In short, a vacuum furnace provides unparalleled control and purity for heat treatment. By removing the atmosphere from the heating chamber, it fundamentally prevents oxidation and other unwanted chemical reactions. This results in superior material quality, precise temperature uniformity, rapid cooling capabilities, and the ability to produce perfectly consistent, repeatable results.

The core problem with traditional heat treatment is the unpredictable effect of the atmosphere on the material. A vacuum furnace solves this by removing the atmosphere entirely, transforming the process from an approximation into a predictable science that guarantees material integrity and consistency.

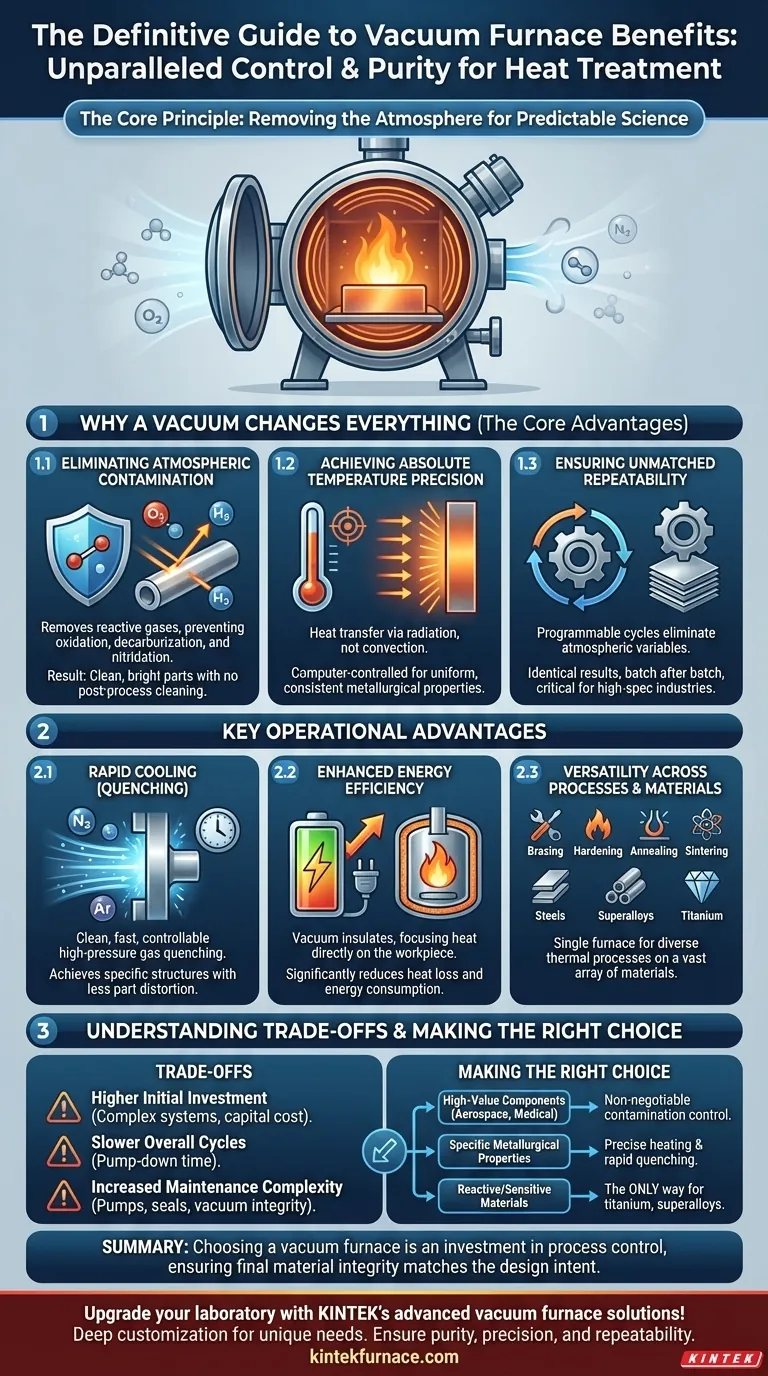

The Core Principle: Why a Vacuum Changes Everything

Removing air and other gases from the heating chamber is the central advantage that drives all other benefits. This creates an inert environment that is impossible to achieve in a conventional atmospheric furnace.

Eliminating Atmospheric Contamination

The most critical benefit of a vacuum is the prevention of reactions between the hot material and atmospheric gases. By pumping the chamber down to a near-perfect vacuum, reactive gases like oxygen and hydrogen are almost entirely removed.

This directly prevents oxidation, decarburization, and nitridation, which can compromise a material's surface and structural integrity. The result is a bright, clean part that requires no post-process cleaning, such as sandblasting or pickling.

Achieving Absolute Temperature Precision

A vacuum is an excellent insulator. In an atmospheric furnace, heat is transferred unevenly through convection currents in the air, creating hot and cold spots. In a vacuum, heat transfer occurs primarily through radiation, which is far more uniform.

Combined with modern computer-controlled heating elements, this allows for extremely precise temperature management across the entire workpiece. This uniformity is critical for ensuring consistent metallurgical properties throughout the part.

Ensuring Unmatched Process Repeatability

Because the process environment is free from atmospheric variables, every cycle can be programmed to run identically. The heating rates, soak times, temperature levels, and cooling rates are managed by a controller, not chance.

This computer-controlled precision ensures that the results of the first batch are identical to the last. For high-specification industries like aerospace and medical devices, this level of repeatability is not a luxury—it is a requirement.

Key Operational Advantages

Beyond creating a pure environment, the design of a vacuum furnace offers distinct operational benefits that improve process speed, efficiency, and flexibility.

The Power of Rapid Cooling (Quenching)

After the heating cycle, a vacuum furnace can rapidly cool the material by backfilling the chamber with a high-pressure inert gas like nitrogen or argon. This high-pressure gas quenching is clean, fast, and highly controllable.

It allows for precise control over the cooling rate to achieve specific metallurgical structures and hardness, often with less part distortion than traditional oil or water quenching.

Enhanced Energy Efficiency

The vacuum's insulating properties mean that heat energy is focused directly on the workpiece instead of being lost to the surrounding air. This dramatically reduces heat loss and minimizes energy consumption compared to atmospheric furnaces, which constantly radiate heat into the surrounding environment.

Versatility Across Materials and Processes

A single vacuum furnace can be used for a wide range of thermal processes, including brazing, hardening, annealing, tempering, and sintering. Its inert environment makes it suitable for processing a vast array of materials, from standard steels to highly reactive superalloys, titanium, and advanced ceramics.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for all heat treatment needs. Understanding its limitations is key to making an informed decision.

Higher Initial Investment

Vacuum furnaces are complex systems with sophisticated pumps, seals, chambers, and control systems. This results in a significantly higher upfront capital cost compared to simpler atmospheric furnaces.

Slower Overall Cycle Times

While the heating and cooling can be rapid, every cycle requires time to pump the chamber down to the target vacuum level. For high-volume, low-margin parts, this pump-down time can make the overall cycle longer than a continuous atmospheric process.

Increased Maintenance Complexity

The integrity of the vacuum is paramount. This requires regular, specialized maintenance of pumps, seals, valves, and diagnostic instruments to prevent leaks and ensure consistent performance. This maintenance is more demanding than that required for most atmospheric furnaces.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your quality requirements, materials, and production goals.

- If your primary focus is high-value components (aerospace, medical): The contamination control and process repeatability of a vacuum furnace are non-negotiable for meeting strict quality standards.

- If your primary focus is achieving specific metallurgical properties: The precise control over heating and rapid gas quenching provides unmatched power to engineer the final material characteristics.

- If your primary focus is processing reactive or sensitive materials: The inert environment is the only way to effectively heat-treat materials like titanium, refractory metals, and certain superalloys without degradation.

Ultimately, choosing a vacuum furnace is an investment in process control, ensuring the final material integrity matches the design intent.

Summary Table:

| Benefit | Description |

|---|---|

| Purity | Prevents oxidation, decarburization, and nitridation for clean, bright parts |

| Temperature Control | Ensures uniform heating through radiation and precise computer management |

| Repeatability | Guarantees consistent results with programmable cycles for every batch |

| Rapid Cooling | Enables fast, controlled quenching with inert gases for specific metallurgical properties |

| Energy Efficiency | Reduces heat loss and energy consumption compared to atmospheric furnaces |

| Versatility | Supports processes like brazing, hardening, and annealing for various materials |

Upgrade your laboratory's heat treatment capabilities with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—with strong deep customization to meet your unique experimental needs. Ensure purity, precision, and repeatability for your high-value applications in aerospace, medical devices, and more. Contact us today to discuss how we can enhance your process efficiency and material quality!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today