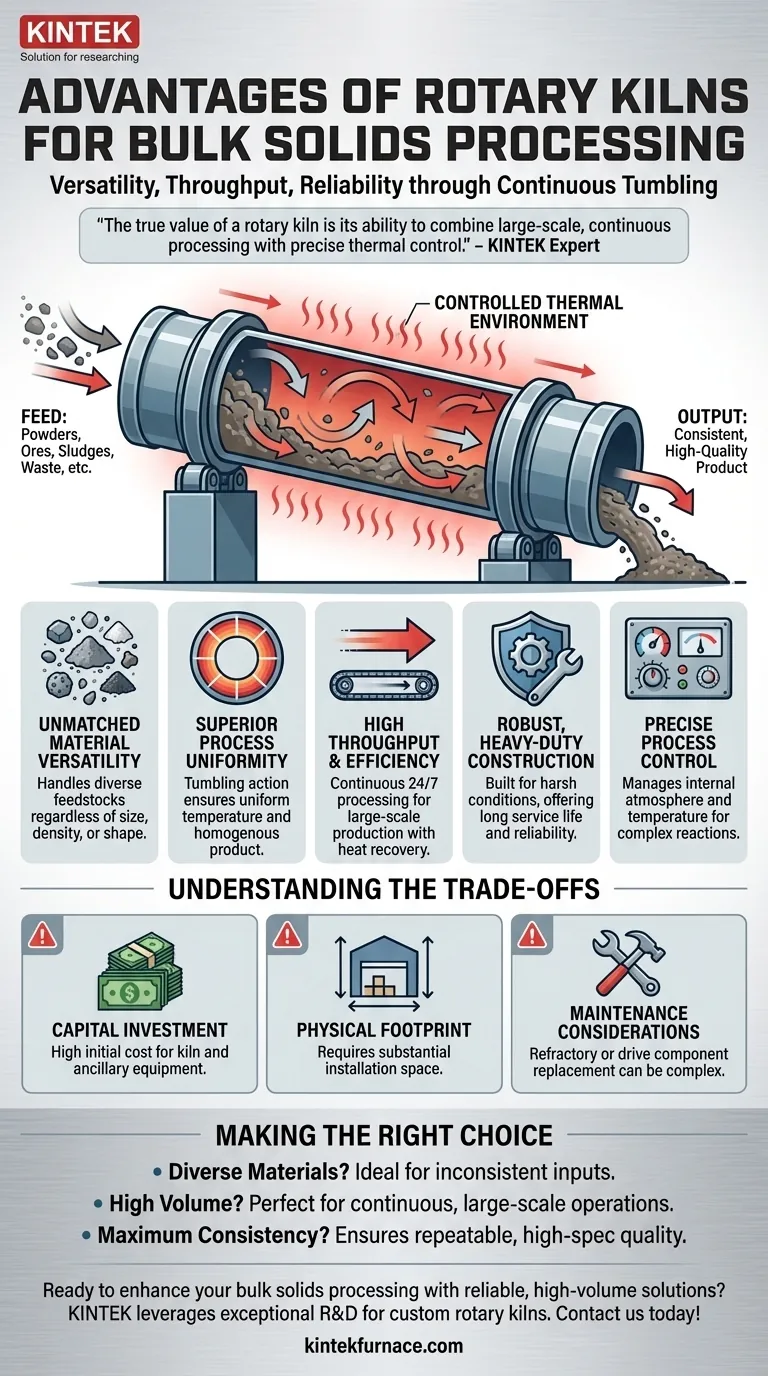

At their core, rotary kilns provide three primary advantages for bulk solids processing: exceptional material versatility, high-volume throughput, and robust operational reliability. They achieve this by tumbling material through a heated, rotating cylinder, ensuring uniform processing and consistent quality even under the most demanding industrial conditions.

The true value of a rotary kiln is its ability to combine large-scale, continuous processing with precise thermal control. This unique synthesis makes it the definitive solution for industries that cannot compromise on product quality, operational uptime, or production volume.

Why Rotary Kilns Excel in Material Processing

To understand the advantages of a rotary kiln, you must first understand its fundamental mechanism: continuous tumbling. Material is fed into one end of a slightly inclined, rotating drum. As it tumbles, it travels slowly toward the other end, ensuring every particle is exposed to the controlled thermal environment.

Unmatched Material Versatility

A key advantage of the rotary kiln design is its ability to handle an incredibly wide range of feedstocks.

The system is mechanically simple and robust, making it indifferent to variations in particle size, density, or shape. This allows it to effectively process everything from fine powders and filter cakes to minerals, ores, sludges, and chemical waste.

Superior Process Uniformity

The tumbling action is critical for achieving a homogenous final product. It continuously mixes the material bed, eliminating hot spots and ensuring uniform temperature distribution.

This constant agitation ensures that thermal reactions or phase changes happen consistently throughout the entire batch. The result is a highly repeatable process that delivers predictable, high-quality output, which is crucial for meeting stringent industrial specifications.

Engineered for Industrial Demands

Rotary kilns are not laboratory instruments; they are heavy industrial machines designed for relentless, 24/7 operation. Their engineering reflects a focus on performance, reliability, and control at scale.

High Throughput and Thermal Efficiency

Rotary kilns are designed for continuous processing, allowing for extremely high throughput compared to batch-based systems.

Modern designs can achieve high thermal efficiency by optimizing heat transfer to the material bed and recovering waste heat. This, combined with rapid temperature adjustment capabilities, makes them an economical choice for large-scale production.

Robust, Heavy-Duty Construction

Built from thick steel shells and often lined with refractory materials, rotary kilns are engineered to withstand extreme temperatures and abrasive or corrosive materials.

This heavy-duty construction results in a very long service life and exceptional reliability, minimizing downtime in critical production environments.

Precise Process Control

Despite their size, rotary kilns offer a high degree of control. The drum is sealed, enabling precise management of the internal atmosphere, whether it needs to be oxidizing, inert, or reducing.

Combined with sophisticated temperature monitoring, this allows operators to create and maintain the narrow process windows required for complex chemical reactions or material transformations.

Understanding the Trade-offs

While powerful, rotary kilns are not a universal solution. An objective assessment requires acknowledging their limitations.

Significant Capital Investment

The robust engineering and large scale of a rotary kiln system translate to a high initial capital cost. This includes not just the kiln but also the extensive ancillary equipment for material handling, off-gas treatment, and controls.

Large Physical Footprint

These are large, heavy machines that require substantial space for installation and operation. The necessary upstream and downstream equipment further adds to the overall plant footprint.

Maintenance Considerations

While known for reliability, when maintenance is required—such as replacing the refractory lining or drive components—it can be a complex and time-consuming process that necessitates a major plant shutdown.

Making the Right Choice for Your Goal

Selecting a rotary kiln depends on matching its core strengths to your primary operational objective.

- If your primary focus is processing diverse or difficult materials: The kiln's tolerance for varied feedstocks and its uniform heating make it the ideal choice for creating a consistent product from an inconsistent input.

- If your primary focus is achieving high-volume, continuous production: The kiln's ability to run 24/7 with minimal supervision delivers the high throughput necessary for large-scale industrial operations.

- If your primary focus is ensuring maximum product consistency: The combination of controlled tumbling, precise temperature zones, and atmosphere management gives you the repeatable quality required for high-spec materials.

Ultimately, a rotary kiln is the premier choice when your process demands a scalable, reliable, and precise thermal solution.

Summary Table:

| Advantage | Description |

|---|---|

| Material Versatility | Handles diverse feedstocks like powders, minerals, and waste with ease. |

| High Throughput | Enables continuous, large-scale processing for 24/7 industrial operations. |

| Process Uniformity | Ensures consistent quality through tumbling action and uniform heating. |

| Robust Reliability | Built for durability with long service life in harsh conditions. |

| Precise Control | Allows management of temperature and atmosphere for complex reactions. |

Ready to enhance your bulk solids processing with reliable, high-volume solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including custom rotary kilns tailored for industries like mining, chemicals, and waste management. Our expertise ensures precise thermal control and operational efficiency to meet your unique needs. Contact us today to discuss how we can optimize your production!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency