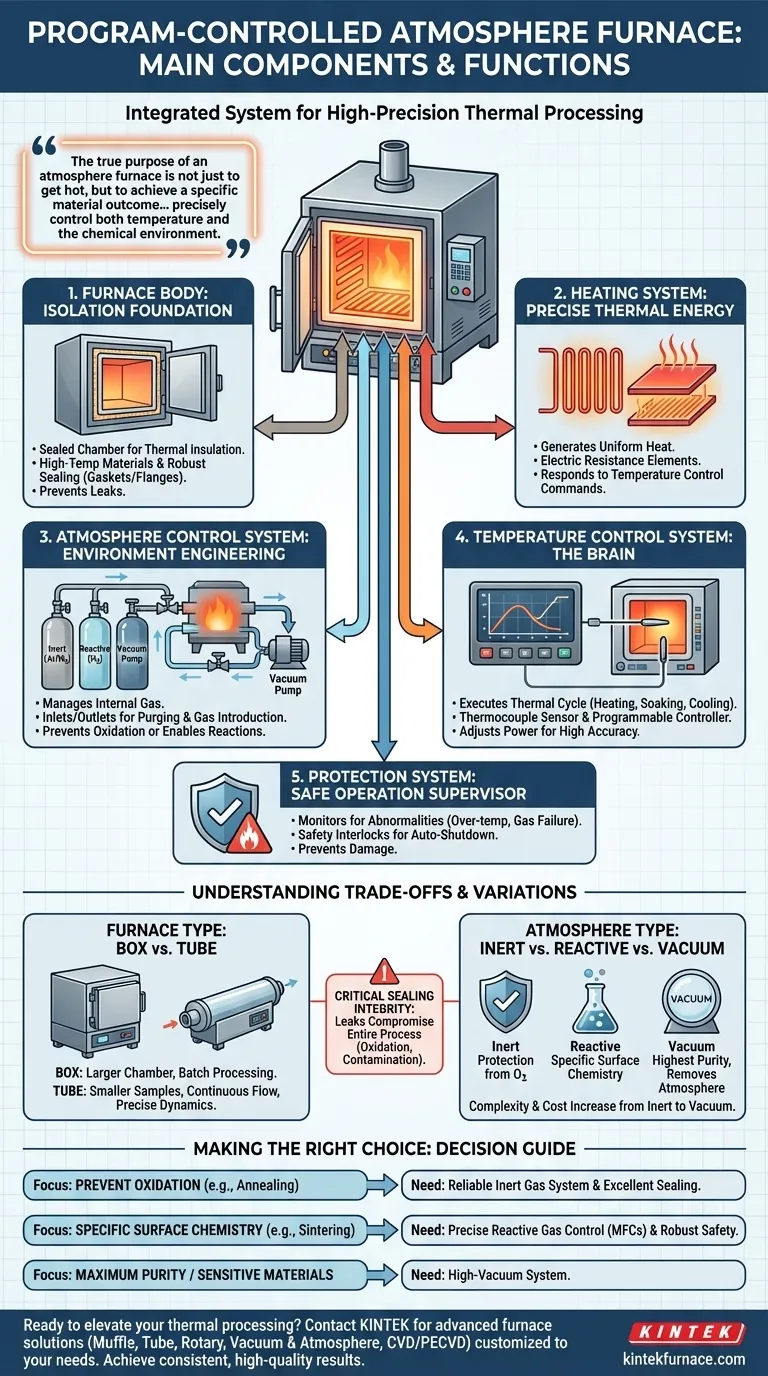

At its core, a program-controlled atmosphere furnace is an integrated system designed for high-precision thermal processing. Its main components are the furnace body which provides a sealed chamber, a heating system to generate high temperatures, an atmosphere control system to manage the internal gas environment, and a temperature control system to execute precise heating and cooling profiles.

The true purpose of an atmosphere furnace is not just to get hot, but to achieve a specific material outcome. This is only possible when its components work in concert to precisely control both temperature and the chemical environment, preventing unwanted reactions like oxidation.

The Anatomy of Control: Deconstructing the Furnace

To understand how these furnaces achieve such precise results, we must look at each major component system and its specific function. They are not independent parts but a cohesive unit.

The Furnace Body: The Foundation of Isolation

The furnace body, or chamber, is the physical structure that contains the process. It is typically a box or tube shape.

Its primary role is twofold: thermal insulation to retain heat efficiently and providing a sealed enclosure to contain the controlled atmosphere. This requires high-temperature-resistant materials and robust sealing mechanisms, such as silicone gaskets or welded flanges, to prevent leaks.

The Heating System: Generating Precise Thermal Energy

The heating system is responsible for generating the required heat. This is most often accomplished with electric resistance elements, such as heating wires or silicon carbide plates, positioned to ensure uniform temperature distribution.

While these elements create the heat, they do not control it. Their job is simply to respond to the commands sent by the temperature control system.

The Atmosphere Control System: Engineering the Environment

This is the defining feature of an atmosphere furnace. The atmosphere control system manages the gas inside the chamber to create a specific chemical environment.

It consists of gas inlets and outlets that allow for purging the chamber of ambient air and introducing a desired gas. This can be an inert gas like Argon or Nitrogen to prevent oxidation, or a reactive gas like Hydrogen to participate in a chemical process like reduction or brazing.

The Temperature Control System: The Brain of the Operation

The temperature control system governs the entire thermal cycle. It uses a sensor, typically a thermocouple, to measure the internal temperature in real-time.

This information is fed to a programmable controller, which compares the actual temperature to the desired setpoint in the program. It then adjusts the power to the heating elements to follow the pre-programmed heating, soaking, and cooling ramps with high accuracy.

The Protection System: Ensuring Safe Operation

Finally, a protection system acts as a safety supervisor. It monitors for abnormal conditions, such as over-temperature events or failures in the gas system.

This system often includes safety interlocks that can shut down the furnace to prevent damage to the equipment, the material being processed, or the facility.

Understanding the Trade-offs and Variations

Not all atmosphere furnaces are built the same. The specific design depends heavily on the intended application, leading to important trade-offs.

Furnace Type: Box vs. Tube

The physical shape of the furnace is a primary differentiator. A box-type furnace offers a larger chamber, ideal for processing batches of parts or larger individual components.

A tube furnace uses a cylindrical chamber, which is better suited for smaller samples, continuous processing where materials are pushed through the tube, or applications requiring very precise gas flow dynamics.

Atmosphere Type: Inert vs. Reactive vs. Vacuum

The complexity of the atmosphere system is a major cost and performance factor. An inert gas system is the most common, designed purely for protection from oxygen.

A reactive gas system is more complex, often requiring mass flow controllers to mix gases for processes like carburizing. A vacuum furnace, a close relative, uses pumps to remove nearly all atmosphere, offering the highest level of purity but at a significantly higher cost and complexity.

The Critical Role of Sealing Integrity

A common point of failure is the seal. A small leak in a door gasket or a fitting can compromise the entire process by allowing oxygen or moisture to enter the chamber. This undermines the purpose of the atmosphere control system, leading to oxidation, contamination, and inconsistent results.

Making the Right Choice for Your Application

The ideal furnace configuration depends entirely on your material processing goals. Your choice of components should be driven by the specific outcome you need to achieve.

- If your primary focus is preventing oxidation on standard materials (e.g., annealing): A furnace with a reliable inert gas system (Nitrogen or Argon) and excellent sealing is your most critical requirement.

- If your primary focus is achieving specific surface chemistry (e.g., sintering with binders): You need a precise reactive gas control system, potentially with mass flow controllers and a robust safety protocol.

- If your primary focus is processing highly sensitive materials or achieving maximum purity: A high-vacuum system is necessary to eliminate nearly all atmospheric contaminants before backfilling with a high-purity process gas.

Understanding how these components function as an integrated system is the key to achieving consistent, high-quality results in your thermal processes.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Body | Provides sealed chamber for thermal insulation | High-temperature materials, robust sealing |

| Heating System | Generates and distributes heat uniformly | Electric resistance elements, uniform heating |

| Atmosphere Control System | Manages internal gas environment | Gas inlets/outlets, inert or reactive gases |

| Temperature Control System | Executes precise heating/cooling profiles | Thermocouple sensor, programmable controller |

| Protection System | Ensures safe operation and prevents damage | Safety interlocks, monitors for abnormalities |

Ready to elevate your thermal processing with precision? Contact KINTEK today to discuss how our advanced high-temperature furnace solutions—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—can be customized to meet your unique experimental needs. Leveraging exceptional R&D and in-house manufacturing, we ensure reliable performance and tailored designs for diverse laboratories. Get in touch now to achieve consistent, high-quality results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment