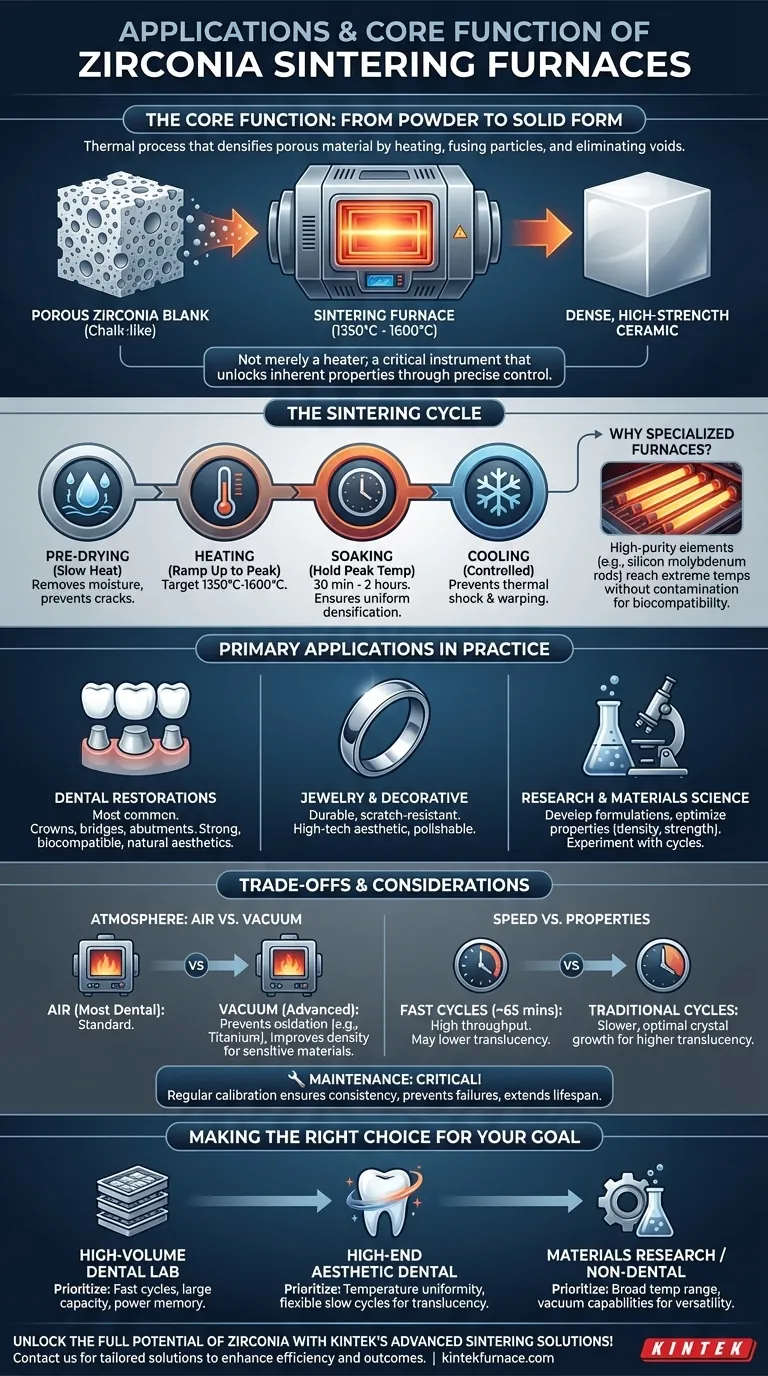

At their core, zirconia sintering furnaces are precision-engineered high-temperature ovens designed for one primary purpose: to transform porous, chalk-like zirconia blanks into a dense, high-strength, and aesthetically pleasing final ceramic. Their main applications are in the fabrication of dental restorations like crowns and bridges, the creation of durable jewelry components, and advanced materials research.

A sintering furnace is not merely a heater; it is a critical instrument that unlocks the inherent properties of zirconia. The precise control of temperature and time is what enables the material to achieve its renowned strength, durability, and biocompatibility for medical and industrial use.

The Core Function: From Powder to Solid Form

Sintering is a thermal process that densifies a porous material by heating it to a high temperature, just below its melting point. During this process, the individual zirconia particles fuse together, eliminating the voids between them and shrinking the object to its final, hardened state.

The Sintering Cycle Explained

A typical cycle consists of several meticulously controlled stages to ensure a defect-free outcome.

- Pre-drying: A slow initial heating phase removes any residual moisture from the zirconia structure, preventing cracks.

- Heating: The temperature is ramped up to the target sintering temperature, which typically falls between 1350°C and 1600°C.

- Soaking: The furnace holds the peak temperature for a set duration, often from 30 minutes to two hours. This "soaking" ensures uniform heat distribution and complete densification throughout the material.

- Cooling: The cooling phase is controlled slowly to prevent thermal shock, which could cause warping or cracking in the final product.

Why Zirconia Requires Specialized Furnaces

Standard ovens cannot meet the demands of zirconia. These furnaces are built with high-purity heating elements, such as dental silicon molybdenum rods, that can reach extreme temperatures without contaminating the material. This is essential for achieving the translucency and biocompatibility required for dental applications.

Primary Applications in Practice

The combination of strength and beauty makes sintered zirconia a valuable material across several industries.

Dental Restorations

This is the most common application. Dentists and dental labs use these furnaces to create crowns, bridges, and implant abutments. The process yields restorations that are strong enough to withstand chewing forces and have a natural, tooth-like appearance.

Jewelry and Decorative Components

The durability and scratch resistance of sintered zirconia make it an excellent material for jewelry. It can be polished to a high shine and offers a modern, high-tech aesthetic.

Research and Materials Science

In a laboratory setting, these furnaces are used to develop new ceramic formulations and optimize material properties. Researchers can experiment with different sintering cycles to study the effects on density, strength, and other characteristics.

Understanding the Trade-offs and Considerations

While powerful, these furnaces operate on a series of trade-offs that every user must understand to achieve their desired outcome.

Atmosphere Control: Air vs. Vacuum

Most dental zirconia is sintered in an air atmosphere. However, some advanced ceramics and metal powders require a vacuum furnace. A vacuum prevents oxidation, which is critical for oxygen-sensitive materials like titanium alloys or certain electronic components, resulting in improved density and mechanical properties.

Speed vs. Final Properties

Modern furnaces offer "fast sintering" cycles that can be completed in as little as 65 minutes. While this dramatically increases throughput, there can be a trade-off. Ultra-fast cycles may sometimes result in lower translucency compared to slower, traditional cycles that allow for more optimal crystal growth.

The Importance of Maintenance

These are precision instruments. Regular calibration and maintenance are non-negotiable to ensure the furnace consistently hits its target temperatures. Failure to do so can lead to inconsistent results, failed restorations, and a shorter lifespan for the equipment.

Making the Right Choice for Your Goal

Selecting a furnace depends entirely on your specific objectives and workflow demands.

- If your primary focus is a high-volume dental lab: Prioritize furnaces with fast, programmable cycles, large capacity, and a power-interruption memory function to maximize throughput.

- If your primary focus is high-end aesthetic dental restorations: Select a furnace with proven temperature uniformity and flexible programming to run slower cycles that maximize material translucency.

- If your primary focus is materials research or non-dental applications: Consider a versatile furnace with a broader temperature range and potential vacuum capabilities to accommodate a wider variety of materials.

Ultimately, choosing the right furnace is about selecting the precise tool to reliably unlock the full potential of your zirconia material.

Summary Table:

| Application | Key Features | Temperature Range |

|---|---|---|

| Dental Restorations | High strength, biocompatibility, natural aesthetics | 1350°C - 1600°C |

| Jewelry Components | Durability, scratch resistance, high polish | 1350°C - 1600°C |

| Materials Research | Customizable cycles, vacuum options for advanced ceramics | 1350°C - 1600°C |

Unlock the full potential of your zirconia materials with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, whether for high-volume dental labs, aesthetic restorations, or cutting-edge research. Contact us today to discuss how our tailored solutions can enhance your efficiency and outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency