At their core, crucible furnaces are valued for their exceptional versatility, precise temperature control, and operational simplicity. These advantages make them a cost-effective and highly flexible solution for melting a wide range of materials in small to medium-sized batches, from precious metals and alloys to glass and ceramics.

A crucible furnace's primary advantage is not its capacity, but its agility. It excels in environments where precision, material variety, and the ability to adapt quickly are more critical than sheer production volume.

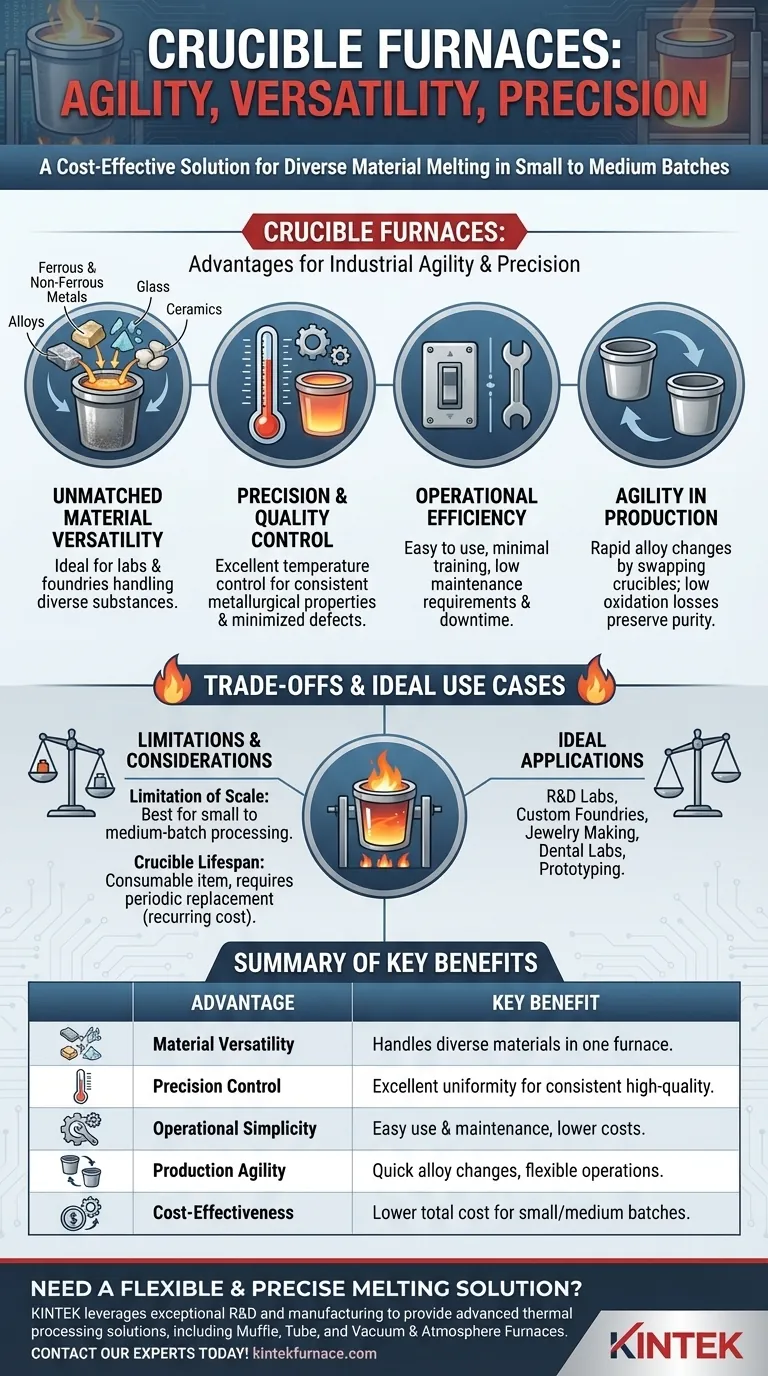

The Core Advantages Explained

Crucible furnaces provide a unique combination of benefits that make them indispensable in specific industrial, laboratory, and artisanal settings. Understanding each advantage clarifies their ideal role.

Unmatched Material Versatility

The fundamental design of a crucible furnace, where the material is contained within a separate pot (the crucible), allows it to handle an incredibly diverse range of substances. This includes ferrous and non-ferrous metals, various alloys, glass, and even ceramics.

This versatility makes them a go-to choice for operations that do not focus on a single material, such as research labs, custom foundries, and educational institutions.

Precision and Quality Control

Crucible furnaces offer excellent and often rapid temperature control. This precision is critical for achieving specific metallurgical properties, ensuring casting consistency, and preventing material degradation.

Furnaces using graphite crucibles are particularly noted for their fast heating speeds and temperature uniformity. This level of control minimizes defects and ensures the final product meets stringent quality standards.

Operational Efficiency

A major advantage is their ease of use and low maintenance requirements. Operators typically require minimal training, which lowers labor costs and reduces the risk of error.

Their straightforward design also simplifies maintenance, leading to less downtime and a lower total cost of ownership over the furnace's lifespan.

Agility in Production

The use of a self-contained crucible allows for rapid changes between different alloys. You can simply swap out the crucible to begin melting a new material, a process that is slow and difficult in other furnace types.

Furthermore, the contained melt environment results in low oxidation losses. This protects the molten material from the surrounding atmosphere, preserving its purity and reducing waste.

Understanding the Trade-offs and Ideal Use Cases

While their advantages are significant, crucible furnaces are not a universal solution. Acknowledging their limitations is key to making a correct assessment for your needs.

The Limitation of Scale

Crucible furnaces are best suited for small to medium-batch processing. Their capacity is inherently limited by the size of the crucible.

For large-scale, continuous industrial production demanding high volumes of a single alloy, other technologies like large induction or arc furnaces are generally more efficient and economical.

Crucible Lifespan as a Recurring Cost

While the furnace itself is low-maintenance, the crucible is a consumable item. It has a finite lifespan and will need to be replaced periodically.

This recurring operational cost must be factored into any economic evaluation. The lifespan can vary significantly based on the crucible material, the temperatures used, and the type of material being melted.

Ideal Applications

Given their profile, crucible furnaces excel in specific environments. They are the standard for jewelry making, dental labs, and small-scale metalworking.

Industrially, they are widely used in foundries for creating custom parts, in the automotive and electronics sectors for prototyping and small production runs, and in R&D labs for materials testing.

Making the Right Choice for Your Operation

To determine if a crucible furnace is the right fit, align its strengths with your primary operational goals.

- If your primary focus is flexibility and varied production: A crucible furnace is an ideal choice due to its ability to handle different materials and allow for quick alloy changes.

- If your primary focus is precision and material quality: The excellent temperature control makes this furnace a superior option for applications where material properties are critical.

- If your primary focus is a small-scale operation or R&D: The compact size, ease of use, and cost-effectiveness for smaller batches make it a perfect fit.

- If your primary focus is high-volume, single-material melting: You should evaluate larger-scale furnace technologies, as a crucible furnace may become a bottleneck.

Ultimately, choosing the right furnace requires a clear understanding of your specific production needs, budget, and quality requirements.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Material Versatility | Handles diverse materials (metals, alloys, glass, ceramics) in one furnace. |

| Precision Control | Excellent temperature uniformity for high-quality, consistent results. |

| Operational Simplicity | Easy to use and maintain, reducing labor costs and downtime. |

| Production Agility | Quick alloy changes and low oxidation losses for flexible operations. |

| Cost-Effectiveness | Ideal for small to medium batches with a lower total cost of ownership. |

Need a flexible and precise melting solution for your lab or small-scale production?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal processing solutions. Whether your work involves precious metals, alloys, or advanced ceramics, our high-temperature furnaces—including Muffle, Tube, and Vacuum & Atmosphere Furnaces—are engineered for precision and reliability.

Our strong deep customization capability allows us to tailor a system to your unique experimental or production requirements, ensuring you get the performance and versatility you need.

Contact our experts today to discuss how we can optimize your melting process!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Induction Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability