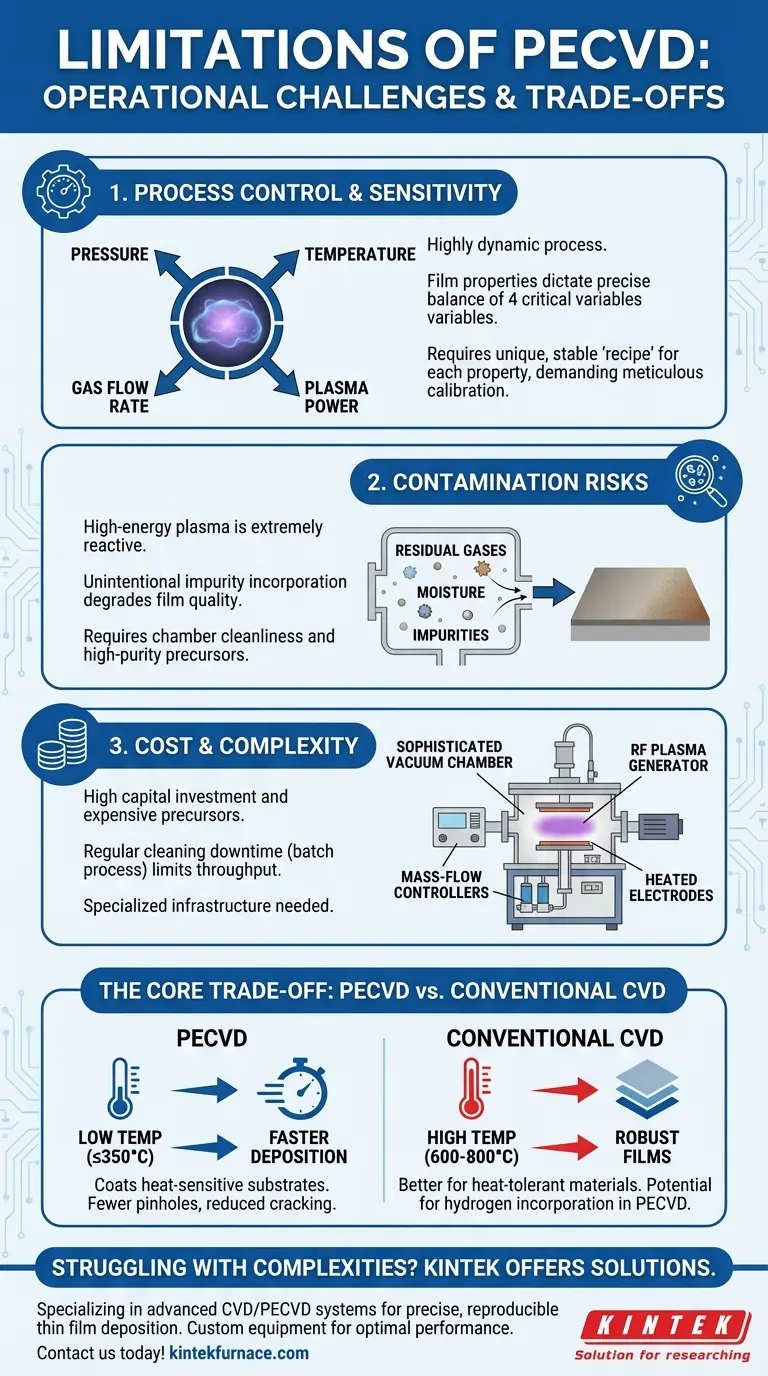

While powerful, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is not without its operational challenges. The primary limitations of PECVD are its extreme sensitivity to process parameters, a high susceptibility to contamination, and the significant cost and complexity of the required equipment. These factors demand a high level of process control to achieve stable and reproducible results.

The core trade-off of PECVD is accepting higher operational complexity and cost in exchange for its signature benefit: the ability to deposit high-quality, uniform thin films at low temperatures on materials that could not withstand other thermal processes.

The Core Challenge: Process Control and Reproducibility

PECVD is a highly dynamic process. Its success hinges on the precise and stable control of multiple interdependent variables, making it more of a complex "recipe" than a simple procedure.

The Four Critical Variables

The properties of the final film are dictated by a delicate balance between four key parameters: pressure, temperature, gas flow rate, and plasma power. A small deviation in any one of these can significantly alter the film's density, stress, chemical composition, and electrical characteristics.

The "Recipe" Problem

Achieving a specific film property requires developing a unique and stable process recipe. Maintaining this stability run-to-run and day-to-day is a significant operational challenge, demanding meticulous calibration and system maintenance.

High Sensitivity to Contamination

The high-energy plasma environment is extremely reactive. Any residual gases, moisture, or impurities within the vacuum chamber can be unintentionally incorporated into the film, degrading its quality and performance. This makes chamber cleanliness and high-purity precursor gases absolutely critical.

Understanding the Trade-offs: PECVD vs. Conventional CVD

To understand PECVD's limitations, it's useful to compare it to its thermal counterpart, conventional Chemical Vapor Deposition (CVD).

The Temperature Advantage

The defining advantage of PECVD is its low deposition temperature (often 350°C or below), compared to the 600-800°C required for thermal CVD. This allows for coating heat-sensitive substrates like plastics or semiconductor wafers with pre-existing circuitry without causing thermal damage.

The Speed and Quality Benefit

PECVD generally offers much faster deposition rates than conventional CVD. The resulting films often have fewer pinholes and a reduced risk of cracking because the low temperature minimizes thermal stress.

The Hidden Cost of Plasma

While the low temperature is a benefit, the plasma itself can be a limitation. For instance, hydrogen from precursor gases can be incorporated into the film, which can be an undesirable impurity for certain high-performance optical or electronic applications.

Practical and Economic Limitations

Beyond the physics of the process, several practical and economic factors limit the application of PECVD.

High Capital Investment

PECVD systems are complex and expensive. They require a sophisticated vacuum chamber, multiple mass-flow controllers for precise gas handling, an RF plasma generator, and heated electrode assemblies. This represents a significant upfront capital cost.

Precursor Material Costs

The specialized chemical gases (precursors) used in PECVD can be expensive, and some may be hazardous. This contributes to the overall operational cost and requires specialized infrastructure for safe handling and storage.

Maintenance and Throughput

The plasma process necessitates regular chamber cleaning to remove deposited material from the chamber walls, which creates downtime. As a batch process, the time spent loading, pumping down, depositing, and unloading substrates can limit the overall factory throughput.

Making the Right Choice for Your Goal

Selecting the correct deposition technology requires aligning its capabilities and limitations with your specific objective.

- If your primary focus is coating temperature-sensitive substrates: PECVD is often the superior or only viable choice due to its low-temperature process.

- If your primary focus is depositing simple, robust films on heat-tolerant materials: Conventional thermal CVD or a physical deposition method (PVD) might be a more cost-effective solution.

- If your primary focus is achieving the highest possible film purity for advanced applications: You must carefully manage PECVD's potential for contamination or consider alternative high-purity methods.

Understanding these limitations allows you to leverage PECVD's distinct advantages for the right applications, ensuring both technical success and economic viability.

Summary Table:

| Limitation | Key Details |

|---|---|

| Process Control | High sensitivity to pressure, temperature, gas flow, and plasma power; requires precise recipe development and stability. |

| Contamination | Plasma environment is reactive, leading to impurity incorporation; demands high chamber cleanliness and pure gases. |

| Cost & Complexity | High capital investment for equipment; expensive precursors and maintenance; batch processing limits throughput. |

| Trade-offs | Low-temperature advantage vs. potential hydrogen incorporation; slower throughput compared to alternatives. |

Struggling with PECVD's complexities? KINTEK specializes in advanced high-temperature furnace solutions, including CVD/PECVD systems, to help you achieve precise, reproducible thin film deposition. With our deep customization capabilities, we tailor equipment to your unique needs, ensuring optimal performance and cost-efficiency. Contact us today to discuss how we can enhance your laboratory's productivity!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- How does the PECVD process work? Enable Low-Temperature, High-Quality Thin Film Deposition